-

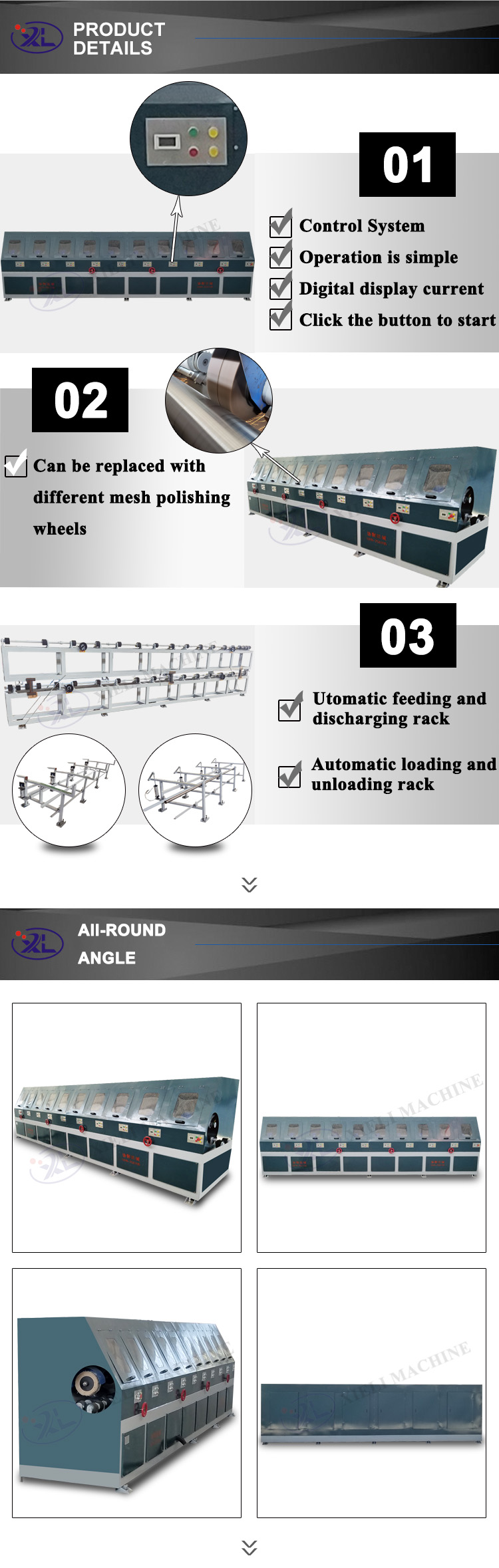

Products Detail

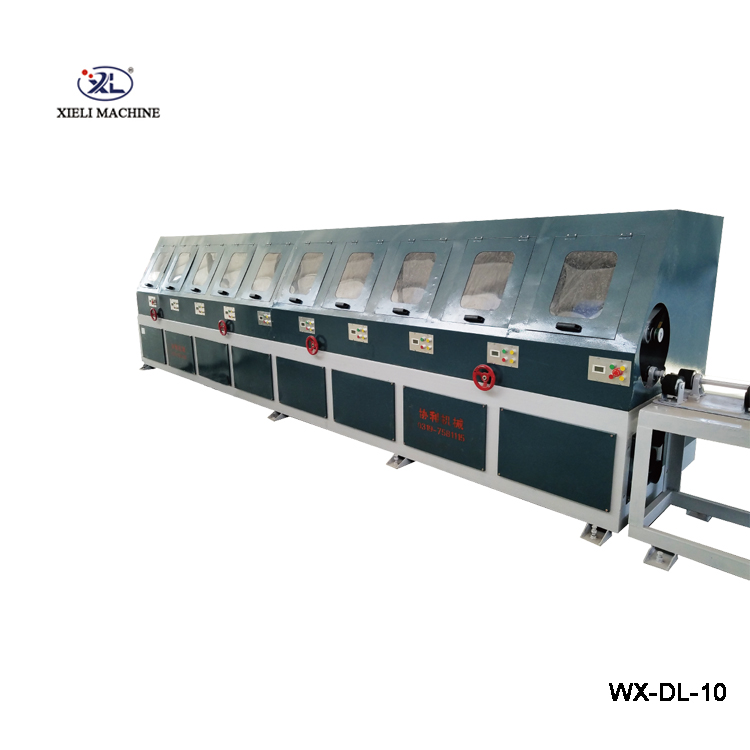

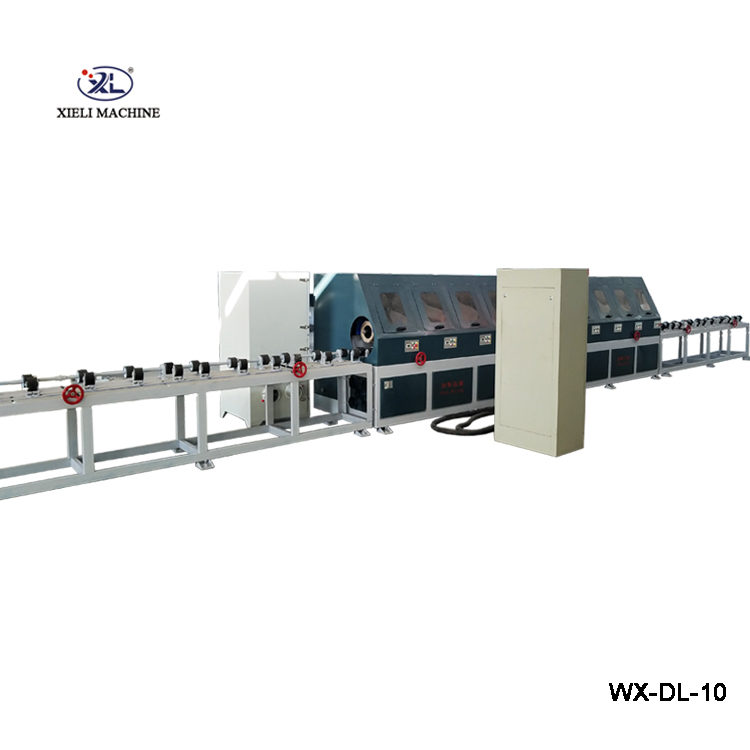

WX-DL series large diameter hydraulic tube polishing machine

Main purpose and scope of application:

Round pipe polishing machine is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. A variety of brown and white corundum grinding wheels and polishing wheels such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA, etc. can be installed in the round tube polishing machine. The guide wheel has stepless speed control, which is simple and convenient to operate. The steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dust removal fan or a wet dust removal system, which can be matched with an automatic feeding and unloading mechanism according to the length of the processed parts. This device It can be equipped with grinding wheel to grind pin and remove oxide skin (peeling off) on the surface of round steel and pipe with serious defects.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DL-2

WX-DL-4

WX-DL-6

WX-DL-8

WX-DL-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

13.2

22.2

30.7

38.7

46.7

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel

specification(mm)

110

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

20-360

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Processing length(mm)

Determined by bracket length (0.3-12)

Dry fan dust removal

optional

Wet water cycle dust removal

optional

Grinding head

feeding mode

Digital display electromagnetic hydraulic control

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weight about(kg)

2000

3000

4000

5000

6000

Equipment dimension(m)

1.3*1.2*1.5

2.6*1.2*1.5

3.9*1.2*1.5

5.2*1.2*1.5

6.5*1.2*1.5

Round tube polishing machine is also known as centerless polishing machine, centerless outer polishing machine, round tube outer polishing machine, slender shaft polishing machine. It is mainly used for rust removal and polishing of hardware production, vehicle parts, steel and wood furniture, instrument machinery, standard parts and other occupations before and after electroplating.

It is the best choice for polishing round pipe, round rod and slender shaft. According to the shape of the workpiece can be divided into plane polishing machine, ball polishing machine, square tube polishing machine, strip polishing machine. According to its polishing process, it can be divided into a single group of cylindrical polishing machine and multiple groups of vertical cylindrical polishing machine and multiple groups of horizontal polishing machine.

Round pipe polishing machine is a kind of mechanical equipment used for polishing and rust removal of round pipes. Application range of round tube polishing machine: mainly used in automobile, motorcycle, bicycle, household appliances and other manufacturing industries.

