Jan . 13, 2025 12:30

Back to list

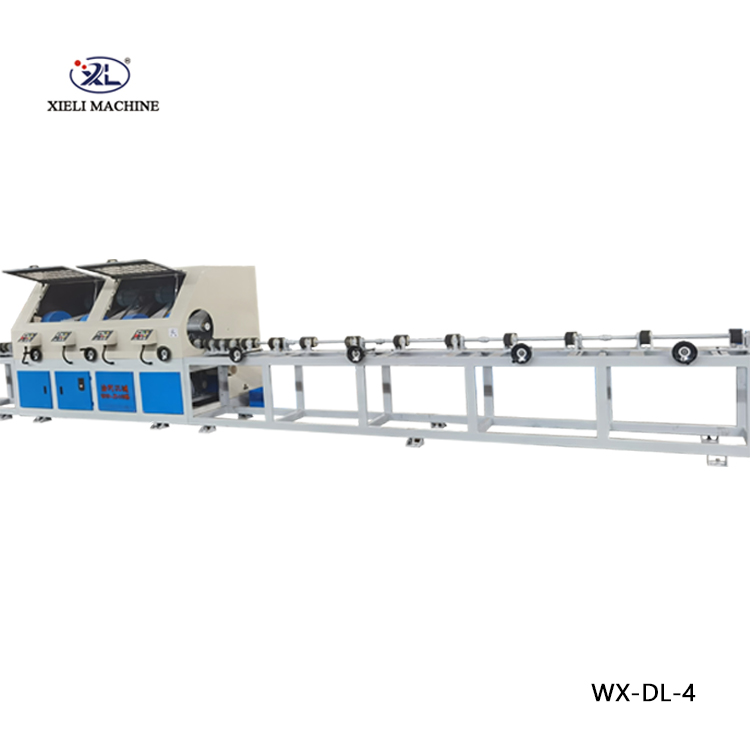

high quality pipe polishing machine

Pipe inside polishing machines have become indispensable tools in various industries, especially for those aiming to achieve high-quality finishes and ensure the superior performance of pipes used in crucial operations. These machines are expertly designed to cater to the meticulous demands of a range of applications, from industrial piping systems to delicate architectural fixtures. This article delves into the intricate world of pipe inside polishing machines, underscoring their engineering marvel, operational excellence, and role in enhancing product longevity.

The authoritative reputation of these machines is not only built on user testimonials but also through rigorous testing and certifications. Reputable manufacturers subject their machines to comprehensive testing phases, often under simulated extreme conditions, to certify their durability and efficacy. These certifications not only reassure potential buyers of the machine's quality but also enhance the compliance profile of companies using them, particularly in regulated industries. In terms of real-world experience, operators consistently report a substantial improvement in both the speed and quality of polishing tasks. These machines have automated many of the labor-intensive aspects of pipe polishing, allowing skilled workers to focus on more complex tasks and thus optimizing human resource allocations. Additionally, machine features such as programmable settings and user-friendly interfaces contribute to a seamless integration into existing workflows. To conclude, pipe inside polishing machines represent a peak of engineering and operational success within their niche. Their adoption across industries attests to their value, delivering not only high-performance outcomes but also a strategic advantage in maintaining the integrity and smooth operation of piping systems. These machines, backed by expertise, authoritativeness, and trustworthiness, embody a critical success factor for companies determined to maintain a competitive edge through superior product quality and efficiency.

The authoritative reputation of these machines is not only built on user testimonials but also through rigorous testing and certifications. Reputable manufacturers subject their machines to comprehensive testing phases, often under simulated extreme conditions, to certify their durability and efficacy. These certifications not only reassure potential buyers of the machine's quality but also enhance the compliance profile of companies using them, particularly in regulated industries. In terms of real-world experience, operators consistently report a substantial improvement in both the speed and quality of polishing tasks. These machines have automated many of the labor-intensive aspects of pipe polishing, allowing skilled workers to focus on more complex tasks and thus optimizing human resource allocations. Additionally, machine features such as programmable settings and user-friendly interfaces contribute to a seamless integration into existing workflows. To conclude, pipe inside polishing machines represent a peak of engineering and operational success within their niche. Their adoption across industries attests to their value, delivering not only high-performance outcomes but also a strategic advantage in maintaining the integrity and smooth operation of piping systems. These machines, backed by expertise, authoritativeness, and trustworthiness, embody a critical success factor for companies determined to maintain a competitive edge through superior product quality and efficiency.

Latest news

-

Surface Grinder & Centerless Grinder Combo OEM, China, Discount DealsNewsMay.23,2025

-

High-Precision Centerless Grinder Machines for Sale China Engine & DiscountsNewsMay.23,2025

-

Cincinnati 2 Centerless Grinder for Sale Precision & Discounted ModelsNewsMay.23,2025

-

Kent Centerless Grinder - High-Precision OEM & Discount ModelsNewsMay.22,2025

-

OSHA Compliant Centerless Grinders Precision & Safety GuaranteedNewsMay.22,2025

-

Precision Tube Polishing Machines Manufacturer Durable & EfficientNewsMay.21,2025