Pipe Polishing Machine Suppliers Elevating Efficiency in Metal Finishing

In today’s competitive manufacturing environment, the demand for high-quality metal finishing has never been more critical. Pipe polishing machines play a vital role in achieving the desired surface finish on pipes and tubes made from various metals. These machines not only enhance the aesthetic appeal of the products but also improve their resistance to corrosion and other forms of damage. As a result, finding reliable pipe polishing machine suppliers becomes paramount for businesses seeking to elevate their production processes.

Understanding Pipe Polishing Machines

Pipe polishing machines are specialized equipment designed to polish and finish metal pipes. They utilize various abrasive materials and techniques to remove imperfections, create a smooth surface, and enhance the overall quality of the pipes. These machines are particularly beneficial for industries such as oil and gas, automotive, aerospace, and construction, where the integrity and appearance of pipes are crucial.

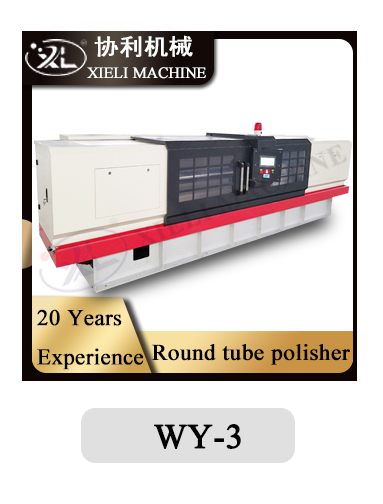

The primary types of pipe polishing machines include belt polishers, roller polishers, and CNC polishing machines, each catering to different requirements and material types. Belt polishers, for instance, are used for continuous surfaces, while roller polishers are ideal for round and tubular shapes. CNC polishing machines offer automation and precision, enabling consistent quality across large production runs.

The Importance of Choosing the Right Supplier

Selecting the right pipe polishing machine supplier can significantly affect the efficiency and quality of the polishing process. A reputable supplier should not only offer high-quality machines but also provide excellent customer support and service. Here are the key factors to consider when evaluating potential suppliers

1. Experience and Expertise Look for suppliers with a proven track record in the industry. Experienced suppliers bring valuable knowledge about machine capabilities and can offer insights into the best products for specific applications.

2. Product Range A wide range of products indicates that the supplier understands the diverse needs of different industries. It’s beneficial to choose a supplier that offers a variety of machine types and configurations to accommodate various materials and project requirements.

pipe polishing machine suppliers product

3. Customization Options Every manufacturing process is unique. Suppliers that offer customization options for their pipe polishing machines enable businesses to tailor the equipment to their specific needs, enhancing efficiency and productivity.

4. Quality Assurance Ensure that the supplier adheres to industry standards and has a quality assurance process in place. This is crucial for ensuring that the machines perform reliably and produce consistent results.

5. After-Sales Service The support provided after the purchase is just as important as the product itself. Suppliers that offer comprehensive after-sales service, including training, maintenance, and spare parts availability, can significantly extend the lifespan of the machines and minimize downtime.

The Future of Pipe Polishing Machines

As technology continues to evolve, we can expect significant advancements in pipe polishing machines. Automation, robotics, and artificial intelligence are beginning to play vital roles in enhancing the capabilities of these machines. Future developments may lead to faster processing times, higher precision, and increased flexibility in handling various materials.

Moreover, as industries become more environmentally conscious, suppliers are increasingly focusing on sustainable practices. This includes developing machines that reduce waste and energy consumption during the polishing process.

Conclusion

In conclusion, the landscape of pipe polishing machine suppliers is critical for businesses aiming to improve their metal finishing processes. By carefully evaluating suppliers based on experience, product range, customization options, quality assurance, and after-sales support, manufacturers can ensure they invest in equipment that enhances efficiency, quality, and productivity. With ongoing advancements in technology, the future of pipe polishing looks promising, offering even more innovative solutions to meet the ever-growing demands of diverse industries. Investing in the right supplier today can pave the way for successful manufacturing tomorrow.

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025

-

Monza 4 Centerless Grinder for Sale High Precision & Discount DealsNewsMay.16,2025

-

Fives Centerless Grinder Precision OEM Solutions & Discount PricingNewsMay.16,2025

-

High-Quality Centerless Grinder Wheels Discounts & China SuppliersNewsMay.15,2025