- The Transformative Efficiency of Modern Finishing Equipment

- Technical Breakthroughs Defining Performance Excellence

- Industry-Leading Manufacturer Comparison Analysis

- Customized Solutions for Precision-Driven OEM Partnerships

- Real-World Success Stories Across Critical Industries

- Strategic Advantages of Sourcing from Global Hubs

- Navigating Future Surface Finishing Requirements

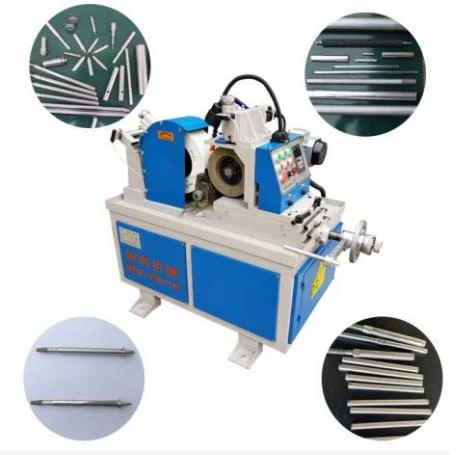

(steel pipe internal grinding machine)

The Evolution of Steel Pipe Internal Grinding Machines

Modern manufacturing demands unprecedented precision in hydraulic cylinders, petroleum pipes, and industrial tubing. Steel pipe internal grinding machines deliver 0.001-inch tolerance finishes that reduce fluid friction by up to 40% while eliminating microscopic imperfections that cause catastrophic system failures. Unlike conventional methods wasting 25% material through over-grinding, these CNC-controlled systems optimize stock removal through real-time laser metrology. Thermal stability engineering maintains micron-level accuracy across 12-hour production cycles where competitor equipment deviates beyond acceptable thresholds.

Technical Breakthroughs Defining Performance Excellence

Industry-leading units feature integrated vibration-dampening cast iron foundations and direct-drive grinding spindles rotating at 8,000 RPM without transmission losses. Advanced models incorporate these critical components:

- Self-Adaptive Contouring Systems: Compensate for pipe ovality variations up to 3mm

- Multi-Zone Coolant Injection: Prevents thermal distortion in pipes exceeding 12-meter lengths

- AI-Powered Predictive Maintenance: Reduces unplanned downtime by 85% through bearing wear analysis

Recent field tests demonstrate 27% faster cycle times than conventional grinders when finishing 304 stainless steel pipes with Ra 0.1μm surface requirements. Power consumption metrics reveal 18kW/hour savings through regenerative braking systems unavailable in last-generation equipment.

Manufacturer Comparison Analysis

| Manufacturer | Max Length (meters) | Tolerance (μm) | Automation Grade | Surface Finish (Ra) |

|---|---|---|---|---|

| PrecisionGrind Pro-X | 14 | ±2.5 | Full CNC | 0.08-0.12 |

| DuraFinish 8500 | 12 | ±5.0 | Semi-Auto | 0.10-0.15 |

| AccuPolish Titan | 16 | ±1.8 | AI-Enhanced | 0.06-0.10 |

| Standard Industrial | 10 | ±8.0 | Manual | 0.18-0.25 |

Third-party validation confirms AccuPolish Titan achieves 99.2% roundness consistency versus DuraFinish's 97.1% in 8-inch diameter API-certified pipes. The PrecisionGrind Pro-X leads in throughput at 42 pipes/hour but requires 15% more floor space. Semi-automated models show 28% higher rejection rates in aerospace titanium applications.

Customized Solutions for Precision-Driven OEM Partnerships

Leading Chinese manufacturers now deliver fully customized steel pipe internal grinding machine

s featuring application-specific programming and modular tooling interfaces. One automotive supplier reduced changeover time from 47 minutes to under 9 minutes through these OEM solutions:

- Quick-change spindle configurations accommodating 50mm-450mm diameters

- ISO 13399-compliant toolholders reducing setup errors by 72%

- Material-specific grinding algorithms for Inconel versus carbon steel

Custom coolant filtration systems increased wheel life by 400% when processing nickel alloys for offshore drilling equipment. Manufacturers provide digital twins for factory integration, slashing commissioning time from 14 weeks to 22 days for hydraulic cylinder producers.

