The Importance of Industrial Metal Polishing Machines

In the world of manufacturing and metalworking, the finish of a product can often determine its success in the marketplace. One critical process that affects the final appearance and performance of metal products is polishing. Industrial metal polishing machines play a crucial role in this process, enhancing the aesthetic appeal, corrosion resistance, and overall functionality of metal components across various industries.

What is Industrial Metal Polishing?

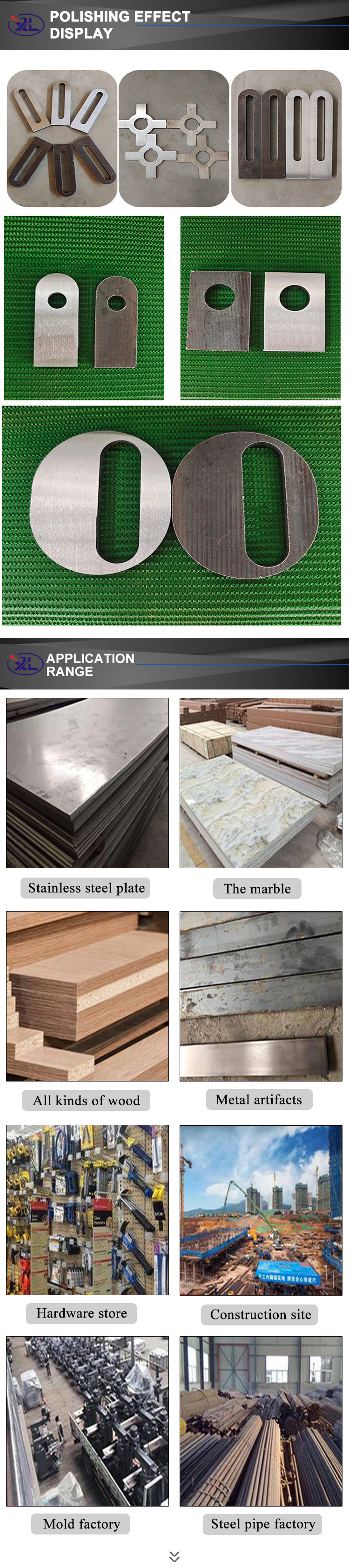

Metal polishing is the process of creating a smooth and shiny surface on metal components. This involves the removal of any imperfections such as scratches, rust, or oxidation. Polishing can also help to prepare a surface for additional treatments, such as plating or painting. While many small-scale operations might utilize manual polishing techniques, industrial applications typically necessitate the use of specialized machines designed for efficiency and quality.

Types of Industrial Metal Polishing Machines

There are several types of industrial metal polishing machines, each tailored for specific applications and metal types. Here are a few common types

1. Belt Polishers Belt polishing machines utilize sanding belts to remove material and create a smooth finish. These machines are highly versatile and can accommodate different belt grits to achieve various finishes.

2. Rotary Polishers Rotary polishing machines use rotating wheels or discs covered with abrasive materials to polish metal surfaces. They are effective for achieving a high-gloss finish on metals like stainless steel and aluminum.

4. Centrifugal Barrel Finishers These machines work on the principle of centrifugal force to accelerate the polishing process. They are particularly useful for small metal parts and provide uniform finishing without damaging critical dimensions.

industrial metal polishing machine

5. Ultrasonic Cleaners Although primarily used for cleaning, ultrasonic cleaning machines can effectively polish delicate components using high-frequency sound waves to agitate cleaning solutions, resulting in a polished finish.

Benefits of Using Metal Polishing Machines

The use of industrial metal polishing machines comes with numerous advantages

1. Efficiency Automated polishing machines significantly reduce the time required to achieve a quality finish compared to manual processes, allowing for higher production rates.

2. Consistency Machines provide uniform results, ensuring that every piece meets the same standards of quality and appearance, which is critical for maintaining brand reputation.

3. Reduction in Labor Costs With machines handling the bulk of the polishing work, labor costs can be reduced. Workers can focus on higher-value tasks rather than time-consuming manual polishing.

4. Enhanced Safety Industrial polishing machines often come with safety features to protect operators and minimize risks associated with manual polishing techniques, such as exposure to dust and sharp edges.

5. Increased Product Life A properly polished surface can help metal components resist oxidation and wear, increasing their lifespan and reducing the need for replacements.

Conclusion

Industrial metal polishing machines are indispensable tools in the metalworking industry. Their ability to efficiently produce high-quality finishes makes them vital for various sectors, including automotive, aerospace, and general manufacturing. As technology advances, we can expect to see even greater innovations in polishing machinery, further enhancing their capabilities and the quality of the final products. Investing in the right polishing equipment is essential for companies looking to improve their production efficiency, product quality, and, ultimately, their competitive edge in the marketplace.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025