The Evolution and Importance of Centerless Grinders in Modern Manufacturing

In the ever-evolving world of manufacturing, precision and efficiency are paramount. One of the unsung heroes that enable these qualities is the centerless grinder. Among the various brands and models, the Famous Fives centerless grinder stands out for its innovative design and engineering excellence. This article explores the significance, functionality, and advantages of centerless grinders, with a special focus on the Famous Fives brand.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from a workpiece to create a smooth, cylindrical finish. Unlike traditional grinding methods, where the workpiece is held in place between centers or in a chuck, centerless grinding uses a different approach. The workpiece is positioned between a grinding wheel and a regulating wheel, allowing for continuous rotation and the removal of material along its length. This unique setup facilitates high-speed and efficient grinding, making it a preferred method in various industries.

The Famous Fives Centerless Grinder

The Famous Fives brand has built a solid reputation in the world of centerless grinding, offering machinery that boasts exceptional reliability and performance. Founded in the early 20th century, Famous Fives has consistently pushed the boundaries of engineering and technology. Their centerless grinders are engineered with precision and designed to meet the diverse needs of manufacturers, from automotive to aerospace and beyond.

Famous Fives centerless grinders are known for their robust construction, customizable features, and advanced controls. The machines are designed to accommodate a wide range of workpieces, making them versatile tools in the manufacturing process. Key features often include

1. Precision Engineering Famous Fives grinders offer tight tolerances and high-speed capabilities, ensuring that every part produced meets stringent industrial standards. 2. Customizable Options With a variety of configurations available, manufacturers can tailor the setup of their grinders to suit specific applications and workpiece geometries.

3. User-Friendly Controls Advanced digital controls enhance the user experience, allowing operators to monitor and adjust parameters with ease for optimal grinding performance.

4. Sustainability Features Many modern machines are designed with energy efficiency in mind, reducing waste and minimizing environmental impact.

Advantages of Centerless Grinding

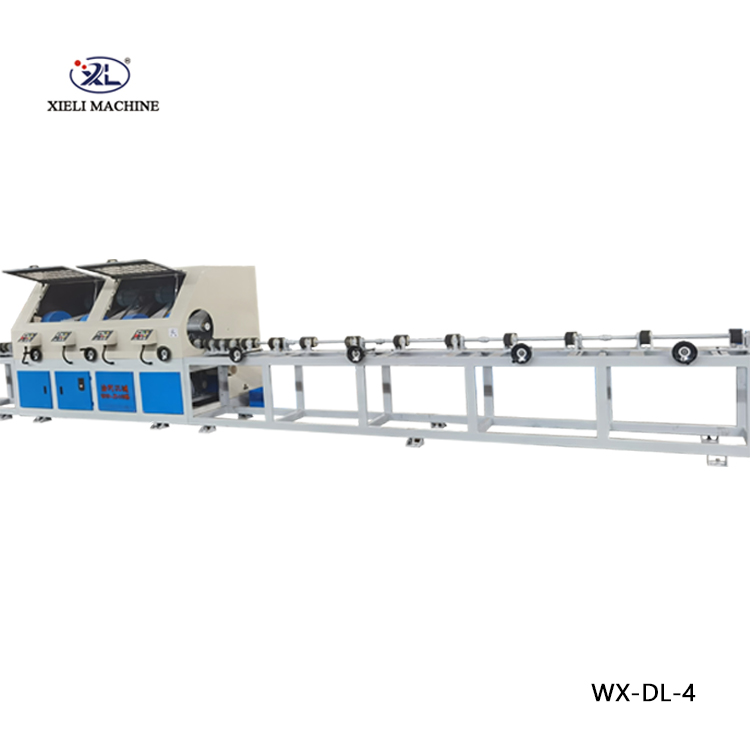

famous fives centerless grinder

The benefits of centerless grinding are numerous. Here are some key advantages that make this process indispensable in production environments

2. Reduced Setup Time The simple setup involved in centerless grinding allows for quicker changeovers between different workpieces, minimizing downtime during production.

3. Elimination of Center Marks Since the workpiece does not need to be centered or chucked, the risk of damaging or marking the part is greatly reduced, ensuring a high-quality finish.

4. Flexibility in Material Types Centerless grinding can be used on various materials, from metals to plastics, which makes it suitable for numerous industries.

5. Consistency and Reproducibility The automated nature of centerless grinding ensures a consistent quality in the output, with minimal variation between parts.

Industries Benefiting from Centerless Grinding

Various industries benefit from centerless grinding technology. Automotive manufacturers use it for producing precision components such as crankshafts and fuel injectors, while the aerospace sector relies on it for critical engine parts and other precision elements. Additionally, medical device manufacturers utilize centerless grinding for the production of surgical tools and implants, where precision is non-negotiable.

Conclusion

The Famous Fives centerless grinder represents a pinnacle of engineering excellence in the realm of manufacturing. Its ability to deliver precision, efficiency, and versatility makes it an invaluable tool across various industries. As manufacturing technology continues to advance, centerless grinding will undoubtedly remain a critical process, contributing significantly to the production of high-quality components. In today’s fast-paced production environment, investing in high-quality machinery like the Famous Fives centerless grinder is essential for manufacturers aiming to stay competitive and efficient.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025