Tube Mirror Polishing Machine Factory Elevating Surface Finishing Quality

In the realm of manufacturing and industrial applications, achieving a superior surface finish is essential for promoting aesthetics, function, and durability. One crucial component of this process is the tube mirror polishing machine, which is designed to enhance the surface quality of metal tubes through advanced polishing techniques. This article will explore the significance of tube mirror polishing machine factories, the technology involved, and the benefits they provide to various industries.

The Importance of Surface Finishing

Surface finishing goes beyond visual appeal; it influences a product's performance, corrosion resistance, and longevity. In industries such as automotive, aerospace, and medical, where precision and quality are paramount, the need for effective polishing solutions is critical. Tube mirror polishing machines play an instrumental role in achieving mirror-like finishes that not only meet but often exceed industry standards.

Overview of Tube Mirror Polishing Machines

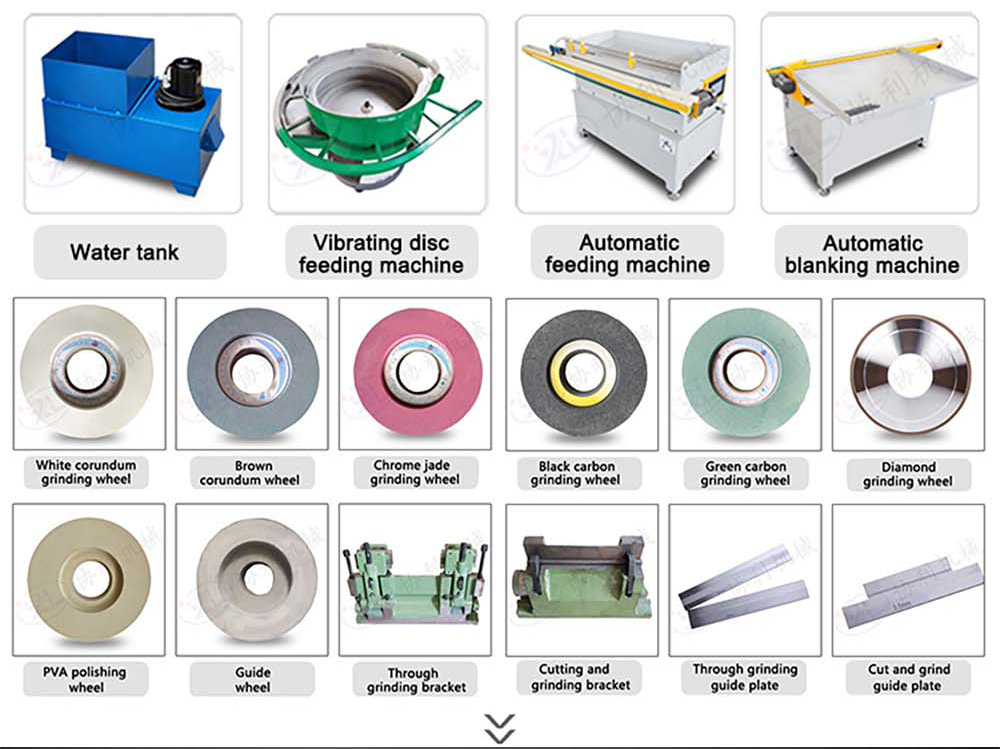

At the heart of any tube mirror polishing machine factory lies cutting-edge technology. These machines operate through a combination of mechanical and chemical polishing processes, ensuring a high-quality finish. The main components include motors, polishing belts or wheels, and a sophisticated control system that allows operators to adjust parameters such as speed, pressure, and duration to cater to various materials and finishing requirements.

Automatic tube mirror polishing machines are particularly noteworthy, as they optimize efficiency and consistency

. These machines can handle multiple tubes simultaneously, significantly reducing production time. Furthermore, with integrated automation systems, manufacturers can achieve precise controls, ensuring that each tube receives uniform treatment.Manufacturing Process in a Tube Mirror Polishing Machine Factory

tube mirror polishing machine factory

In a typical tube mirror polishing machine factory, the manufacturing process begins with the selection of high-quality raw materials. Fabricators employ rigorous quality control measures to guarantee that only the best materials are used in production. Once the materials are ready, skilled technicians assemble the components meticulously, ensuring that each machine meets the factory's stringent standards.

After assembly, machines undergo extensive testing to assess their performance and reliability. Test runs are conducted to evaluate polishing efficiency, surface finish quality, and operational safety. This commitment to quality extends to after-sales service, where manufacturers provide maintenance and support to ensure their machines operate optimally over time.

Advantages of Tube Mirror Polishing Machines

Investing in tube mirror polishing machines offers numerous advantages for manufacturers. Firstly, these machines significantly enhance productivity by streamlining the polishing process. The speed and consistency provided by automated systems enable manufacturers to meet tight delivery deadlines without compromising quality.

Secondly, the capacity to produce high-quality finishes increases the market competitiveness of products. Industries that utilize polished tubes—such as the food and beverage sector, pharmaceuticals, and high-end decorative applications—demand high surface quality, and manufacturers that invest in advanced polishing machines can meet such demands effectively.

Moreover, the longevity of polished tubes enhances end-product durability. A well-polished surface not only resists corrosion but also reduces the likelihood of contaminants sticking, making products safer and more reliable.

Conclusion

In summary, tube mirror polishing machines are indispensable in modern manufacturing, providing industries with the means to achieve impeccable surface finishes. Factories dedicated to this technology play a vital role in enhancing product quality, efficiency, and competitiveness. As industries continue to evolve, the demand for high-performance tube mirror polishing machines is poised to grow, highlighting the importance of these factories in the global manufacturing landscape. Investing in such technology is not merely about fabrication; it is about setting standards for excellence in surface finishing.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025