The demand prospects for centerless grinding of step workpieces in the Indonesian market are positive. With the development of the automotive, furniture, and mechanical parts industries, the demand for precision machining processes is also increasing. Grinding step workpieces with centerless grinders is a key component used for processing these industries, therefore there is a high demand in the market.

Especially with the continuous growth of the Indonesian economy, the demand for cars, furniture, and mechanical parts is also increasing, which will further drive the market demand for centerless grinding of step workpieces. In addition, with the further development of the manufacturing industry, the demand for high-precision and high-quality components will also increase, which will provide more opportunities for the market of centerless grinders grinding step workpieces.

Therefore, it can be foreseen that the prospect of centerless grinding of step workpieces in the Indonesian market is positive and is expected to continue to grow with the development of related industries. For enterprises engaged in this field, there will be many business opportunities and development opportunities.

In 2023, Mr. Yin from a large metal polishing and grinding company located in Indonesia searched for keywords related to centerless grinding machine on online platforms, found Xingtai Xieli Machinery Manufacturing Co., Ltd., and issued an inquiry to gain a preliminary understanding of equipment processing information.The initial close communication laid the foundation for future friendly cooperation.

Mr. Yin has a large metal processing company in Indonesia, mainly engaged in polishing and grinding of various metals such as round tubes, square tubes, and flat plates. And the finished product is used in various fields.

At present, Mr. Yin is using a large-scale centerless grinder in a certain country. However, due to the continuous increase in production capacity, Mr. Yin wants to add new centerless grinder equipment to the company. Therefore, on behalf of the company, Mr. Yin searched for fully automatic CNC centerless grinding machine and automatic feeding machine devices on platforms such as Google and Alibaba.

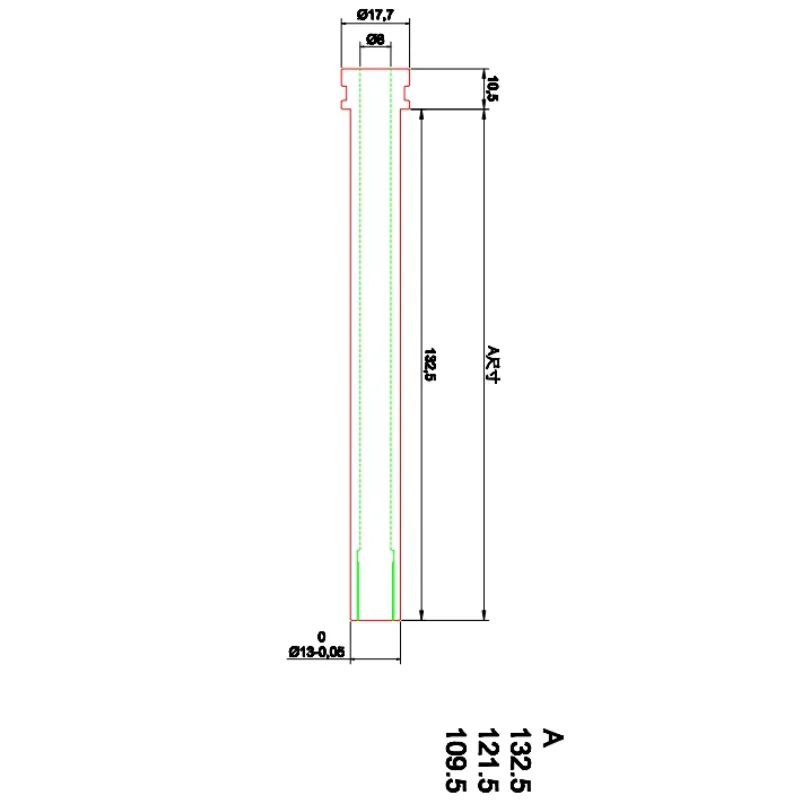

Mr. Yin sent the specifications and drawings of the workpiece to Mr. Liu. The workpiece he used for centerless grinding is an iron pipe with steps, with a diameter of 6mm. For length, there are 109.5mm,121.5mm and 132.5mm.

The centerless grinding machine of Xingtai Xieli Machinery grinds workpieces with steps, and the theoretical length should be within the range of 125mm. But Mr. Yin's other size of 132.5mm has exceeded 125mm. So, Mr. Liu from Xieli Machinery discussed this plan with the professional technical personnel of Xieli Machine, and tailored a grinding method for Yin Zongzong. It can grind 125mm long iron pipes as well as 132.5mm long iron pipes, and also enable the mechanical gripper automatic feeding machine to be compatible with both sizes. After Mr. Liu sent the design proposal to Mr. Yin, he expressed satisfaction and believed in the professionalism of Xieli Machinery.

So on that day, Mr. Yin from Indonesia and Mr. Liu from Xieli Machinery signed a contract and paid the equipment deposit.

After signing the contract, Manager Liu quickly made the drawings and arranged for the production workshop to produce fully automatic CNC centerless grinding machines and automatic feeding machine devices.

The following image shows the physical product after production

Twenty days later, the machine production was completed and the machine was sent from Xingtai Xieli Machinery Factory to the Shenzhen warehouse, which then sent it by air to Indonesia.

Due to the fact that most of Indonesia's Yin Corporation uses WeChat chat, the Indonesian side and Xingtai Xieli Machinery have formed a group chat on the WeChat APP for technical personnel to follow up on subsequent technical issues. After using the machine in Indonesia for a period of time, Mr. Yin provided feedback that the machine was working well and improved production efficiency. Mr. Yin is preparing to continue purchasing the centerless grinder from Xieli Machinery to expand the company's production capacity.

The following is Mr. Yin's feedback picture

Centerless grinding machines are mainly used in the Indonesian market for grinding iron pipes with steps, in fields such as mechanical manufacturing, automotive manufacturing, furniture manufacturing, and the construction industry.

In the field of mechanical manufacturing, centerless grinders are commonly used to grind iron pipes with steps for manufacturing various mechanical components, such as bearings, gears, etc. These components require strict precision machining requirements, therefore high-quality iron pipes are needed to ensure product quality.

In the field of automotive manufacturing, centerless grinders are commonly used to grind iron pipes with steps in the manufacturing of automotive components, such as engine components, transmission system components, etc.

In the field of furniture manufacturing, iron pipes are commonly used to make supporting structures or frames for furniture, such as sofas, chairs, etc.

In the construction industry, iron pipes are used in building structures, piping systems, and other aspects.

Therefore, the grinding of iron pipes with steps using centerless grinders is widely used in multiple fields in the Indonesian market, and