The Importance of OEM Centerless Grinder Machines in Modern Manufacturing

In today’s fast-paced manufacturing environment, precision and efficiency are of paramount importance. One of the tools that have become an essential part of the machining process is the OEM centerless grinder machine. These machines are specifically designed to provide high-precision grinding of cylindrical parts without the need for a guiding fixture, offering several advantages that are critical for modern production.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that differs from traditional cylindrical grinders. Unlike the latter, which requires the part to be held in place between centers or in a chuck, centerless grinders use a different methodology. As the name indicates, the workpiece is placed between two wheels a grinding wheel and a regulating wheel. The regulating wheel controls the axial movement of the workpiece, allowing for a continuous and efficient grinding process.

Advantages of OEM Centerless Grinder Machines

1. High Efficiency One of the main benefits of using OEM centerless grinders is their ability to grind multiple parts simultaneously, significantly increasing throughput. This efficiency is vital for manufacturers that need to produce large volumes of components quickly.

2. Precision and Consistency These machines are designed to achieve tight tolerances and maintain consistency throughout the grinding process. OEM manufacturers ensure that their machines are built with high-quality components, leading to improved accuracy and reduced variation in finished products.

3. Versatility OEM centerless grinders are adaptable to a variety of materials and part sizes. Whether working with metals, plastics, or composite materials, these machines can be set up to handle different shapes and dimensions, making them a versatile choice for manufacturers in different sectors.

4. Reduced Setup Time Thanks to their design, centerless grinders typically require less setup time compared to traditional grinding machines. This allows manufacturers to reduce downtime, increase productivity, and minimize operational costs.

5. Lower Labor Costs The automation capabilities of OEM centerless grinders help reduce the need for manual labor. With advanced features such as in-feed and through-feed capabilities, these machines can operate with minimal supervision, allowing operators to focus on more complex tasks.

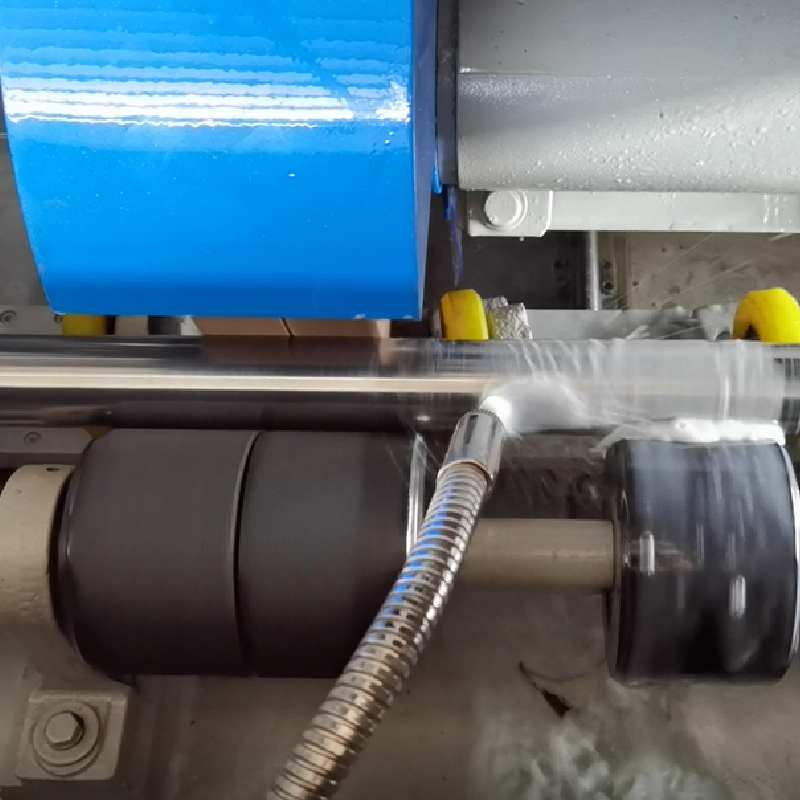

oem centerless grinder machine

Key Components of an OEM Centerless Grinder

The performance of an OEM centerless grinder relies heavily on the quality of its various components. Key features include

- Grinding Wheel This is the primary tool that grinds the workpiece. The selection of the right grinding wheel material and grit size is crucial for achieving the desired finish and dimensional accuracy.

- Regulating Wheel The regulating wheel maintains the workpiece in the correct position and controls the feed rate. Its functionality is essential for the grinding process and impacts the overall efficiency of the machine.

- Dressers These are used to maintain the grinding wheel's shape and surface condition, ensuring optimal performance throughout the grinding cycle.

- Workpiece Support Accurate support for the workpiece is critical in centerless grinding. Advanced systems help in preventing vibration and ensuring stability during the grinding process.

The Future of Centerless Grinding

As technology continues to advance, OEM centerless grinder machines are becoming more sophisticated. Innovations such as digital controls and automated loading systems are emerging, further enhancing the efficiency and precision of the grinding process. Manufacturers today are investing in these machines not only for their operational benefits but also for their ability to adapt to future developments in manufacturing technologies.

In conclusion, OEM centerless grinder machines represent a significant advancement in the field of machining and manufacturing. Their ability to provide efficient, precise, and consistent grinding makes them indispensable tools in the production of cylindrical parts. As industries evolve, the demand for high-quality components produced with minimal waste will increase, underscoring the critical role of centerless grinding technology in meeting these challenges.

-

High Precision Square Rectangle Tube Polishing Machine OEM China DiscountNewsJun.04,2025

-

Premium CNC Centerless Grinder Factory High-Accuracy & Durable MachinesNewsJun.04,2025

-

High Precision CNC Centerless Grinder Machine OEM GrindingNewsJun.04,2025

-

Premium Planetary Pipe Polishing Machine Precision & Efficiency OEM ModelsNewsJun.04,2025

-

DIY Homemade Centerless Grinder – Affordable Precision ToolsNewsJun.04,2025

-

Precision Pipe End Grinding Machine High-Efficiency & Industrial-GradeNewsJun.04,2025