Feb . 16, 2025 02:01

Back to list

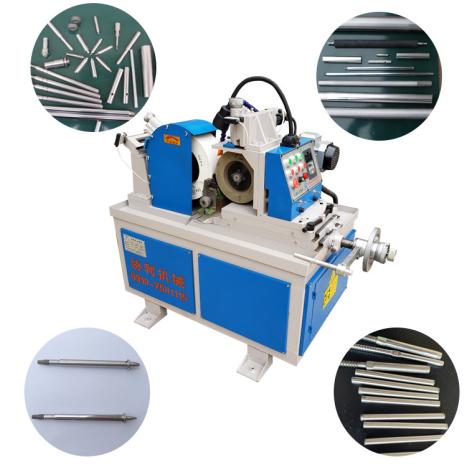

Inner circle polishing machine

Achieving success in the competitive world of manufacturing often requires the use of specialized machinery that can deliver precision, efficiency, and adaptability. One such invaluable machine is the customized centerless grinder, a tool that can enhance production capabilities while maintaining exceptional quality standards. This article delves into the intricacies of customized centerless grinder quotes, emphasizing experience, expertise, authoritativeness, and trustworthiness to empower your decision-making process when enhancing your manufacturing operations.

Factors Influencing Customized Centerless Grinder Quotes When seeking a quote for a customized centerless grinder, several factors will influence the pricing and specifications 1. Complexity of Customization The extent of the modifications required plays a significant role in determining the cost. More elaborate customizations, such as automation integration or state-of-the-art technology, will naturally increase the price. 2. Material and Size Requirements What materials are you working with, and what are the dimensions of the components? These elements can impact the design and structural needs of the grinder. 3. Production Volume The intended scale of production can influence the customization requirements, as higher volume operations may benefit from additional features to improve efficiency. 4. Technological Enhancements Incorporating cutting-edge technology, such as automatic adjustment mechanisms or real-time monitoring systems, can offer superior performance but may affect the overall investment. Expertise and Authority in the Field Selecting the right supplier for customized centerless grinders requires trust in their expertise and track record within the industry. Manufacturers should seek partnerships with suppliers who boast a proven history of delivering high-quality, tailored solutions. An authoritative supplier will not only understand the intricacies of centerless grinding but will also possess the experience to recommend the best possible solutions for specific operational challenges. Trustworthiness Through Time-Tested Solutions Establishing trust in your chosen supplier is crucial for a successful investment. Look for vendors who have evidence of time-tested solutions and positive testimonials from previous clients. A reputable supplier will provide comprehensive support, from initial consultations and assessments through to after-sales service and maintenance, ensuring that your customized centerless grinder continues to operate optimally. In conclusion, the decision to invest in a customized centerless grinder can significantly impact manufacturing efficiency, precision, and overall production quality. By prioritizing experience, expertise, authoritativeness, and trustworthiness, businesses can ensure that they receive accurate, competitive quotes for machinery that aligns perfectly with their specific operational needs. Investing in a tailored solution not only elevates manufacturing capabilities but cements your position as a leader in precision manufacturing.

Factors Influencing Customized Centerless Grinder Quotes When seeking a quote for a customized centerless grinder, several factors will influence the pricing and specifications 1. Complexity of Customization The extent of the modifications required plays a significant role in determining the cost. More elaborate customizations, such as automation integration or state-of-the-art technology, will naturally increase the price. 2. Material and Size Requirements What materials are you working with, and what are the dimensions of the components? These elements can impact the design and structural needs of the grinder. 3. Production Volume The intended scale of production can influence the customization requirements, as higher volume operations may benefit from additional features to improve efficiency. 4. Technological Enhancements Incorporating cutting-edge technology, such as automatic adjustment mechanisms or real-time monitoring systems, can offer superior performance but may affect the overall investment. Expertise and Authority in the Field Selecting the right supplier for customized centerless grinders requires trust in their expertise and track record within the industry. Manufacturers should seek partnerships with suppliers who boast a proven history of delivering high-quality, tailored solutions. An authoritative supplier will not only understand the intricacies of centerless grinding but will also possess the experience to recommend the best possible solutions for specific operational challenges. Trustworthiness Through Time-Tested Solutions Establishing trust in your chosen supplier is crucial for a successful investment. Look for vendors who have evidence of time-tested solutions and positive testimonials from previous clients. A reputable supplier will provide comprehensive support, from initial consultations and assessments through to after-sales service and maintenance, ensuring that your customized centerless grinder continues to operate optimally. In conclusion, the decision to invest in a customized centerless grinder can significantly impact manufacturing efficiency, precision, and overall production quality. By prioritizing experience, expertise, authoritativeness, and trustworthiness, businesses can ensure that they receive accurate, competitive quotes for machinery that aligns perfectly with their specific operational needs. Investing in a tailored solution not only elevates manufacturing capabilities but cements your position as a leader in precision manufacturing.

Latest news

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025

-

Sanworld Steel Tube Polishing Machine - OEM Precision & DurabilityNewsMay.18,2025

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025