Centerless Grinder Company Innovating Precision in Manufacturing

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. One company that has consistently set the benchmark for these qualities is a leading centerless grinder company, renowned for its advanced machining solutions. Centerless grinding, a method that removes material from a workpiece without the need for a fixed setup, allows for high production rates and is ideal for cylindrical parts. This article delves into the core offerings of a typical centerless grinder company, their contribution to the manufacturing sector, and the future of grinding technology.

The Art of Centerless Grinding

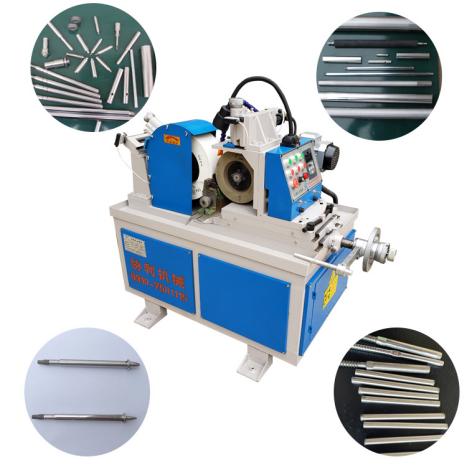

Centerless grinding differentiates itself from traditional grinding methods by eliminating the need for centers or fixtures. This technique involves using a rigid grinding wheel and a regulating wheel to achieve precise diameters and tolerances. The workpiece is supported by the regulating wheel and is fed through the grinding wheel, allowing for continuous operation. This setup not only enhances productivity but also allows for the grinding of multiple parts simultaneously, making it highly efficient for manufacturers.

A reputable centerless grinder company typically offers a wide array of machines tailored to diverse manufacturing needs. These machines range from basic models suited for small-scale operations to highly sophisticated CNC centerless grinders that promise automated control and data integration. The ability to customize equipment according to specific client requirements makes these companies invaluable partners in production.

Technology and Innovation

At the heart of every successful centerless grinder company lies a commitment to innovation. Engineers and technicians in these companies continually strive to enhance both machine performance and user experience. Modern machines are equipped with state-of-the-art controls, enabling operators to monitor and adjust parameters with ease. The integration of automation and robotics has further driven efficiency, reducing labor costs and minimizing human error.

centerless grinder company

Moreover, advancements in grinding wheel technology have led to improved surface finishes and longer tool life. Companies are increasingly investing in research and development to explore new materials and designs that enhance the grinding process. This not only boosts productivity but also aligns with environmental sustainability efforts by reducing waste and energy consumption.

Customer-Centric Approach

Understanding the unique requirements of each client is essential for any leading centerless grinder company. They typically prioritize collaboration, working closely with customers to deliver tailored solutions that meet specific production challenges. This customer-centric approach not only fosters long-term relationships but also ensures that the equipment provided is capable of meeting the client's operational goals.

Training and support services are another critical aspect of their offering. Companies often provide comprehensive training programs for operators and maintenance personnel, ensuring they are well-versed in the functionality and upkeep of the machines. Providing ongoing technical support and service guarantees that customers can maintain peak performance levels throughout the lifespan of the equipment.

The Future of Centerless Grinding

As the manufacturing sector continues to push the boundaries of what is possible, the future of centerless grinding looks promising. Increasing demands for high precision, efficiency, and flexibility are shaping the development of machine tools. The incorporation of Industry 4.0 principles will drive further evolution, integrating artificial intelligence and the Internet of Things (IoT) into grinding operations. This will facilitate real-time monitoring, predictive maintenance, and enhanced data analytics, enabling manufacturers to optimize their processes even further.

In conclusion, a centerless grinder company plays a crucial role in modern manufacturing, providing innovative solutions that meet the growing demands of precision and efficiency. With their focus on technology, customization, and customer support, these companies are not just suppliers but essential partners in the journey toward enhanced manufacturing capabilities. As technology continues to advance, the centerless grinding sector will undoubtedly adapt and thrive, forging new paths in the pursuit of excellence in machining.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025