Mar . 05, 2025 04:19

Back to list

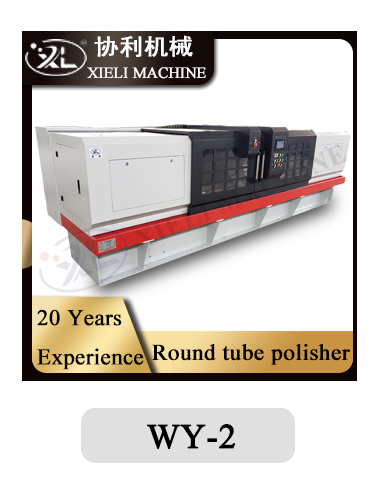

high quality centerless belt grinding polishing machine

In the highly specialized domain of surface finishing technology, SS polishing machines have emerged as indispensable tools revolutionizing the aesthetic and functional aspects of stainless steel products. As industries continue to demand precision and efficiency, understanding the mechanics and benefits of these machines becomes vital for any manufacturer or craftsman working with stainless steel.

Authoritative industry insights reveal a constant innovation trajectory in SS polishing technology. Manufacturers continuously seek to develop machines that are more energy-efficient, environmentally friendly, and capable of handling increasingly intricate designs and materials. The adaptation of sustainable practices, such as the incorporation of recycled abrasives and solvent-free polishing compounds, is becoming more prevalent, aligning industrial objectives with global environmental goals. Choosing the right SS polishing machine depends on various factors, including the scale of operations, the specific requirements of the surface finish, and budget constraints. Expert consultations are advisable to navigate these options, ensuring that the chosen machinery integrates seamlessly with existing production lines and enhances overall operational efficiency. Trust in SS polishing machines is further reinforced by industry standards and certifications, which ensure these machines meet the rigorous demands of quality and safety. Machines that comply with international standards such as ISO 9001 are often preferred, as they guarantee performance reliability and consistent quality outputs. In summation, SS polishing machines represent a cornerstone of modern manufacturing, merging aesthetics with functionality to produce high-quality stainless steel products. As these machines continue to evolve, their implementation within various industries is not just a reflection of technological advancement but a testament to the ongoing pursuit of excellence in product manufacturing. For businesses aiming to maintain a competitive edge, investing in state-of-the-art SS polishing machines is not merely a strategic choice but a necessity dictated by industry dynamics and customer expectations.

Authoritative industry insights reveal a constant innovation trajectory in SS polishing technology. Manufacturers continuously seek to develop machines that are more energy-efficient, environmentally friendly, and capable of handling increasingly intricate designs and materials. The adaptation of sustainable practices, such as the incorporation of recycled abrasives and solvent-free polishing compounds, is becoming more prevalent, aligning industrial objectives with global environmental goals. Choosing the right SS polishing machine depends on various factors, including the scale of operations, the specific requirements of the surface finish, and budget constraints. Expert consultations are advisable to navigate these options, ensuring that the chosen machinery integrates seamlessly with existing production lines and enhances overall operational efficiency. Trust in SS polishing machines is further reinforced by industry standards and certifications, which ensure these machines meet the rigorous demands of quality and safety. Machines that comply with international standards such as ISO 9001 are often preferred, as they guarantee performance reliability and consistent quality outputs. In summation, SS polishing machines represent a cornerstone of modern manufacturing, merging aesthetics with functionality to produce high-quality stainless steel products. As these machines continue to evolve, their implementation within various industries is not just a reflection of technological advancement but a testament to the ongoing pursuit of excellence in product manufacturing. For businesses aiming to maintain a competitive edge, investing in state-of-the-art SS polishing machines is not merely a strategic choice but a necessity dictated by industry dynamics and customer expectations.

Latest news

-

High-Efficiency Automatic Stainless Steel Polishing Machine OEM & WholesaleNewsMay.11,2025

-

Top Pipe Polishing Machine Manufacturers Automated & Stainless Steel SolutionsNewsMay.11,2025

-

Mikrosa CNC Centerless Grinder High Precision, OEM & Discount ModelsNewsMay.10,2025

-

Retrofit Servo Centerless Grinder - OEM Precision & Discount SolutionsNewsMay.10,2025

-

Precision Centerless Grinder Suppliers CNC & Polishing SolutionsNewsMay.10,2025

-

Affordable OEM Centerless Grinders - China-Made & Discounted PricesNewsMay.10,2025