-

Products Detail

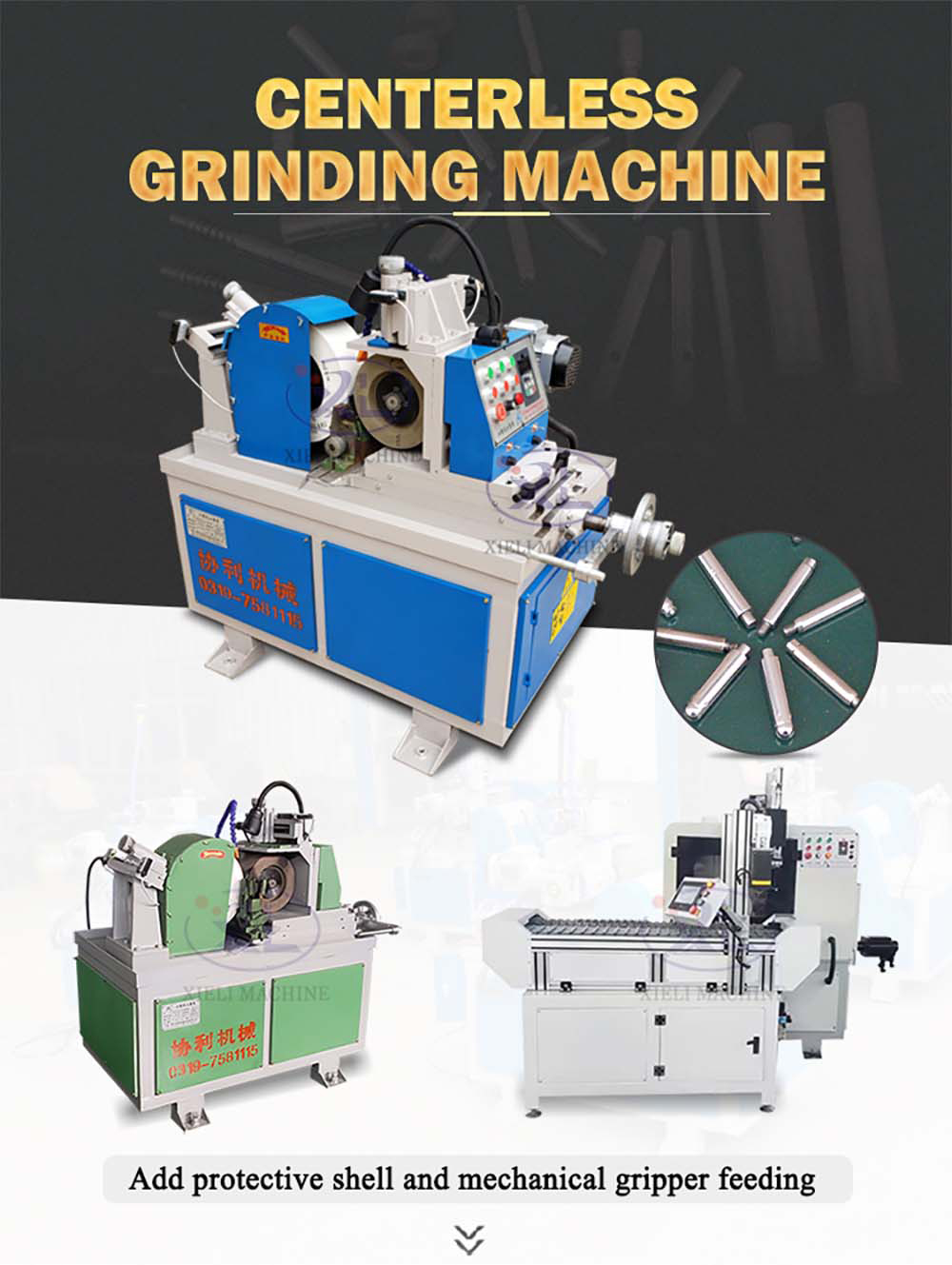

WX-M2-60 CNC Centerless Grinding Machine Features

* The width of the grinding wheel guide wheel is 125mm, with a larger grinding amount and better stability.

* The layout of the CNC centerless grinder adopts the single-sided movement mode of regulating the wheel frame.

* The sand wheel shaft adopts an overhang structure, so it is convenient to replace the grinding wheel.

* Guide wheel shaft adopts overhang structure, easy to replace guide wheel.

* The regulating wheel adopts frequency conversion to adjust the speed, which can realize the feed speed of the workpiece with different diameters.

* The machine tool is equipped with a cutting mechanism, which can realize the grinding of the step surface and cone surface.

- * The machine tool can be equipped with a long workpiece through a grinding bracket.

- Automatic centerless grinding machines can be matched with a variety of automatic feeding equipment and automatic manipulators.

CNC Centerless Grinder's Main Purpose and Scope of Application:

- In addition to grinding with a grinding wheel, a PVA polishing wheel can be used to highlight and wet polish the workpiece.

