-

Products Detail

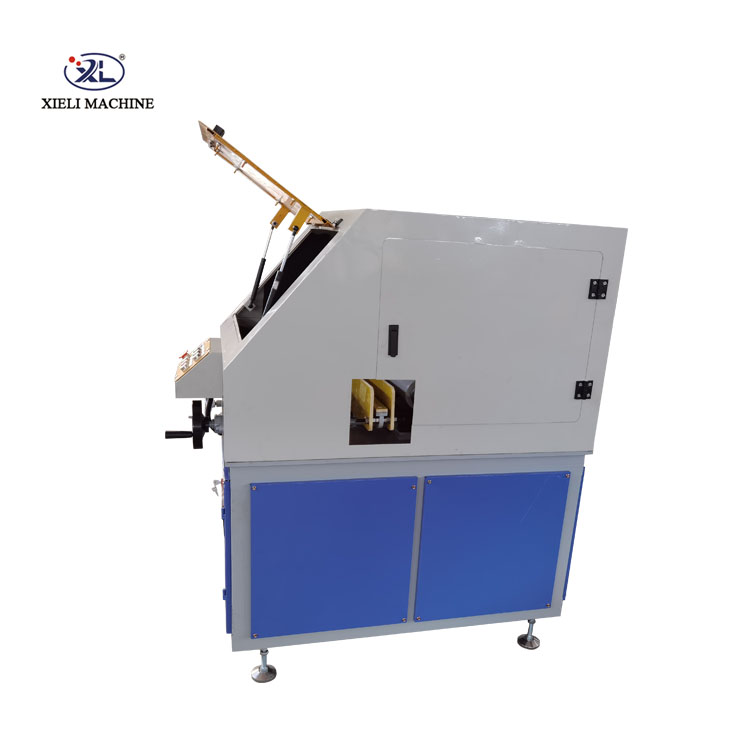

WX-DWZ Series Multi-station Round Tube Polishing Machine

Main purpose and scope of application:

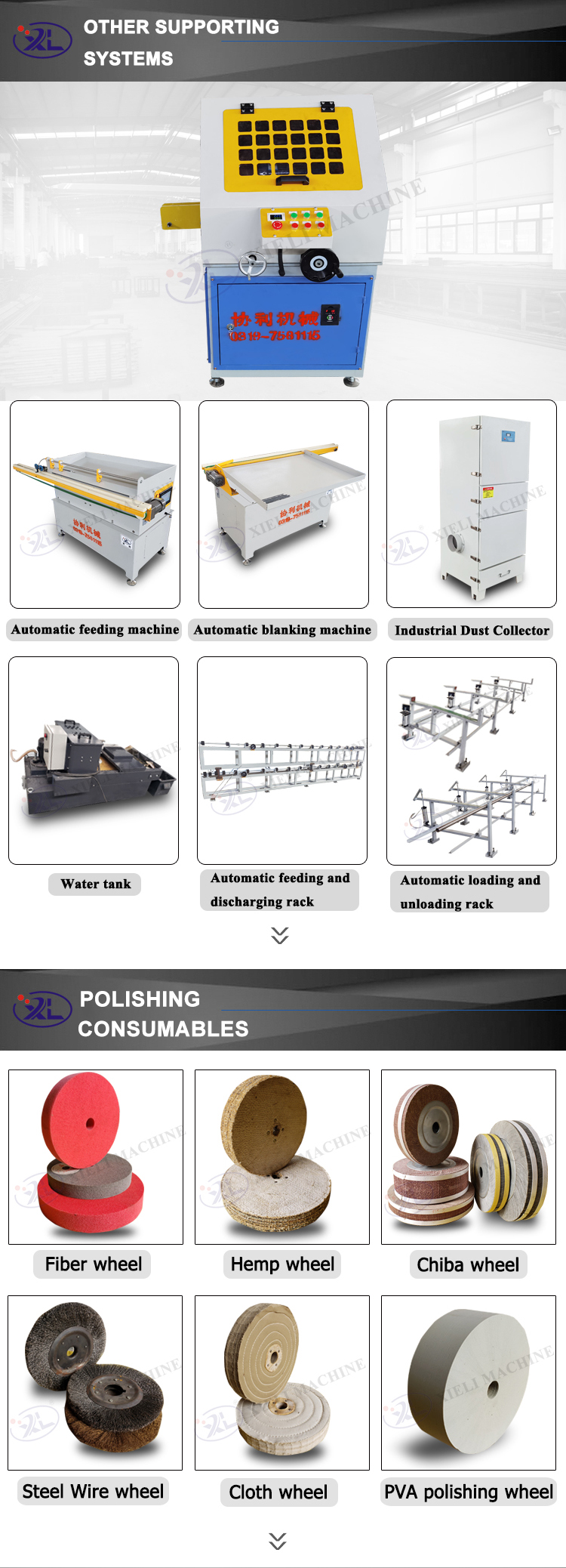

Round pipe polisher is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. Round pipe polisher is the best choice for polishing the round pipe, round rod and slender shaft. The round tube polisher can be equipped with a variety of polishing wheels, such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA etc. the guide wheel is stepless speed control, simple and convenient operation, and the steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dedusting fan or a wet dedusting system, which can be matched with an automatic loading and unloading mechanism according to the length of the processed parts.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DWZ-2

