Exploring Pipe Polishing Machines A Guide for Exporters

The demand for high-quality pipe polishing machines has surged in recent years, driven by industries that require pristine finishes on their tubular products. For exporters looking to dive into this niche market, understanding the nuances of pipe polishing machines—from their functionality to market trends—can provide a competitive edge.

What is a Pipe Polishing Machine?

A pipe polishing machine is an industrial equipment designed to polish and finish pipes made from various materials, including stainless steel, carbon steel, and aluminum. These machines can effectively remove imperfections, scratches, and oxidation from the surface of the pipes, resulting in a smooth, shiny finish conducive to both aesthetic appeal and enhanced corrosion resistance.

The machines are used in various sectors, including construction, automotive, aerospace, and manufacturing, where the quality of the pipe's finish can significantly impact performance and durability.

Types of Pipe Polishing Machines

There are several types of pipe polishing machines available on the market, each catering to different needs and specifications

1. Manual Pipe Polishers These are hand-operated machines designed for smaller operations or workshops. They offer flexibility and are typically more affordable, albeit with lower output efficiency.

2. Automatic Pipe Polishers Suitable for large-scale production, these machines are efficient and require minimal human intervention. They often come with advanced features, including programmable logic controllers (PLCs) for precision and consistency.

3. CNC Pipe Polishers Computer Numerical Control (CNC) machines provide the highest level of precision and automation. They can process complex shapes and designs, making them ideal for specialized applications.

4. Belt and Disc Polishers These machines utilize abrasive belts or discs to achieve the desired polish. They are versatile and can handle various pipe diameters.

Factors to Consider When Exporting Pipe Polishing Machines

1. Market Research Understanding the target market's needs is crucial. Different regions may have specific requirements regarding machine standards, safety regulations, and quality certifications.

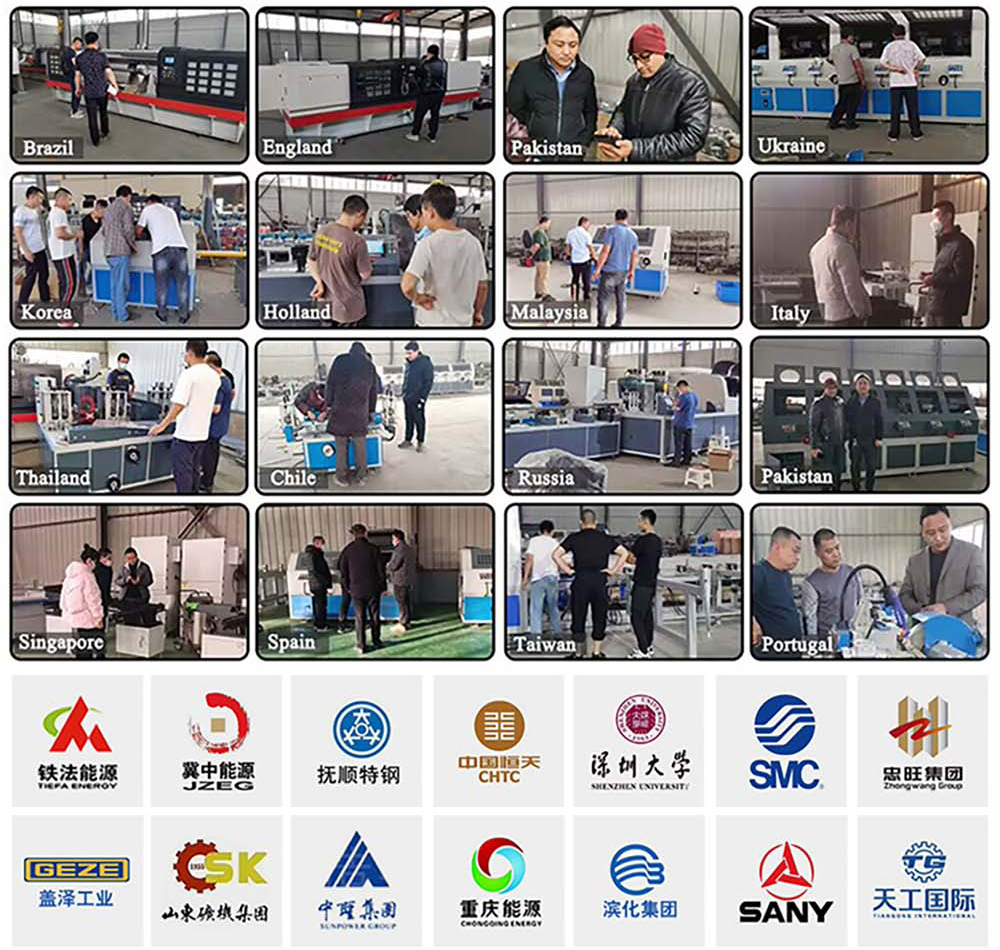

pipe polishing machine for sale exporters

2. Localization Adapting the machines to cater to local preferences and practices can enhance acceptance and integration within local industries. This may include language considerations in machine operation manuals or compliance with local manufacturing standards.

3. Trade Regulations Exporters must be aware of the customs duties, tariffs, and regulations in both the exporting and importing countries. Proper documentation and certifications can facilitate smoother transactions.

4. Logistics and Supply Chain Establishing a reliable supply chain is key to ensuring timely delivery. This includes sourcing quality materials, managing inventories, and selecting shipping methods that ensure the machines arrive in optimal condition.

5. After-Sales Support An excellent after-sales service can set exporters apart from competitors. Providing regular maintenance, spare part availability, and technical support can foster long-lasting customer relationships.

Trends in the Pipe Polishing Machine Market

As technology continues to evolve, several trends are shaping the pipe polishing machine market

1. Automation With the rise of Industry 4.0, more manufacturers are integrating automation into their processes. Pipe polishing machines equipped with IoT capabilities allow for real-time monitoring and predictive maintenance, enhancing efficiency and reducing downtime.

2. Sustainability Eco-friendly practices are becoming essential in manufacturing. Exporters need to consider energy-efficient machines and those that minimize waste during the polishing process.

3. Customization Customers increasingly seek tailored solutions to meet specific operational needs. Providing customizable machines to accommodate various pipe sizes and finishes can attract a broader clientele.

4. Globalization As businesses expand globally, the demand for high-quality pipe polishing machines is growing. Exporters have the opportunity to tap into emerging markets that require advanced manufacturing technologies.

Conclusion

Exporting pipe polishing machines can be a lucrative business venture given the current market trends and industrial demands. By understanding the technical specifications, market needs, and logistical considerations, exporters can effectively position themselves to capitalize on this evolving industry. Investing in innovation and maintaining a customer-oriented approach will undoubtedly yield significant returns in this competitive landscape. As the industry continues to advance, those willing to adapt and grow will emerge as leaders in the global market for pipe polishing solutions.