Achieving High Quality in Precision Machining through Feed Centerless Grinding

In the realm of precision machining, centerless grinding has emerged as a pinnacle of efficiency and quality. This innovative process, especially when optimized through advanced feed mechanisms, has transformed how industries approach the production of high-quality components. With its ability to handle various materials and achieve tight tolerances, feed centerless grinding stands out as a crucial technology in manufacturing.

Achieving High Quality in Precision Machining through Feed Centerless Grinding

One of the key innovations in centerless grinding is the use of advanced feed mechanisms. A well-designed feed system is vital for controlling the material removal rate and achieving uniform dimensional tolerances. Modern feed systems utilize computer numerical control (CNC) technology to optimize the grinding process. By automating the feed rate and adjusting it dynamically based on real-time measurements, manufacturers can enhance the consistency and quality of the finished products.

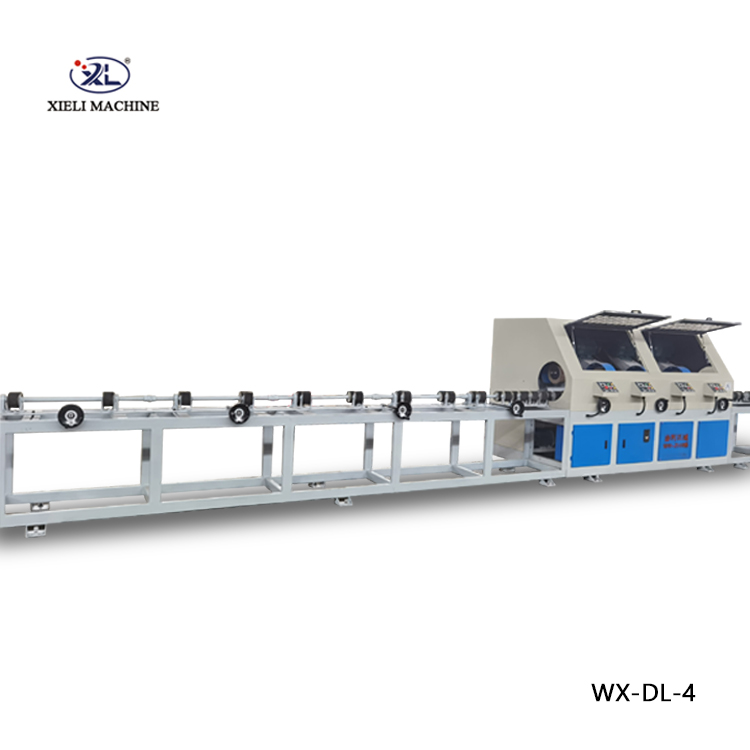

high quality through feed centerless grinder

High-quality outcomes in feed centerless grinding depend on several critical factors. First and foremost is the selection of appropriate grinding wheels. The choice of abrasive material, grit size, and wheel type significantly influences the grinding efficiency and surface finish. For instance, ceramic and diamond wheels are preferred for hard materials, while aluminum oxide wheels are often suitable for softer workpieces. The right wheel not only ensures effective material removal but also contributes to a smoother surface, reducing the need for additional finishing processes.

Moreover, the alignment and setup of the centerless grinder play a pivotal role in achieving high-quality results. Proper alignment of the grinding and regulating wheels is essential for optimal contact with the workpiece. Misalignment can lead to uneven grinding, increased wear on the wheels, and ultimately, compromised part quality. Regular maintenance and calibration of machinery are imperative to sustain high performance and achieve the desired results consistently.

Another aspect of quality in centerless grinding is the importance of cooling and lubrication. Grinding generates significant heat, which can alter the material properties and cause defects such as warping or burning. Effective coolant systems not only dissipate heat but also help remove debris from the grinding area, ensuring that the grinding process remains efficient and effective. Implementing the right cooling strategies can improve tool life, reduce cycle times, and enhance the overall quality of the machined components.

In conclusion, the journey towards high-quality machining through feed centerless grinding is marked by the synergistic interplay of technology, material selection, and maintenance practices. With advancements in feed systems and CNC technology, manufacturers can achieve unprecedented levels of precision and efficiency. As industries continue to pursue higher quality standards, feed centerless grinding will undoubtedly remain at the forefront, providing a reliable and effective solution for producing high-quality machined components. Embracing this technology not only enhances production capabilities but also ensures that manufacturers meet the evolving demands of the market, solidifying their position as leaders in the field of precision machining.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025