WX-DWZ-4

WX-DWZ-6

WX-DWZ-8

WX-DWZ-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

8.6

18

26.5

35.5

44

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel

specification(mm)

100*200

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

4-100

Processing efficiency(m/min)

0-20

Surface roughness (um)

Ra 0.02

Processing length(mm)

100-6000

Wet water cycle dust removal

optional

Dry fan dust removal

optional

Feeding mode of grinding head

Digital display electric adjustable

Machine tool Total weight about(kg)

800

1600

2400

3200

4000

Equipment Overall dimension(m)

1.4*1.2*1.0

2.6*1.2*1.0

3.8*1.2*1.0

5.0*1.2*1.0

6.2*1.2*1.0

The horizontal type of multi-station round pipe polishing machine mainly processes shorter workpieces with smaller diameters. The operation is simple, the speed is stepless speed regulation drive, suitable for polishing different requirements of the change and adjust the transmission speed.

Mainly for crafts processing plant, hardware processing plant, bathroom processing plant, electronic processing plant and other customer groups to use. Horizontal cylindrical tube polishing machine to achieve automatic surface polishing treatment, suitable for small workpieces, metal workpieces automatic polishing surface gloss and burr removal.

It has the characteristics of high efficiency, good finish and wide range of abrasive consumables. It should be noted that during the polishing process, do not reach into the polishing area, and the machine must be turned off when replacing or correcting the polishing wheel, and then operate after completely continuous work.

The characteristics of the round tube polishing machine: the round tube polishing machine has high efficiency, good finish, and generally high quality and low price of die consumables. The machine has the advantages of simple and convenient operation, stable product characteristics and low noise, etc.

Products to consider different technical applications can be installed circulating water system and dust collector dust removal equipment. The machine can also reserve the exhaust fan port consumers can also install their own dust collector.

The multi-station round pipe polishing machine has the advantages of simple operation, stable product performance and low noise, and is well received by the majority of users. Optional cooling system and dust collection system are used to meet different industries.

Reserved fan ports Users can also install dust removal fans by themselves. A wide range of durable consumables, multi-station round tube polishing machine guide wheel rotation using stepless speed regulation, can better meet the different diameters, different lengths of workpiece grinding or polishing.

High efficiency, good finish, abrasives and consumables are widely durable, etc., polishing system adopts multi-stage polishing arrangement, and the amount of advance can be adjusted separately. Because the guide wheel of the machine rotates by stepless speed regulation, the polishing workpiece is more efficient, the finish is better, and the abrasive consumables are extensive and durable.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- africano

- albanés

- Amárico

- árabe

- armenio

- azerbaiyano

- vasco

- bielorruso

- bengalí

- bosnio

- búlgaro

- catalán

- Cebuano

- Porcelana

- China (Taiwan)

- corso

- croata

- checo

- danés

- Holandés

- Inglés

- esperanto

- estonio

- finlandés

- Francés

- frisio

- gallego

- georgiano

- Alemán

- Griego

- Gujarati

- criollo haitiano

- Hausa

- hawaiano

- hebreo

- No

- Miao

- húngaro

- islandés

- igbo

- indonesio

- irlandés

- italiano

- japonés

- javanés

- Canarés

- kazajo

- Jemer

- Ruandés

- coreano

- kurdo

- Kirguistán

- Mano de obra

- latín

- letón

- lituano

- luxemburgués

- macedónio

- madagascarí

- malayo

- Malabar

- maltés

- maorí

- Maratí

- mongol

- Myanmar

- Nepalí

- noruego

- noruego

- occitano

- Pastún

- persa

- Polaco

- portugués

- punjabi

- rumano

- ruso

- Samoano

- gaélico escocés

- serbio

- Inglés

- Shona

- Sindhi

- Cingalés

- eslovaco

- esloveno

- somalí

- Español

- Sundanés

- swahili

- sueco

- Tagalo

- Tayiko

- Tamil

- Tártaro

- Telugu

- tailandés

- turco

- turcomano

- ucranio

- Urdu

- Uigur

- uzbeko

- vietnamita

- galés

- Ayuda

- yídish

- zulú