Understanding Centerless Belt Grinders and Their Applications

Centerless belt grinders are specialized machines designed for grinding and finishing materials, typically metals, with precision and efficiency. Unlike traditional grinders that may require a fixture to hold the workpiece, centerless grinders utilize a unique setup that allows the workpiece to be supported only by the grinding belt and additional rollers. This innovative design reduces setup time, enhances productivity, and ensures a smoother finish on various materials.

How Centerless Belt Grinders Work

The operational mechanics of a centerless belt grinder are fascinatingly simple yet efficient. The workpiece is placed between a grinding belt and a regulating roller. The grinding belt moves at high speed, providing precision grinding to the material. The regulating roller, positioned at a specific angle, controls the speed of the workpiece, allowing for accurate and consistent grinding. As the belt wears down, it can be easily replaced, ensuring maintenance is straightforward.

This system's key advantage is the absence of a fixed holding fixture. Instead, the workpieces are fed into the grinder from one side and are automatically guided through the grinding process. This streamlined approach results in a continuous operation, which increases the output and efficiency of the grinding process. Whether for simple shaping or intricate finishing, centerless belt grinders offer versatile solutions for different applications.

Benefits of Using Centerless Belt Grinders

1. Efficiency and Speed The continuous feed mechanism of centerless belt grinders means they can handle high volumes of production effectively. Manufacturers looking to maximize throughput find these machines invaluable.

2. Versatility Centerless grinding is not limited to one type of workpiece or material. These grinders can handle various shapes, including round, square, and rectangular pieces, making them suitable for multiple industries, from automotive to aerospace.

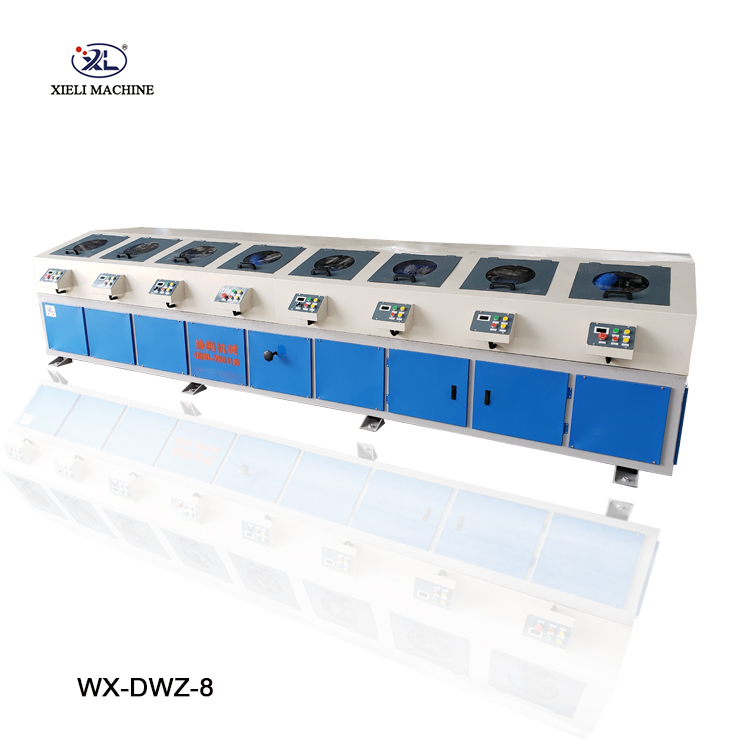

centerless belt grinder products

3. Precision Finishing High-quality surface finishes are essential in many applications. Centerless belt grinders can achieve tight tolerances and exceptional surface finishes, making them ideal for components that require precision engineering.

4. Reduced Setup Time The ability to quickly adjust the machine for different workpieces means less downtime between job changes. This adaptability can significantly increase productivity.

5. Cost-Effectiveness The efficiency and speed of operations can lead to lower manufacturing costs. Additionally, the reduced need for manual handling helps reduce labor costs.

Applications of Centerless Belt Grinders

The adaptability of centerless belt grinders allows them to be utilized across several industries. In the automotive sector, they are often used to grind shafts, rods, and other components to exact specifications. The aerospace industry benefits from the ability of these machines to handle specialized parts that require high precision. Similarly, in the medical field, custom parts for surgical tools and devices can be produced using centerless grinding techniques.

Furthermore, centerless belt grinders are increasingly being used in the manufacturing of precision fasteners and fittings. The ability to create uniform surface finishes and maintain tolerances makes them essential for producing high-quality, reliable components that meet industry standards.

Conclusion

Centerless belt grinders represent a significant advancement in grinding technology. By combining efficiency, versatility, and precision, they have transformed the way various industries approach manufacturing processes. As technology continues to evolve, the innovations surrounding centerless grinding will likely pave the way for even more sophisticated applications and improvements in production efficiency. For manufacturers seeking to enhance their competitive edge, investing in centerless belt grinders is an effective strategy that promises quality and efficiency in their product lines.

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025

-

Sanworld Steel Tube Polishing Machine - OEM Precision & DurabilityNewsMay.18,2025

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025