* CNC centerless grinding machine is mainly used for grinding the cylindrical surface of various ring and shaft parts, and for semi-automatic and automatic cutting-grinding of various stepped, tapered, and cylindrical rotating surfaces.

CNC Centerless Grinding Machine Technical Parameters

WX-M2-60 Centerless Grinding Machine

Longitudinal feed grinding

Grinding workpiece diameter

0.8–60mm

Grinding length (max)

1000mm

Horizontal feed grinding

Grinding workpiece diameter

2–60mm

Grinding length (max)

125mm

Grinding wheel specification

P350*125*127

Guide wheel specification

P250*125*75

Grinding wheel rotating speed

2000r/min

Guide wheel rotating speed

stepless5-240r/min

Guide wheel rotary angle

In the vertical plane

-2° -5°

In the horizontal plane

-10°-10°

Standard test bar

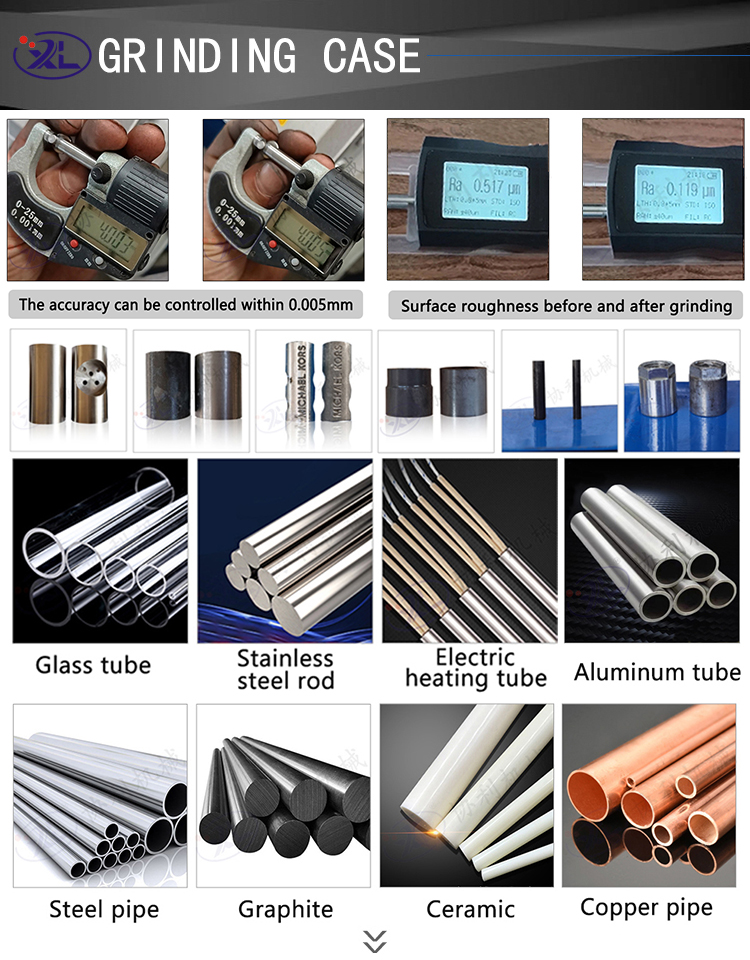

grinding accuracy

(ø 20× 75 )

