The Importance of Pipe Buffing Machines in Manufacturing

In today’s competitive manufacturing landscape, maintaining high quality and efficiency is paramount. One crucial piece of equipment that plays a vital role in enhancing the final product's aesthetics and quality is the pipe buffing machine. These machines are specifically designed for polishing metal pipes, improving their finish and preparing them for subsequent processes such as plating or welding.

Understanding Pipe Buffing Machines

A pipe buffing machine is engineered to remove surface imperfections from metal components, particularly pipes and tubes. The process of buffing typically involves using abrasive materials and a rotating wheel to create a smooth and polished surface. The machine operates using a motor that drives the buffing wheel at high speeds, which can achieve various surface finishes depending on the chosen abrasives.

The buffing process not only enhances the visual appeal of the pipes, giving them a shiny and reflective surface but also removes contaminants like dirt, grease, and oxidation. This ensures better adhesion during processes like painting or coating, which can significantly improve the product's durability and longevity.

Key Features of Pipe Buffing Machines

Modern pipe buffing machines come equipped with several advanced features to enhance performance and efficiency

. Some of these include1. Adjustable Speed Settings This feature allows operators to customize the speed of the buffing wheel to suit different materials and finishes, optimizing the process for various applications. 2. Multiple Buffing Heads Many machines are designed with the capability to attach multiple buffing heads, enabling higher productivity as different abrasives can be used for different finishing stages.

3. Variable Pipe Sizes Advanced models are capable of accommodating pipes of varying diameters and lengths, making them versatile tools in a dynamic manufacturing environment.

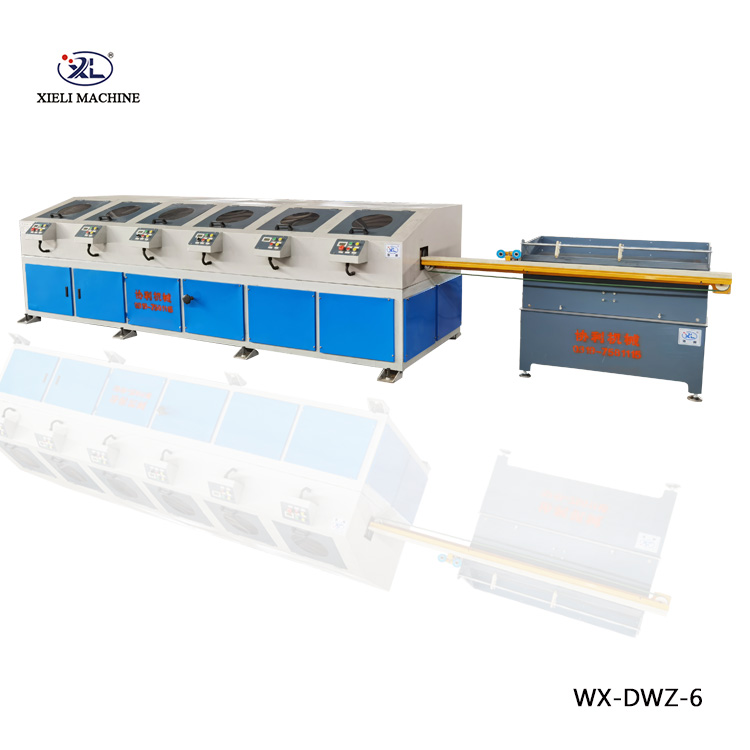

pipe buffing machine

4. Automated Systems Automation features can streamline operations, reducing the need for manual intervention and increasing accuracy. Some machines can even integrate with robotic systems for enhanced efficiency.

5. Dust and Debris Management Effective dust collection systems are integrated into many machines to ensure a clean working environment and protect the health of operators by managing potentially harmful airborne particles during the buffing process.

Applications and Benefits

The applications of pipe buffing machines span various industries, including automotive, aerospace, construction, and plumbing. The polished finish not only improves aesthetics but also contributes to structural integrity. For example, buffs can enhance the flow characteristics of pipes in fluid transportation, reducing turbulence and increasing efficiency.

The environmental benefits are also noteworthy. A well-buffed pipe is less likely to suffer from corrosion, which can lead to leaks and other failures over time. This longevity reduces waste and the need for frequent replacements, contributing to more sustainable manufacturing practices.

Choosing the Right Machine

Selecting the appropriate pipe buffing machine is crucial for manufacturers looking to enhance their production capabilities. Key considerations include the types of materials being processed, the desired finish, production volume, and available floor space. Additionally, it’s essential to assess the machine's compatibility with existing systems and the level of automation required.

Conclusion

In conclusion, pipe buffing machines are indispensable assets in the manufacturing sector. They not only ensure the aesthetic quality of metal pipes but also improve their functional performance. As technology continues to advance, these machines will become even more efficient and versatile, further solidifying their place in the metalworking industry. Investing in the right pipe buffing equipment can yield significant returns, not just in product quality but also in operational efficiency and sustainability. As manufacturers focus on optimizing processes, the role of pipe buffing machines will undoubtedly remain significant.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025