Exploring the Benefits of Engine Centerless Grinder Machines for Sale

When it comes to precision machining, engine centerless grinder machines stand out as a vital tool in the manufacturing industry. These machines are specifically designed to achieve high-accuracy grinding of various components, making them essential for producing parts that meet stringent specifications. In this article, we will delve into what makes centerless grinders so advantageous and why investing in these machines is a sound decision for businesses in need of efficient and reliable grinding solutions.

Centerless grinding is a process that offers several benefits over traditional grinding methods. Unlike conventional grinders, which require a fixture to hold the part in place, centerless grinders utilize a different approach. The workpiece is positioned between two grinding wheels, with one wheel rotating at high speed while the other serves as a regulating wheel that controls the motion and speed of the part. This unique setup allows for continuous grinding, significantly reducing cycle times and increasing productivity.

One of the primary advantages of engine centerless grinder machines is their ability to grind parts without the need for additional setup or fixtures. This flexibility means manufacturers can quickly switch between different components without extensive downtime. As a result, companies that require high-volume production can operate more efficiently, responding swiftly to market demands and minimizing lead times.

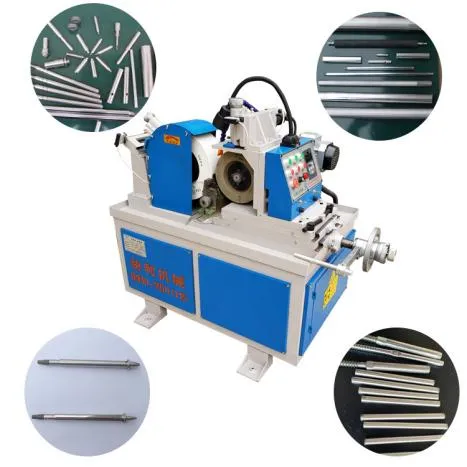

engine centerless grinder machine for sale products

Furthermore, centerless grinders are capable of producing a superior surface finish. The consistent application of pressure from the grinding wheels ensures that the workpiece is uniformly ground, resulting in an exceptional finish that is often crucial for applications within the automotive, aerospace, and medical industries. This level of precision can significantly enhance product quality, allowing companies to uphold their reputations for excellence.

Another notable benefit is the space-saving design of centerless grinders. These machines typically require less floor space compared to traditional grinders, which makes them a practical choice for manufacturers looking to optimize their production areas. The compact design also allows for easier integration into existing manufacturing lines, streamlining the overall workflow.

When searching for engine centerless grinder machines for sale, potential buyers should consider various factors to ensure they are choosing the right equipment for their needs. Key attributes to look for include the size and specifications of the machine, its grinding capacity, and the technology incorporated into its design. Automation features can further enhance efficiency, so exploring options that include these advancements may lead to even greater productivity gains.

In conclusion, investing in engine centerless grinder machines can significantly benefit businesses in the manufacturing sector. With enhanced efficiency, superior surface finish capabilities, and a compact design, these machines are essential for companies aiming to improve their production processes. As the demand for precise and reliable parts continues to grow, the importance of having quality grinding solutions will only increase. Therefore, when considering upgrades or new purchases, engine centerless grinders should be at the forefront of your decision-making process.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025