Through Feed Centerless Grinder Service Enhancing Precision and Efficiency in Manufacturing

In the world of manufacturing, precision and efficiency are paramount. One of the crucial machines that play a significant role in achieving these goals is the through feed centerless grinder. This advanced piece of equipment is essential for producing high-quality cylindrical parts at scale. However, like any machine, it requires regular service and maintenance to perform optimally.

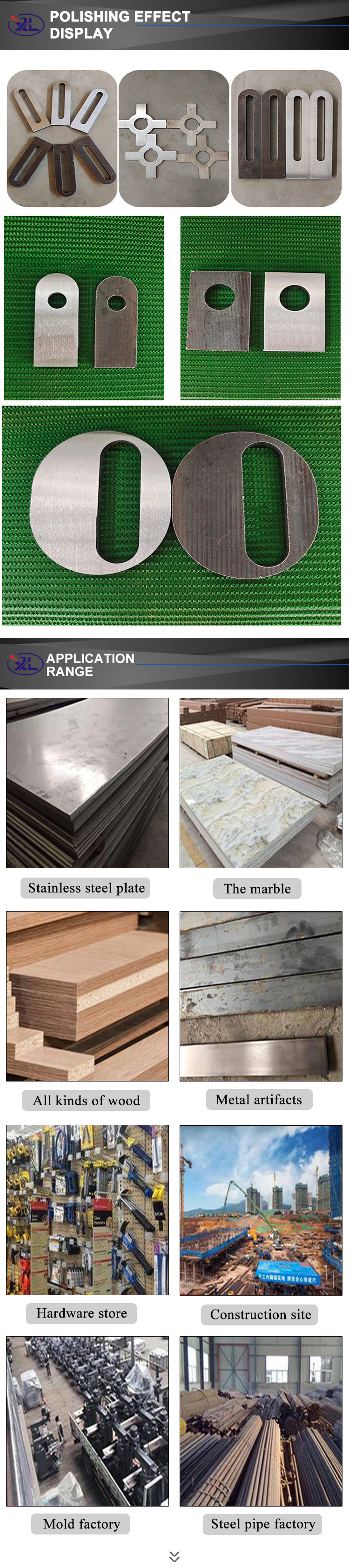

A through feed centerless grinder stands out in its ability to process parts continuously without the need for manual loading and unloading. The machine operates by holding the workpiece between two wheels the grinding wheel and the regulating wheel. This design allows it to grind multiple parts at once while ensuring consistent tolerances and smooth finishes. The effectiveness of this machine, however, heavily relies on proper servicing.

Regular service for a through feed centerless grinder includes several critical aspects. First and foremost is precision alignment. Over time, the components of the grinder may shift due to wear and tear or improper operation. Realigning these parts is essential to maintain accuracy and efficiency in the grinding process. Operators should frequently check the alignment of the grinding and regulating wheels to ensure they are in optimal positions.

through feed centerless grinder service

Another vital part of service involves the maintenance of the grinding wheels themselves. These wheels can wear down or become loaded with material, which can negatively affect performance. Regularly dressing the wheels is necessary to restore their profiles and ensure they cut efficiently. Skilled technicians should perform this task, using specialized tools to achieve the desired shape and surface quality.

Moreover, lubrication is key to optimal grinder function. All moving parts require proper lubrication to reduce friction and wear. A service schedule that includes routine checks and replacements of lubricants helps to prolong the machine's life and keeps it running smoothly. This not only prevents unforeseen breakdowns but also supports the consistent production of high-quality parts.

Lastly, a comprehensive service plan should also include monitoring the operational parameters of the grinder. This includes tracking factors such as spindle speed, feed rate, and coolant flow. Regular analysis of these parameters enables manufacturers to identify potential issues before they escalate, thus minimizing downtime and maximizing productivity.

In conclusion, through feed centerless grinder service is a crucial aspect of maintaining efficiency and precision in manufacturing. By focusing on alignment, wheel maintenance, lubrication, and operational monitoring, manufacturers can ensure their grinding processes remain effective and reliable. Investing in regular service not only extends the life of the equipment but also enhances the overall quality of the manufactured parts, ultimately leading to greater customer satisfaction and success in the competitive marketplace.