Roundness

2 μ m

Cylindricity

3 μ m

Roughness

Ra0.2 μ m

Grinding feed

Feed amount of each grid of dial 0.002mm

Cooling pump flow

25L/min

Equipment power 5KW

Grinding wheel motor

4.0kw

Guide wheel motor

0.75kw

Cooling pump motor

0.09kw

Machine tool lead-in power supply

Three phase four wire 380V 50Hz

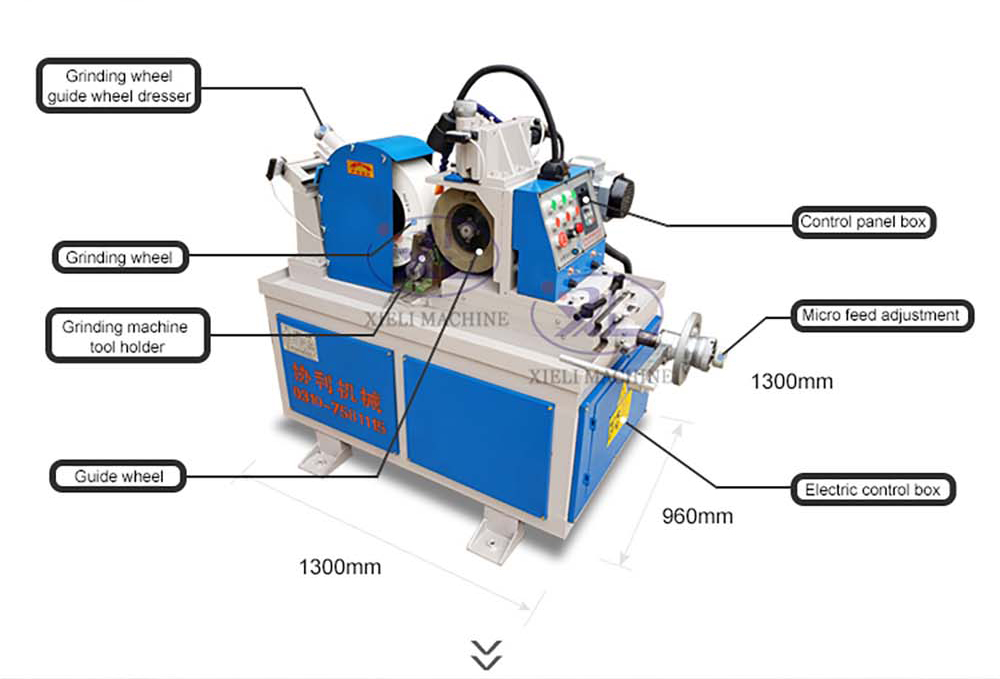

Machine dimension

1300*960*1300mm

Machine tool weight approx

1000kg

The workpiece is grinding by feeding along the axis of the grinding wheel. Adjust the small inclination Angle of the guide wheel axis to realize the axial feed of the workpiece. Suitable for grinding slender cylindrical workpieces. Short shaft, short sleeve and other workpieces without center hole. Insert centerless grinding. The support plate is provided with an axial positioning fulcrum, the workpiece is supported on a certain position of the support plate, and the grinding wheel or guide wheel is cut into for grinding. It is used for grinding workpieces with shoulders and heads, and also for grinding rotating parts such as cones and spheres. The productivity of a centerless grinding machine is higher. Suitable for mass production and easy to automate.

* The width of the grinding wheel and guide wheel of the centerless grinder is 125mm, with a large grinding amount and good stability.

* The layout of the centerless grinder adopts the single-sided movement mode of the guide wheel frame.

* Centerless grinding machine sand wheel shaft adopts an overhang structure, easy to replace the grinding wheel.

* The guide wheel shaft of the centerless grinder adopts a pendant structure to facilitate the replacement of the guide wheel.

* The guide wheel of the centerless grinder adopts frequency conversion speed regulation, which can realize the feed speed of the workpiece with different diameters.

* The centerless grinding machine is equipped with a cutting mechanism, which can realize the grinding of the step surface and cone surface.

* A centerless grinding machine can assemble long workpieces through a grinding bracket.

- The centerless grinding machine can be equipped with various automatic feeding equipment and automatic manipulators.

CNC Centerless Grinding Machine Application

Precision Machining: When tight tolerances and smooth surface finishes are essential, CNC centerless grinders are frequently employed in precision machining operations. They are excellent in precisely grinding cylinder components to specifications.

Automotive Industry: A variety of components, including shafts, pistons, and other cylindrical parts, are ground using CNC centerless grinding machines in this industry. The engine and transmission components will operate as intended thanks to the precision attained.

Aerospace Manufacturing: To produce parts like turbine blades and landing gear shafts, among other essential components, the aerospace sector uses CNC centerless grinding. Maintaining the safety and functionality of aeronautical equipment requires a high degree of precision.

Medical Device Manufacturing: Precision is paramount in the production of medical devices. CNC centerless grinders are used for grinding surgical implants, instruments, and other components that require exact dimensions and smooth surfaces.

Bearing Manufacturing: In the production of bearings, where precision and surface finish are vital, CNC centerless grinding machines play a crucial role. They ensure the accuracy and quality of bearings used in various machinery.

Tool and Die Industry: CNC centerless grinding is applied in the manufacturing of cutting tools and dies. It helps achieve sharp edges and precise geometries, enhancing the performance of tools used in machining and manufacturing processes.

General Engineering: CNC centerless grinding machines are utilized in general engineering for grinding various cylindrical components, such as rods, tubes, and shafts. This versatility makes them suitable for a wide range of applications in different industries.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Afrika

- Albania

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Asụsụ Bosnia

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Asụsụ Croatia

- Czech

- Danish

- Dutch

- Bekee

- Esperanto

- Estonia

- Asụsụ Finnish

- French

- Onye Frisian

- Onye Galisi

- Asụsụ Georgian

- German

- Grik

- Gujarati

- Haitian Creole

- Hausa

- Hawaian

- Hibru

- Mba

- Miao

- Asụsụ Hungarian

- Aislandi

- igbo

- Asụsụ Indonesian

- Irish

- Ịtali

- Japanese

- Asụsụ Javanị

- Kannada

- kazakh

- Khmer

- Onye Rwandan

- Korean

- Kurdish

- Kyrgyz

- Ịrụ ọrụ

- Latịn

- Latvia

- Lithuania

- Luxembourgish

- Masedonia

- Malagasy

- Malay

- Malayalam

- Malta

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Asụsụ Persia

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Asụsụ Serbian

- Bekee

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Asụsụ Sudan

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- onye Ukraine

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Enyemaka

- Yiddish

- Zulu