Exploring Lidköping Centerless Grinder Factories Crafting Precision in Engineering

In the world of precision engineering, the importance of high-quality machinery cannot be overstated. Among the myriad of manufacturing techniques, centerless grinding stands out as a predominant method for shaping and finishing components with unmatched accuracy. Lidköping, a quaint town in Sweden, has earned a reputation for its centerless grinder factories, which have been at the forefront of precision engineering for decades. This article delves into the significance of these factories, their historical context, and their contribution to modern manufacturing.

A Historical Context

Lidköping's relationship with grinding technologies dates back to the early 20th century. Establishing itself as a hub for precision engineering, the town became the home of several notable machine tool manufacturers. Among them, the Lidköping Machine Tools Company (LMT) was pivotal in developing advanced centerless grinding machines. With a legacy of innovation, Lidköping’s factories have consistently evolved to meet the demands of various industries, from automotive to aerospace.

Principles of Centerless Grinding

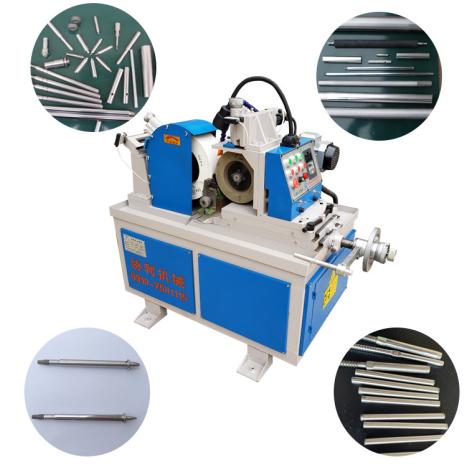

At its core, centerless grinding is a manufacturing process that allows the production of cylindrical parts without the need for a central support. This method employs a configuration where the workpiece is held between two grinding wheels—one for grinding and the other for regulating the speed of rotation. This unique setup allows for exceptional precision, enabling manufacturers to achieve tight tolerances necessary for modern applications.

Lidköping centerless grinders are renowned for their ability to deliver consistent results across large production runs. The machines are designed for ease of operation, minimal downtime, and reduced scrap rates, making them ideal for businesses seeking efficiency and quality.

Advantages of Lidköping Centerless Grinders

1. Precision and Quality The most significant advantage lies in the precision of the end products. Lidköping grinders are engineered to ensure that even the most intricate specifications are met.

2. Versatility These machines can accommodate various materials, including metals, plastics, and composites. This versatility makes Lidköping's offerings suitable for numerous industries.

lidkoping centerless grinder factories

3. Cost-Effectiveness By reducing the need for multiple processes, centerless grinding can cut down on manufacturing costs. The efficiency of these machines translates to better margins for manufacturers.

4. Speed With the capability to handle high-volume production, Lidköping centerless grinders can process large quantities of items in shorter time spans, allowing for quicker turnaround and delivery times.

Industry Applications

Lidköping’s centerless grinders have found applications across a plethora of industries. The automotive sector is a significant user, where components like axles, pins, and bushings require high precision for optimal performance. Similarly, the aerospace industry relies on Lidköping machines to ensure the integrity of thousands of components in flight-critical applications. Other sectors include medical device manufacturing, where precision and quality are non-negotiable, and the energy industry, where turbine and shaft components benefit from the accuracy of centerless grinding.

Innovations and Future Trends

As we venture deeper into the 21st century, Lidköping’s factories are not resting on their laurels. They are engaged in continuous improvement and innovation. Automation and smart technology integration are the future frontiers being explored. These advancements promise not only to enhance efficiency but also to provide real-time data for better decision-making in the manufacturing process.

Moreover, sustainability is becoming a crucial consideration. Lidköping factories are actively looking into eco-friendly practices, from reducing energy consumption in grinding processes to recycling waste materials.

Conclusion

Lidköping centerless grinder factories exemplify a fusion of tradition and innovation in precision engineering. With a rich history and a commitment to quality, these manufacturers are well-positioned to meet the evolving needs of various industries. As they continue to embrace new technologies and sustainable practices, Lidköping remains a beacon of excellence in the field of centerless grinding, ensuring that the wheels of modern manufacturing keep turning with precision and reliability.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025