Centerless Grinder Operator A Key Role in Precision Manufacturing

In the realm of precision manufacturing, the centerless grinder operator plays a pivotal role in ensuring the efficiency and accuracy of machining processes. Using specialized equipment designed to grind workpieces without the need for centers or fixtures, centerless grinders facilitate the production of cylindrical parts with remarkable precision. This article explores the responsibilities, skills, and importance of centerless grinder operators, as well as the role of suppliers in supporting their work.

Centerless Grinder Operator A Key Role in Precision Manufacturing

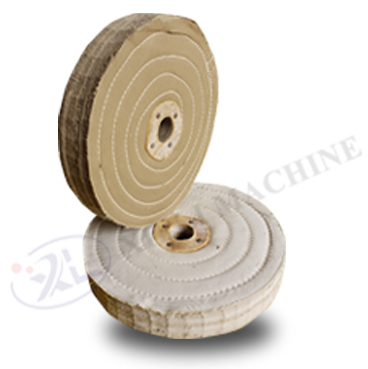

The primary responsibility of a centerless grinder operator is to set up and operate the grinding machinery. This includes selecting the appropriate grinding wheels, adjusting the settings for the type of material being processed, and ensuring that the machine operates within specifications. Operators must have a keen eye for detail, as even the slightest error in setup or operation can lead to defects in the finished product. Additionally, they are responsible for monitoring the grinding process, making real-time adjustments to maintain the desired tolerances.

centerless grinder operator supplier

To excel in this role, a centerless grinder operator should possess a blend of technical skills and practical knowledge. Familiarity with machining principles, mechanical systems, and blueprints is essential. Moreover, operators must be proficient in using measuring instruments, such as calipers and micrometers, to check the dimensions of the ground parts. Continuous training and staying updated with the latest technologies in grinding are crucial for operators to enhance their skills and improve productivity.

Suppliers play a significant role in supporting centerless grinder operators. They provide not only the grinding machines and related equipment but also essential tools, abrasives, and maintenance services. A reliable supplier understands the challenges faced by operators and offers customized solutions to optimize the grinding process. Additionally, they may provide training resources to ensure that operators are well-equipped to handle the machinery effectively.

In summary, the centerless grinder operator is an indispensable part of the precision manufacturing landscape. Their expertise in operating grinding machines ensures the production of high-quality components, meeting the demanding standards of various industries. With the ongoing support from suppliers, operators can continue to refine their skills and adapt to technological advancements, driving innovation and efficiency in manufacturing processes. As industries evolve, the importance of skilled centerless grinder operators will only continue to grow, solidifying their role as key contributors to the success of modern manufacturing.