The prospect of Brazilian customers purchasing metal round tube polishing machines for polishing coated tubes is quite optimistic. Here are some reasons:

Demand growth: With the continuous advancement of industrialization and urbanization, Brazil's demand for metal products continues to grow. Plating tubes, as a common metal product, have a wide range of applications in fields such as architecture, furniture, and automobiles, so the requirements for polishing processes are also increasing.

Technological upgrading: Brazil's manufacturing industry is gradually undergoing technological upgrading, and the requirements for improving product quality, production efficiency, and environmental friendliness are also constantly increasing. The use of a metal tube polishing machine for polishing can meet these requirements and is in line with the development trend of the Brazilian market.

- Cost control: Automated polishing equipment can improve production efficiency, reduce labor costs, and make the production process more cost-effective, which is in line with the interests of manufacturing enterprises.

-

- Environmental requirements: Brazil's environmental requirements are gradually increasing, and automated polishing equipment is beneficial for enterprises to comply with environmental regulations in reducing waste generation and saving energy.

-

- National policy support: Some countries may provide a certain degree of policy support for the introduction of new equipment and upgrading of technology in the manufacturing industry, which will also help promote the demand for metal tube polishing machines.

-

In summary, the purchase of metal round tube polishing machines by Brazilian customers for polishing coated tubes has good prospects, which is in line with current market demand and development trends.

In December 2018, faced with the huge market demand for polished round tubes, Mr. Diego from a large Brazilian metal processing company realized that the existing mechanical equipment and product capacity were far from meeting the company's development needs. In addition to the intelligent development in the era of technology and mechanical manufacturing, she learned that unlike manual polishing of pipes, circular pipe polishing machines have significantly higher efficiency and efficiency in polishing metal circular pipes, and the effect is many times better than manual polishing. The polishing effect is good and the productivity is greatly improved.

In December 2018, Mr. Diego searched for the term "round tube polishing machine" on Alibaba and found a metal round tube grinding and polishing machine product from Xingtai Xieli Machinery Manufacturing Email Company. He told Mr. Liu, the technical director of Xingtai Xieli Machinery, his requirements for round tube workpieces and that he wanted to find a four station fully automatic round tube polishing machine. The diameter of his workpiece is 25-50mm, and the length is 300-750mm. The original surface roughness of the workpiece is 0.20-0.25, and the state after polishing is Ra0.12 (+-0.03). There is a centerless grinder already in use in their company. Firstly, he will grind his pipes with a centerless grinder. But his polishing process is still manual polishing.

So he wants to use a tube polishing machine to polish the surface of the tube after being ground by a centerless grinder. After polishing, the tube needs to undergo a 67 hrc hard winding/ After plating, it will be polished again by this polishing machine. At this time, the first polishing head needs to be turned off, and only the second, third, and fourth polishing heads need to be used for polishing.

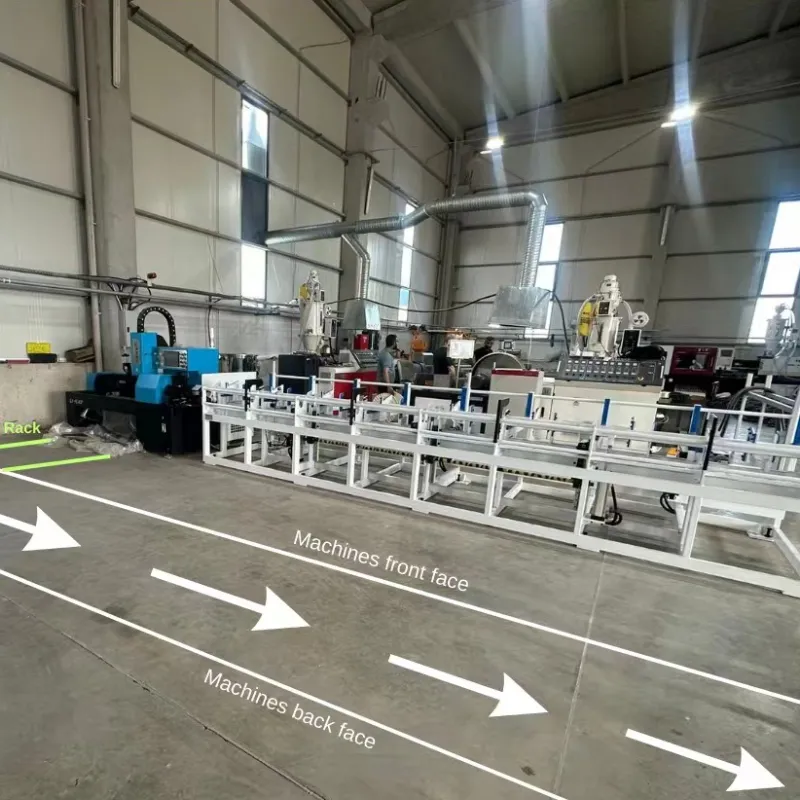

The first communication left a good impression on both parties. After detailed communication with Mr. Diego, Mr. Liu from the technical department explained the advantages and characteristics of modern mechanical equipment production lines to him. According to Mr. Diego's requirements, he selected a fully automatic four station round pipe polishing machine and matched it with an automatic loading and unloading rack. The first group of grinding heads, the second group of grinding heads, and the third group of grinding heads were respectively equipped with sand belts for polishing, and the fourth group of grinding heads were equipped with a thousand blade wheel for polishing. And Mr. Liu tailors the size of the machine according to the usage area of Diego's factory, so that the four station round pipe polishing machine can be placed reasonably in the Diego factory with automatic feeding machine and automatic unloading machine.

In January 2019, Mr. Liu designed a complete set of plans and drawings for Diego as agreed, and Diego expressed great satisfaction, which was exactly the result he wanted. In the same year and month, both parties reached an agreement and signed a contract.

Therefore, Diego followed the development of the times and chose to purchase professional fully automatic circular tube grinding and polishing machine processing equipment. The use of machine production instead of manual processing ensures rapid growth in sales.

In February 2019, the fully automatic four station round pipe polishing machine was produced according to the agreed time by both parties. This machine was first sent to the port of Shanghai and then to the port of Santos in Brazil. At present, the round pipe polishing machine equipment is running well in Brazil.

The use of a round tube polishing machine for polishing at a plating tube processing plant in Brazil has the following advantages:

- Improve product quality: The round tube polishing machine can provide high-precision polishing effects, allowing the surface of the plated tube to achieve high smoothness and glossiness, thereby improving the quality and appearance of the product.

-

- Increase production efficiency: The use of a round pipe polishing machine can automate the polishing process, greatly reducing manual operations, improving production efficiency, shortening processing cycles, and reducing production costs.

-

- Save human resources: The automation operation of the round pipe polishing machine reduces the need for manual operation, while reducing labor intensity and protecting the physical health of workers.

- Optimize the process flow: The use of polishing machines can make the polishing process more standardized and precise, which is beneficial for controlling product quality and improving production efficiency.

-

- Improve production environmental friendliness: Automated polishing technology can reduce environmental pollution, save energy, and reduce waste generation, which is beneficial for production environmental protection.

-

Overall, using a round tube polishing machine for polishing in plated tube processing plants in Brazil can improve product quality, increase production efficiency, save human resources, optimize process flow, and enhance production environmental friendliness. These advantages have made the round tube polishing machine widely used in the electroplating tube processing industry.