The Growing Market for Polishing Machines for Stainless Steel Pipes An Overview of Exporters

In recent years, the global market for polishing machines used specifically for stainless steel pipes has witnessed significant growth. This surge can be attributed to the increasing demand for high-quality stainless steel products across various industries, including construction, automotive, oil and gas, and food processing. As the need for precision and durability amplifies, polishing machines play a crucial role in ensuring that stainless steel pipes meet the highest standards of finish and corrosion resistance.

Understanding Polishing Machines

Polishing machines are specialized equipment designed to enhance the surface finish of stainless steel pipes. They remove imperfections, improve aesthetics, and maximize corrosion resistance. Various techniques are employed in the polishing process, including mechanical polishing, electrochemical polishing, and abrasive finishing. Each method has its unique advantages and is chosen based on the specific requirements of the application.

Mechanical Polishing uses abrasive materials to achieve a shiny surface, while electrochemical polishing utilizes an electropolishing process to dissolve a thin layer of material, ultimately providing a smoother finish. Despite their different operational methods, all polishing machines aim to improve the overall quality of stainless steel products, making them essential tools for manufacturers and fabricators.

The Role of Exporters in the Global Market

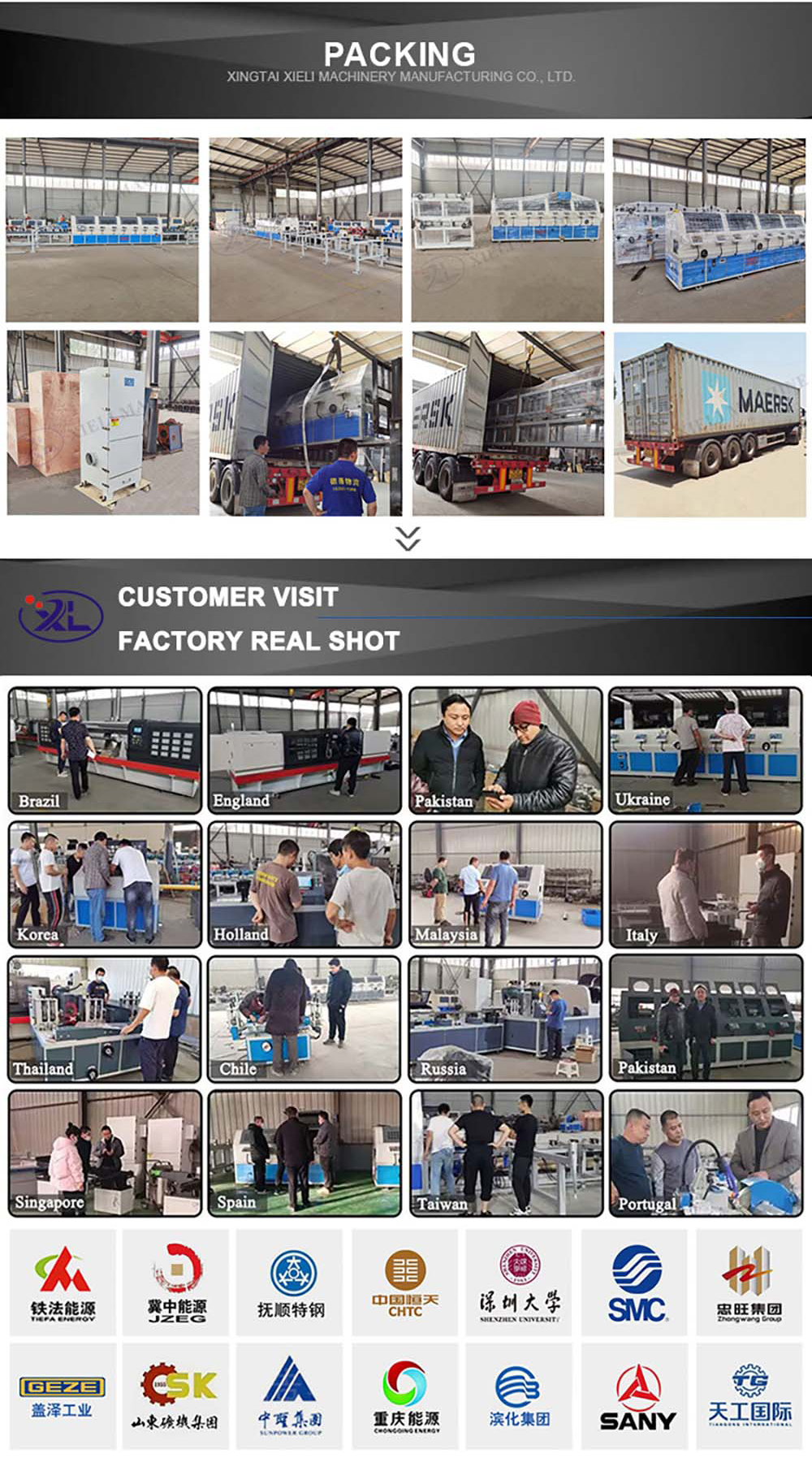

As the demand for high-quality stainless steel pipes continues to rise, so does the need for effective polishing machines. Exporters play a pivotal role in this dynamic market. They connect manufacturers from various regions with suitable machinery that meets global standards. Regions such as Asia, Europe, and North America are significant players in the manufacturing and exporting of polishing machines due to their advanced technological capabilities and established manufacturing infrastructures.

Key Factors Driving the Export Market

1. Global Demand for Stainless Steel The international demand for stainless steel is driven by its ability to withstand harsh environments, making it a preferred material in numerous applications. Consequently, the need for polishing machines is increasing, as manufacturers strive to produce superior-quality stainless steel pipes.

polishing machine for stainless steel pipe exporters

2. Technological Advancements The evolution of polishing technology has boosted efficiency and precision in manufacturing processes. Advanced polishing machines equipped with automation, computer numerical control (CNC), and other innovative features enhance productivity while reducing labor costs, driving their demand among exporters and manufacturers.

3. Growing Industries Sectors such as construction, automotive manufacturing, and food processing are expanding rapidly, leading to a subsequent rise in the demand for stainless steel components. This trend has resulted in a higher requirement for canning and polishing machinery tailored to meet industry specifications.

4. Sustainability and Environmental Regulations Increased awareness of environmental impacts and sustainability has prompted manufacturers to adopt eco-friendly practices. Polishing machines that minimize waste generation and ensure compliance with environmental regulations are now more sought after, enhancing the reputation of exporters who focus on sustainable equipment.

Challenges in the Export Market

Despite the promising outlook, several challenges exist in the polishing machine export market. Fluctuations in the global economy, variations in material costs, and competitive pricing pose significant hurdles for exporters. Additionally, varying international regulations and standards for manufacturing and quality assurance can complicate the export process.

Conclusion

The export market for polishing machines dedicated to stainless steel pipes is poised for continued growth, driven by technological innovations and the surging demand for high-quality stainless steel products. Exporters are crucial in facilitating access to advanced machinery, thereby enabling manufacturers to meet the stringent quality standards required in diverse industries.

As global markets evolve, staying abreast of technological advancements and adapting to changing regulations will remain essential for exporters. By focusing on quality, sustainability, and customer-centric solutions, they can position themselves as leaders in this vibrant and expanding market. The future looks promising for polishing machines, and exporters who can navigate these complexities will undoubtedly thrive in this essential sector of the manufacturing industry.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025