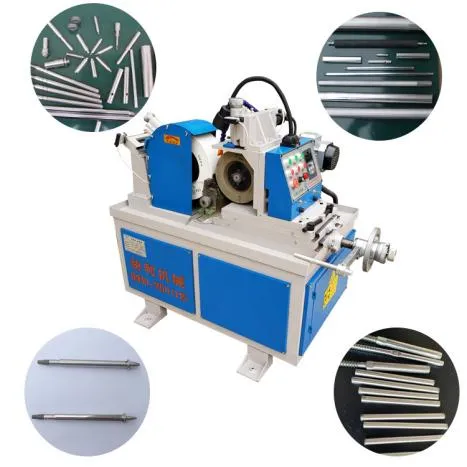

Centerless Belt Grinding and Polishing Machine A Comprehensive Overview

In the realm of manufacturing and metalworking, achieving high precision and a smooth finish on various components is paramount. One of the innovative solutions that has revolutionized these processes is the centerless belt grinding and polishing machine. This technology is designed to enhance both efficiency and quality in the finishing of cylindrical parts, making it a critical tool in many industries.

What is Centerless Grinding?

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods that involve placing the workpiece between two centers, the centerless method supports the workpiece on a work rest blade and utilizes a grinding wheel and a regulating wheel. This configuration allows for continuous operations, where parts can be fed through the machine without the need for manual handling.

The Role of Belt Grinding and Polishing

When integrated with belt grinding technology, centerless machines can achieve fine finishing processes suited for a wide range of materials, including metals, plastics, and composites. Belt grinding utilizes flexible belts instead of traditional grinding wheels, offering superior adaptability and a finer finish. This is particularly advantageous for parts that require a delicate touch and a smooth finish, such as automotive components, aerospace fittings, and precision instruments.

The polishing aspect is equally vital. After the grinding process, a polishing operation can be conducted to achieve an even higher degree of surface quality. This step could involve using different types of belts or compounds designed specifically for polishing, allowing manufacturers to meet various surface finish specifications.

Applications of Centerless Belt Grinding and Polishing Machines

Centerless belt grinding and polishing machines are versatile and find applications across numerous industries

1. Automotive In the automotive sector, these machines are used to process various components, including rods and shafts that require precise dimensions and smooth surface finishes.

centerless belt grinding polishing machine factory

3. Medical Devices In the medical field, centerless grinding is used for crafting instruments and implants that need to adhere to stringent hygiene and precision standards.

4. Tool Manufacturing Toolmakers benefit from the ability to create tools with sharp edges and refined surfaces, thus increasing their efficacy and longevity.

Benefits of Using Centerless Belt Grinding and Polishing Machines

There are several advantages to incorporating centerless belt grinding and polishing machines into production lines

1. Efficiency These machines can process numerous parts simultaneously with minimal downtime, increasing overall productivity.

2. Precision They provide highly accurate dimensions and surface finishes, which are crucial for high-performance applications.

3. Flexibility The adaptable nature of belt grinding allows for the processing of various materials and part geometries, making it suitable for a wide range of applications.

4. Cost-Effectiveness With improved efficiency and reduced labor costs, manufacturers can achieve significant savings while maintaining high-quality outputs.

5. Reduced Heat Generation The use of belts instead of wheels produces less heat, minimizing the risk of thermal distortion and ensuring that part integrity is maintained.

Conclusion

As industries continue to evolve, the demand for advanced manufacturing technologies will only increase. The centerless belt grinding and polishing machine stands out as a pivotal innovation in this landscape. Its ability to provide high precision and a superior finish ensures that manufacturers can meet the demanding requirements of modern production. Whether for automotive, aerospace, or medical applications, this technology signifies a commitment to quality and efficiency that drives the future of manufacturing. Embracing such machinery means not only keeping up with industry standards but also pushing the boundaries of what is possible in metalworking and finishing processes.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025