Thai companies buying metal round tube polishers may bring many advantages, including but not limited to the following:

- Improve production efficiency: The metal tube polishing machine can automatically grind and polish, greatly improving production efficiency. Compared with manual processing, robotic processing can complete tasks faster and more accurately, thus saving time and labor costs.

- Improve product quality: The metal tube polishing machine can ensure the finish and accuracy of the pipe surface, and the quality of the pipe produced is more stable and unified, in line with the requirements of high standards of products, which is conducive to improving the competitiveness of enterprise products.

- Reduce human error: Machine processing can reduce errors and losses caused by human operation, improve production efficiency and ensure product quality and stability.

- Enhance the corporate image: The purchase of advanced metal tube polishing equipment shows that the enterprise attaches great importance to production quality and process technology, which helps to enhance the corporate image and brand value.

- Reduce costs: Although the purchase cost of metal tube polishing machine is higher, in the long run, more cost savings can be brought by improving production efficiency, reducing labor costs, and reducing scrap rates.

Therefore, the purchase of metal tube polishing machine for Thai enterprises, not only can improve production efficiency and product quality, but also reduce costs, enhance the corporate image, these advantages will help the sustainable development of enterprises and enhance competitiveness.

In 2015, a Thai stainless steel pipe processing manufacturer inquired about Xingtai Xieli Machinery Manufacturing Co., LTD. 's products in China through Alibaba. In May of the same year, Mr. Lai, the representative of the Thai stainless steel pipe processing company, was sent to Xieli Machinery Company in Xingtai, Hebei Province, to investigate the equipment performance of the stainless steel round pipe polishing machine and the effect of polishing the stainless steel round pipe.

Mr. Lai, the representative of the Thai stainless steel pipe processing company, said that the metal round pipe grinding and polishing machine has a wide range of applications in the construction and decoration industry in Thailand. The processing amount of stainless steel round pipe is very large, and it requires a certain precision and the finish of the round pipe. Take into account local industry characteristics and other relevant technical requirements.

Xingtai Xieli Machinery Manufacturing Co., Ltd. as a professional metal grinding and polishing machine design, manufacturing, research and development and production in one of the machinery manufacturing enterprises, always to product upgrade, service upgrade, to create value for users of the concept of practice.

After Xieli machinery production workers overtime production and manufacturing, we successfully completed the stainless steel round tube polishing machine equipment and delivery on time before July 5, 2015, and guaranteed the quality. The representative of the stainless steel pipe processing company came to Xingtai Xieli Machinery Factory for acceptance of the machine before delivery, and watched the whole process of loading. Then we transported the stainless steel round pipe polishing machine, first to the port of Tianjin, and then to the port of Bangkok, Thailand.

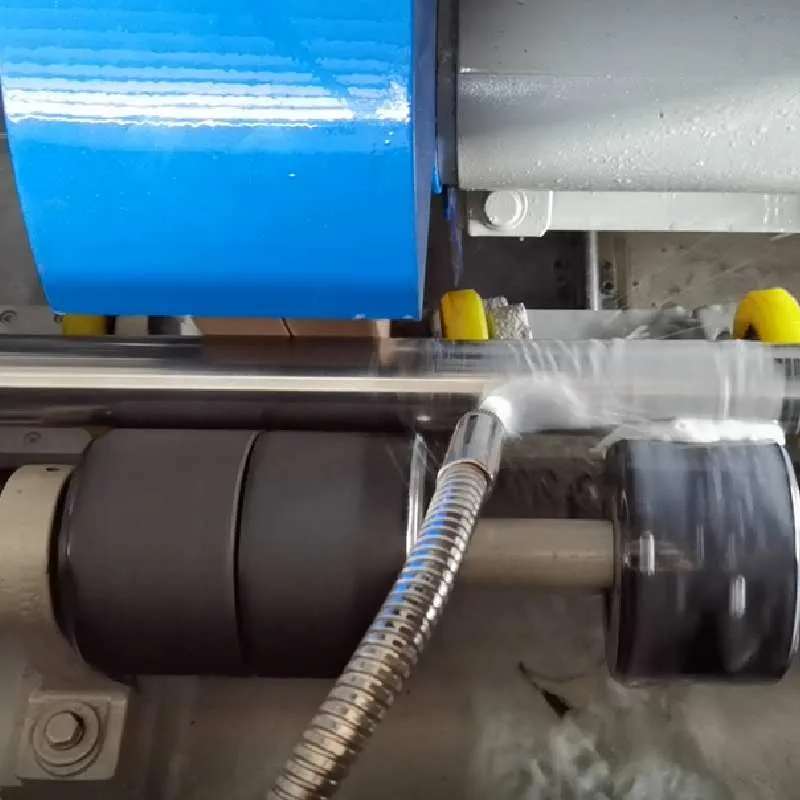

The following picture shows the loading process:

Metal tube grinding and polishing machine in Thailand application market, metal tube grinding and polishing machine is a special equipment for grinding and polishing metal tube, widely used in the field of industrial manufacturing. In Thailand, with the rapid development of industrialization and the continuous growth of manufacturing industry, metal tube grinding and polishing machine has been widely used in the market, and has shown great potential for development.

First of all, the metal tube grinding and polishing machine is widely used in the stainless steel manufacturing industry in Thailand. As one of the important manufacturing centers in Southeast Asia, Thailand's stainless steel manufacturing industry has a high level of development. The metal tube grinding and polishing machine can improve the surface finish and accuracy of stainless steel pipes, meet the production needs of stainless steel manufacturing industry for high-quality pipes, and play an important role in the market.

Secondly, the metal tube grinding and polishing machine is also widely used in the construction and decoration industry in Thailand. With the rapid development of the construction industry in Thailand and the increasing demand for high-quality stainless steel pipes, the metal round pipe grinding and polishing machine has become an indispensable equipment in the production process. It can grind and polish stainless steel pipes to improve their surface finish and quality, meeting the needs of the construction and decoration industry for beautiful and durable pipes.

Looking forward to the future, with the acceleration of Thailand's industrialization process and the continuous development of manufacturing industry, the market application prospects of metal round tube grinding and polishing machine in Thailand will be broader. Especially in the fields of food processing, chemical and energy, the demand for high standard metal pipes will continue to increase, thus driving the demand for metal round pipe grinding and polishing machines. Therefore, for the equipment manufacturer, the Thai market will be a market full of development potential and opportunities, worthy of focus and investment.

In short, the metal tube grinding and polishing machine in the Thai market has broad application prospects, with the further development of Thailand's industrial manufacturing industry, the demand for this equipment will continue to grow.