What Is A Polishing Machine Used For?

A polishing machine is used to improve the surface finish of materials by smoothing, shining, and removing imperfections such as scratches, oxidation, or roughness. It works by applying abrasive materials or polishing compounds to a workpiece, often using rotating or oscillating pads, wheels, or belts. The goal is to create a clean, smooth, and often reflective surface, enhancing both the appearance and functionality of the item.

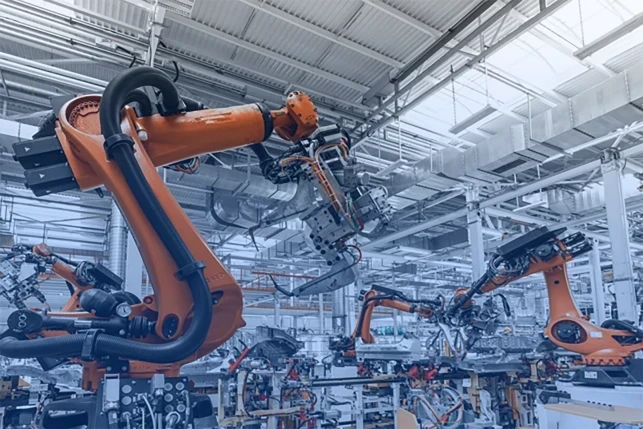

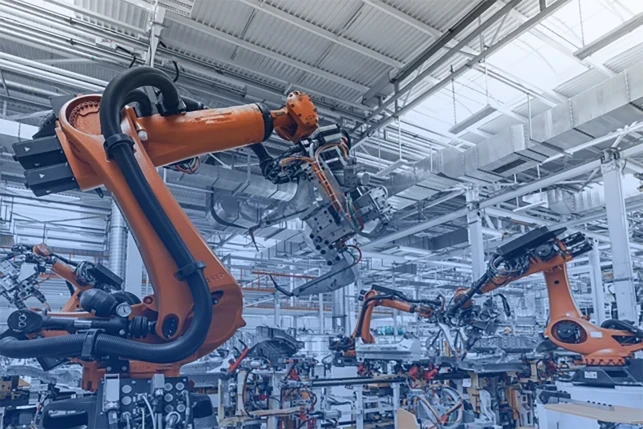

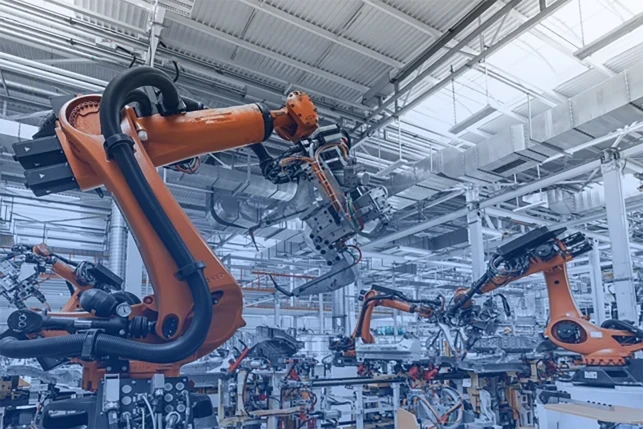

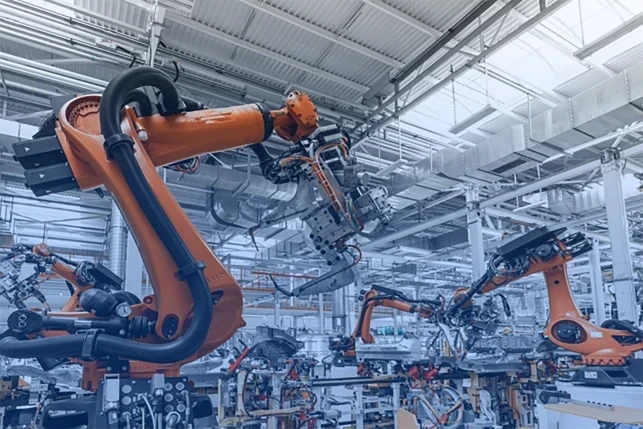

Polishing machines are widely used in various industries, including metalworking, automotive, electronics, jewelry, and woodworking. In metalworking, for example, they remove surface defects from metal parts, improve corrosion resistance, and prepare surfaces for further treatment like painting or plating. In automotive manufacturing, polishing machines help achieve glossy finishes on car bodies and components. In electronics, polishing is critical for producing smooth, flat surfaces on circuit boards and semiconductor wafers.

Different types of polishing machines exist, including bench polishers, orbital polishers, rotary polishers, and belt polishers, each suited for specific tasks and materials. Some machines use wet polishing techniques, which apply water or other liquids to reduce heat and dust, improving the finish and protecting the workpiece.

What Is The Difference Between A Grinder And A Polisher?

The main difference between a grinder and a polisher lies in their purpose and the finish they produce on a workpiece. A grinder is primarily used for material removal, shaping, or smoothing rough surfaces through abrasive cutting. It uses coarse abrasives to quickly remove metal or other materials, often to prepare the surface for further processing or to achieve a specific shape or dimension. Grinding is typically a more aggressive process that can leave a rough or matte surface.

In contrast, a polisher is designed to create a smooth, shiny, and often reflective surface by removing fine scratches, oxidation, or minor imperfections. Polishing is a finer process than grinding and uses softer abrasives or polishing compounds applied with pads, wheels, or belts. The goal of polishing is to improve the appearance and surface quality rather than to remove large amounts of material.

Grinders are commonly used in the initial stages of manufacturing or repair, such as removing welds, shaping metal parts, or preparing surfaces. Polishers are used in the finishing stages to enhance aesthetics and surface smoothness, such as producing a mirror-like finish on metal, plastic, or wood.

In summary, grinding focuses on heavy material removal and shaping, while polishing emphasizes surface refinement and shine. Both processes are essential but serve different roles in manufacturing and finishing workflows.