The principle of polishing is to rely on mechanical force to obtain a certain roughness of the surface of the polished workpiece to reduce the roughness value of the surface of the part and the friction resistance; At the same time, due to the heat generated in the grinding process, it plays a lubricating role, thus improving the wear resistance and fatigue strength of the workpiece.

The working process is as follows:

- Place the metal workpiece to be processed on the turntable (can also be fixed by fixture), and adjust the position;

- After starting the power switch button, rotate the handwheel to make the turntable rotate slowly (pay attention to observe whether the motor steering is correct);

- Stop rotating when the turntable turns to a certain Angle, and then inject the working liquid into the inner hole of the workpiece by manual or electric means (pay attention not to pour too much to avoid overflow and damage to the equipment), and then continue to rotate the handwheel to the required Angle;

- According to different needs, different speed and pressure can be set to meet different requirements;

- When the set pressure and time are reached, it can automatically stop working and enter the cooling state.

- If you need to replace a new workpiece, you can complete the entire processing process by re-operating it according to the above steps.

- After use, turn off the power switch and drain the water in the sink before leaving the site.

- This machine is suitable for deburring and chamfering of steel pipes of various materials.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Afrika

- Albania

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Asụsụ Bosnia

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Asụsụ Croatia

- Czech

- Danish

- Dutch

- Bekee

- Esperanto

- Estonia

- Asụsụ Finnish

- French

- Onye Frisian

- Onye Galisi

- Asụsụ Georgian

- German

- Grik

- Gujarati

- Haitian Creole

- Hausa

- Hawaian

- Hibru

- Mba

- Miao

- Asụsụ Hungarian

- Aislandi

- igbo

- Asụsụ Indonesian

- Irish

- Ịtali

- Japanese

- Asụsụ Javanị

- Kannada

- kazakh

- Khmer

- Onye Rwandan

- Korean

- Kurdish

- Kyrgyz

- Ịrụ ọrụ

- Latịn

- Latvia

- Lithuania

- Luxembourgish

- Masedonia

- Malagasy

- Malay

- Malayalam

- Malta

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Asụsụ Persia

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Asụsụ Serbian

- Bekee

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Asụsụ Sudan

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- onye Ukraine

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Enyemaka

- Yiddish

- Zulu