The Evolution and Impact of Automatic Centerless Grinding Machine Factories

In the realm of precision manufacturing, the advent of automatic centerless grinding machines has revolutionized the production landscape. These machines, which operate on the principle of centerless grinding, provide unparalleled efficiency and accuracy for a myriad of applications. This article explores the significance of automatic centerless grinding machine factories, their operational principles, the manufacturing process, and their impact on various industries.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from a workpiece without the need for a central support. This innovative process allows for the continuous feeding of workpieces, making it ideal for high-volume production. Unlike traditional grinding methods, which require complex setups and fixtures, centerless grinding machines simplify operations, reducing the time and labor involved in machining tasks.

At the heart of the centerless grinding operation are three critical components the grinding wheel, the regulating wheel, and the workpiece itself. The grinding wheel performs the primary cutting action, while the regulating wheel controls the speed and feed rate of the workpiece. The absence of supports means that the workpiece is held in place solely by the interaction of these two wheels, allowing for a more efficient and streamlined grinding process.

The Role of Automatic Centerless Grinding Machine Factories

Automatic centerless grinding machine factories have taken the efficiency of this process to the next level. The automation of these machines has led to significant advancements in manufacturing capabilities. Factories equipped with automatic centerless grinding machines can achieve high precision, reduced operational costs, and increased production rates.

Automation in these factories often involves the integration of advanced technologies such as robotics, computer numerical control (CNC), and real-time monitoring systems. Robots can handle the loading and unloading of workpieces, minimizing human error and maximizing throughput. CNC technology allows for precise adjustments to grinding parameters, ensuring consistent output quality. Real-time monitoring provides instant feedback on the machining process, enabling manufacturers to swiftly identify and rectify issues.

Manufacturing Process in Factories

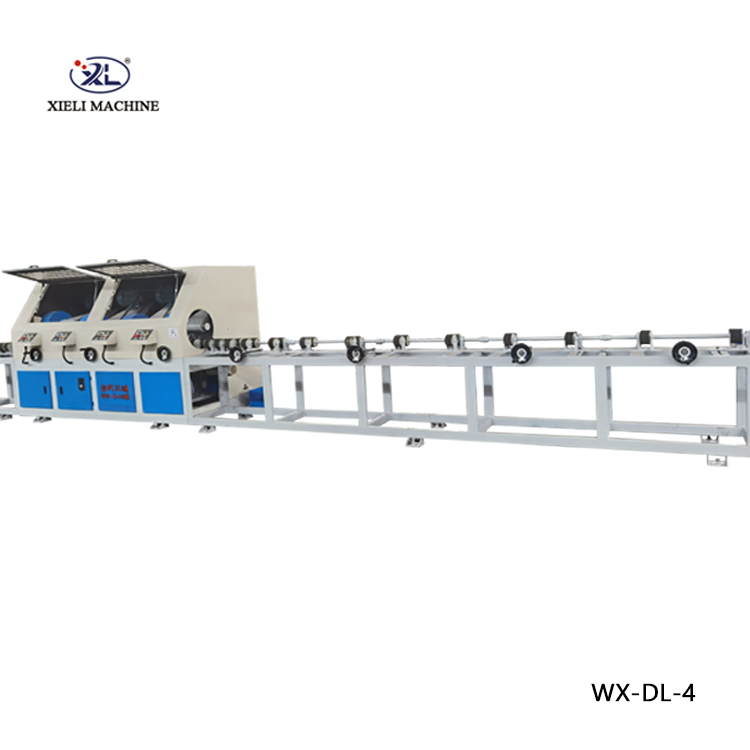

automatic centerless grinding machine factories

The manufacturing process within automatic centerless grinding machine factories typically follows a systematic approach. It begins with the careful selection of raw materials, which are often in the form of bars or tubes. Once the materials are prepared, they are fed into the centerless grinding machines. These machines are pre-programmed with specific parameters to optimize performance based on the type of workpiece being processed.

As the grinding wheels operate, they remove material from the workpieces, achieving desired dimensional specifications and surface finishes. The automatic nature of these machines allows them to function continuously, ensuring high productivity rates. After grinding, workpieces may undergo additional processes such as polishing or coating, depending on the final application.

Impact on Various Industries

The impact of automatic centerless grinding machine factories is profound and wide-ranging. Industries such as automotive, aerospace, medical device manufacturing, and electronics heavily rely on the precision components produced through centerless grinding. For instance, in the automotive sector, centerless grinding is essential for producing components like bearings, bushings, and shafts, all of which require tight tolerances for optimal performance.

In the medical field, the precision offered by centerless grinding is crucial for fabricating surgical instruments and implantable devices. The ability to produce high-quality components in large volumes without compromising accuracy is a game-changer for manufacturers striving to meet stringent industry standards.

Moreover, the operational efficiencies gained through automation contribute to sustainability efforts. By reducing waste and energy consumption, automatic centerless grinding machine factories can operate more environmentally friendly, aligning with the growing demand for sustainable manufacturing practices.

Conclusion

The emergence of automatic centerless grinding machine factories marks a significant milestone in the manufacturing industry. Through advanced automation and precision engineering, these factories enhance productivity and quality while reducing costs. Their impact is felt across various sectors, enabling the production of critical components that drive innovation and growth. As technology continues to evolve, the potential for further advancements in centerless grinding remains promising, paving the way for a new era of manufacturing excellence.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025