Centerless Grinding A Key Process for Precision Manufacturing in Cincinnati

In the realm of manufacturing, precision is paramount. Among the various machining processes that emphasize accuracy and efficiency, centerless grinding stands out as a preferred method for producing high-quality cylindrical parts. Cincinnati, a city known for its rich industrial history, is home to several leading suppliers of centerless grinders, who play a significant role in meeting the demands of this precision-driven sector.

What is Centerless Grinding?

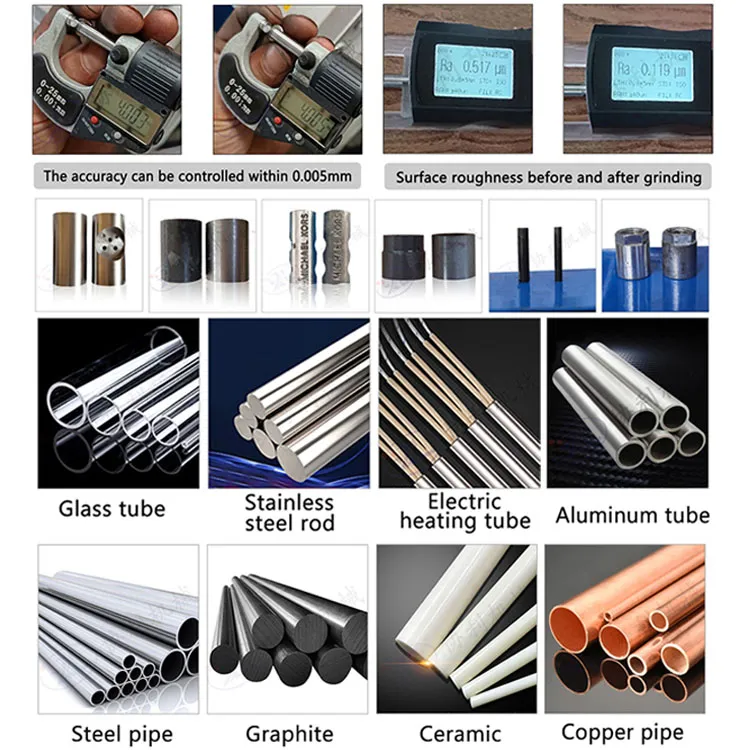

Centerless grinding is a method of removing material from a workpiece by placing it between two rotating grinding wheels. Unlike traditional grinding where the part is mounted on a spindle, centerless grinding allows for continuous production without needing to clamp the workpiece. This method is particularly effective for cylindrical components such as shafts, pins, and rods, which require tight tolerances and smooth finishes.

The process involves three main components the grinding wheel, the regulating wheel, and the workpiece. The grinding wheel performs the actual grinding operation, while the regulating wheel controls the speed and position of the workpiece as it moves through the machine. This unique setup enables manufacturers to achieve high efficiency and precision, making centerless grinding a go-to solution for large-scale production.

The Importance of Centerless Grinders in Manufacturing

Cincinnati is renowned for its manufacturing capabilities, and at the heart of many successful production facilities lies the centerless grinder. These machines provide several advantages, including

1. High Efficiency Centerless grinding significantly reduces cycle times compared to traditional grinding methods. The continuous feeding of workpieces into the grinder allows for high-volume production with minimal downtime.

2. Precision and Consistency With advancements in technology, modern centerless grinders are equipped with sophisticated controls, ensuring that each part meets the required specifications. This level of consistency is crucial for components that will be used in critical applications, such as aerospace, automotive, and medical devices.

3. Versatility Centerless grinders can accommodate various materials, including metals, plastics, and composites. This versatility makes them suitable for a wide range of industries, enabling manufacturers to diversify their product offerings.

cincinnati 2ea centerless grinder suppliers

4. Reduced Setup Time Centerless grinding machines are designed for quick changeovers, allowing manufacturers to switch from one job to another with minimal setup time. This flexibility is essential in today’s fast-paced market where customer demands can change rapidly.

Cincinnati Suppliers of Centerless Grinders

Cincinnati is home to several reputable suppliers of centerless grinders. These companies provide not only the machines themselves but also the support and services necessary to ensure that manufacturers can operate them effectively. Some of the prominent suppliers in the Cincinnati area include

1. Cincinnati Machines A longstanding leader in the industry, Cincinnati Machines offers a wide range of centerless grinding solutions tailored to the specific needs of various industries. Their machines are known for their durability and performance, backed by excellent customer support.

2. Royal Master Grinders Specializing in both traditional and CNC centerless grinding machines, Royal Master Grinders has earned a reputation for innovation and quality. Their commitment to advancing grinding technologies has made them a preferred supplier for high-precision applications.

3. Acme Manufacturing Acme Manufacturing focuses on providing automated solutions for grinding and finishing, including centerless grinding systems. Their advanced technology enables manufacturers to optimize their production processes and enhance overall efficiency.

4. Kuhlman Corporation Kuhlman Corporation supplies a comprehensive range of centerless grinding machines and services. They are dedicated to helping manufacturers achieve their production goals through tailored solutions that emphasize quality and efficiency.

Conclusion

Centerless grinding continues to be a vital process in the manufacturing landscape, especially in precision-focused industries. The suppliers in Cincinnati, with their commitment to quality and innovation, ensure that manufacturers have access to the latest technology and support necessary for success. As the demand for precise and efficient manufacturing grows, centerless grinders will undoubtedly remain integral to the production of high-quality components in Cincinnati and beyond.

-

Stainless Steel Sheet Polishing Machine - OEM, China Factory, Discount DealsNewsMay.31,2025

-

High-Precision Centerless Grinder Machines OEM & Discount OptionsNewsMay.31,2025

-

Precision CNC Centerless Grinder Factory ISO-Certified & Custom SolutionsNewsMay.31,2025

-

High-Precision CNC Centerless Grinding Machine OEM & Discount OptionsNewsMay.30,2025

-

China Stainless Steel Pipe & Handheld Tube Polishing Machine Precision FinishNewsMay.30,2025

-

High-Precision Steel Pipe Internal Grinding Machine OEM & DiscountNewsMay.30,2025