Understanding the Centerless Valve Grinder A Key Tool in Precision Engineering

In the realm of precision engineering, the centerless valve grinder plays an essential role in the manufacturing and maintenance of valves, which are crucial components in various mechanical systems, including engines, pipelines, and industrial machinery. This specialized grinding machine is designed to achieve high precision in the grinding process, ensuring that valves meet strict specifications for performance, durability, and reliability.

What Is a Centerless Valve Grinder?

A centerless valve grinder is a machine used primarily for grinding the surfaces of valves, including their stems and seats, without the need for a supporting fixture. Unlike traditional cylindrical grinders, which require the workpiece to be held in between centers, a centerless grinder operates on a different principle. It uses two circular grinding wheels that operate in concert to grind the valve while it is fed through the machine. This method offers several advantages, including increased efficiency, reduced manufacturing costs, and improved surface finishes.

Key Components of a Centerless Valve Grinder

The centerless valve grinder consists of several critical components that work together to achieve precise grinding

1. Grinding Wheels The primary components of the grinder, the grinding wheels, come in different grits and materials, depending on the specific grinding requirements. These wheels rotate at high speeds and are responsible for removing material from the valve surface.

2. Regulating Wheel Positioned parallel to the grinding wheel, the regulating wheel controls the speed at which the valve is fed through the machine. By adjusting the speed and pressure of the regulating wheel, operators can fine-tune the grinding process for optimal results.

3. Work Rest Blade This component provides support for the valve during the grinding process. It ensures that the valve maintains the correct orientation and position, preventing any wobbling that could lead to inaccuracies.

4. Feed Mechanism This system allows for the continuous movement of the valve through the grinder. It can be manually or automatically controlled, depending on the complexity and volume of the work being performed.

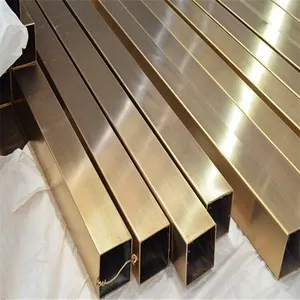

centerless valve grinder

Advantages of Using a Centerless Valve Grinder

The centerless valve grinder offers several advantages over traditional valve grinding methods

- Increased Efficiency The ability to grind valves without the need for fixtures means that multiple pieces can be processed quickly, significantly reducing production times.

- Consistent Precision Centerless grinding provides a high degree of accuracy, ensuring that each valve meets precise specifications. This consistency is vital in applications where valves must fit perfectly within mechanical systems.

- Improved Surface Finishes The grinding action of the machine can produce smoother finishes compared to other methods, enhancing the overall performance and lifespan of the valves.

- Versatility Centerless grinders can handle various valve sizes and shapes, making them suitable for different industries and applications.

Applications in Various Industries

Centerless valve grinders are widely used across a range of industries. In the automotive sector, these machines are essential for producing high-performance engine components that demand strict tolerances. In the aerospace industry, precision-engineered valves are critical for safety and functionality in aircraft systems. Additionally, the oil and gas sector relies on reliable valve performance in pipelines and drilling equipment, making the role of centerless valve grinders indispensable.

Conclusion

The centerless valve grinder is a vital tool in precision engineering, playing a crucial role in producing high-quality valves that ensure the safety and efficiency of mechanical systems. By leveraging its unique grinding capabilities, manufacturers can achieve remarkable precision, efficiency, and versatility in their operations. As industries continue to evolve and demand more from their components, the importance of centerless valve grinders will only grow, solidifying their place as a cornerstone of modern manufacturing technology.

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025

-

Sanworld Steel Tube Polishing Machine - OEM Precision & DurabilityNewsMay.18,2025

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025