- Introduction to Precision Tube Polishing Solutions

- Innovative Technology Driving Efficiency

- Key Manufacturers in the Industry

- Customization for Diverse Industrial Needs

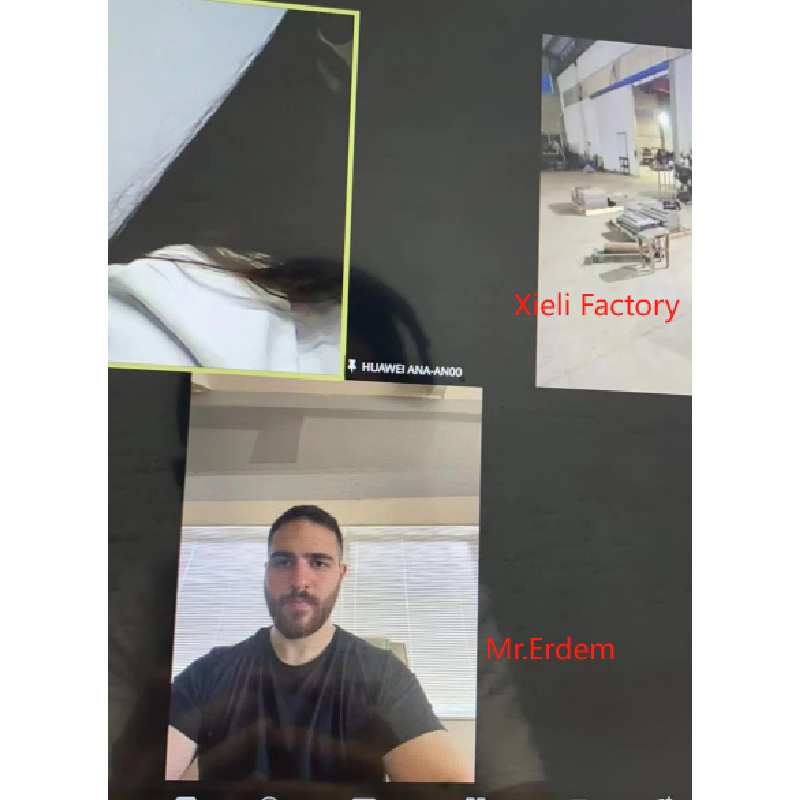

- Real-World Applications & Success Stories

- Future Trends in Surface Finishing

- Why Partner with Leading Tube Polishing Machine Manufacturers?

(tube polishing machine manufacturer)

Precision Tube Polishing Solutions for Modern Industries

In today's high-stakes manufacturing landscape, tube polishing machine manufacturer

s play a pivotal role in delivering surface finishing systems that meet ISO 9001:2015 standards. The global market for metal polishing equipment is projected to grow at a 5.8% CAGR through 2030, driven by demand from aerospace, automotive, and medical sectors. Advanced systems now achieve surface roughness values below Ra 0.1µm, enabling manufacturers to comply with strict FDA and ASME specifications.

Innovative Technology Driving Efficiency

Modern tube polishing machines integrate AI-powered quality control sensors and adaptive pressure systems that reduce material waste by up to 22%. The latest models feature:

- Multi-axis robotic arms with ±0.003mm positioning accuracy

- Energy-efficient direct-drive motors cutting power consumption by 35%

- Closed-loop coolant systems recycling 98% of process fluids

Key Manufacturers in the Industry

| Manufacturer | Max Workpiece Diameter | Surface Finish Range | Production Capacity |

|---|---|---|---|

| TechGrind Systems | Ø300mm | Ra 0.05-1.2µm | 120 units/month |

| PolishPro Industries | Ø150mm | Ra 0.1-2.0µm | 80 units/month |

Customization for Diverse Industrial Needs

Leading SS pipe polishing machine manufacturer manufacturers offer modular designs that adapt to specific requirements:

- Medical-grade systems with cleanroom compatibility

- Explosion-proof configurations for oil/gas applications

- High-volume automotive setups processing 150+ tubes/hour

Real-World Applications & Success Stories

A recent implementation for a German auto parts supplier resulted in:

- 78% reduction in post-processing defects

- 15% faster cycle times through automated loading

- ROI achieved in 14 months

Future Trends in Surface Finishing

The next generation of centerless grinder blades will incorporate diamond-like carbon coatings extending service life by 300%. Emerging technologies include:

- Machine learning algorithms predicting wheel wear

- Hybrid ultrasonic-mechanical polishing systems

Why Partner with Tube Polishing Machine Manufacturers?

Top-tier tube polishing machine manufacturers provide comprehensive support packages including:

- On-site installation and operator training

- 24/7 remote diagnostics

- Warranty extensions up to 5 years

(tube polishing machine manufacturer)

FAQS on tube polishing machine manufacturer

Q: How to choose a reliable tube polishing machine manufacturer?

A: Prioritize manufacturers with certifications like ISO, proven industry experience, and positive client reviews. Ensure they offer after-sales support and customized solutions.

Q: What features should a top ss pipe polishing machine manufacturer provide?

A: Look for compatibility with stainless steel, adjustable polishing speeds, and durable construction. Advanced models should include automation and dust-control systems.

Q: Why is a specialized centerless grinder blades manufacturer important?

A: Precision blades ensure consistent grinding and extend machine lifespan. Certified manufacturers use high-grade materials and rigorous quality checks for optimal performance.

Q: Can tube polishing machine manufacturers customize equipment for unique needs?

A: Yes, reputable manufacturers often tailor machine dimensions, power, and polishing heads. Provide detailed specifications for bespoke solutions.

Q: What certifications should a centerless grinder blades manufacturer have?

A: Seek ISO 9001 certification and compliance with industry standards like CE. These ensure adherence to safety, quality, and environmental regulations.

-

Precision Tube Polishing Machines Manufacturer Durable & EfficientNewsMay.21,2025

-

Discount Cincinnati 2EA 220-8 Centerless Grinder High Precision & AffordableNewsMay.21,2025

-

High-Precision Stainless Steel Tube Polishing Machine OEM & China DiscountNewsMay.21,2025

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025