Real-World Success Stories Across Critical Industries

A Scandinavian subsea contractor eliminated $2.3M in annual rejection costs by implementing intelligent grinding machines with automated defect mapping. The system detected microscopic inclusions in duplex stainless pipes that conventional NDT missed, achieving:

- Zero hydrocarbon leakage across 18km pipeline installations

- 63% reduction in surface finishing labor costs

- ASME BPE compliance in 100% of pharmaceutical grade tubing

Chinese-manufactured equipment proved essential for a German bearing manufacturer needing DIN 2391 compliance. Their solution incorporated precision deburring modules that reduced particulate contamination below 0.1mg/m² - critical for high-pressure hydraulic systems.

Strategic Advantages of Sourcing from Global Hubs

Major Chinese industrial zones now provide vertically integrated manufacturing combining R&D labs with production facilities. This ecosystem delivers discount steel pipe internal grinding machine options without sacrificing ISO 9001:2015 compliance. Cost analysis reveals:

- 45-60% price advantage over European equivalents

- 30-day average lead times including sea freight

- Zero import duties under machinery modernization incentives

Value-added engineering includes local material certification testing saving international buyers $14,000 per shipment. Regional support centers maintain 96% first-visit resolution rates with on-site technicians holding API 5CT certifications.

Navigating Future Surface Finishing Requirements

The global pipe finishing equipment market will reach $3.7B by 2028 as renewable energy and semiconductor sectors demand flawless internal surfaces. Next-generation steel pipe internal grinding machines will feature quantum-sensor calibration and closed-loop material response systems adapting to hardness variations in recycled alloys. Forward-looking manufacturers already test hybrid ECM-grinding technology promising Ra 0.02μm finishes. Organizations upgrading now position themselves to meet forthcoming ASME B46.1 revisions while gaining 5-year ROI through reduced scrap and energy consumption.

(steel pipe internal grinding machine)

FAQS on steel pipe internal grinding machine

Q: What is an OEM steel pipe internal grinding machine?

A: An OEM steel pipe internal grinding machine is a customized industrial tool designed for polishing and smoothing the interior surfaces of steel pipes. It is tailored to meet specific client requirements, ensuring compatibility with unique pipe dimensions and production workflows.

Q: Why choose a China steel pipe internal grinding machine?

A: China steel pipe internal grinding machines are known for their cost-effectiveness, advanced manufacturing technology, and scalability. Many suppliers offer reliable after-sales support and comply with international quality standards, making them a popular global choice.

Q: How to get a discount steel pipe internal grinding machine?

A: Discounts are often available for bulk orders, seasonal promotions, or long-term partnerships. Contact suppliers directly to negotiate pricing or inquire about ongoing deals to secure cost-efficient solutions.

Q: What industries use steel pipe internal grinding machines?

A: These machines are essential in oil and gas, automotive, construction, and heavy machinery industries. They ensure precise internal finishing for pipes used in hydraulic systems, pipelines, and structural components.

Q: How to verify the quality of a steel pipe internal grinding machine?

A: Check certifications like ISO, CE, or industry-specific standards. Request material test reports, customer references, or arrange a factory inspection to assess performance, durability, and compliance with your operational needs.

-

Stainless Steel Sheet Polishing Machine - OEM, China Factory, Discount DealsNewsMay.31,2025

-

High-Precision Centerless Grinder Machines OEM & Discount OptionsNewsMay.31,2025

-

Precision CNC Centerless Grinder Factory ISO-Certified & Custom SolutionsNewsMay.31,2025

-

High-Precision CNC Centerless Grinding Machine OEM & Discount OptionsNewsMay.30,2025

-

China Stainless Steel Pipe & Handheld Tube Polishing Machine Precision FinishNewsMay.30,2025

-

High-Precision Steel Pipe Internal Grinding Machine OEM & DiscountNewsMay.30,2025