Understanding the Pricing of Famous Centerless Grinders

Centerless grinders are essential machines used in various manufacturing industries for precision grinding of round workpieces without the need for centering fixtures. Their ability to process multiple parts simultaneously while providing high accuracy has made them indispensable tools in modern machining. The price of centerless grinders can vary significantly based on various factors, including brand reputation, technological features, and the specific needs of the user. This article delves into the pricing landscape of centerless grinders, focusing on renowned brands and models.

The Price Range of Centerless Grinders

The price of centerless grinders can range from a few thousand dollars for basic models to over $100,000 for advanced, high-capacity machines. Generally, entry-level centerless grinders designed for smaller, low-volume operations can be found for around $10,000 to $25,000. In contrast, mid-range models with more advanced capabilities typically fall between $25,000 and $75,000. High-end grinders, especially those designed for heavy industrial applications, can exceed $100,000 or even reach upwards of $200,000 when custom features and technologies are included.

Factors Influencing Pricing

Several factors influence the price of centerless grinders

1. Brand Reputation Renowned manufacturers like Glebar, Cincinnati, and Koyo often command higher prices due to their established reputations for quality, durability, and precision engineering. Their machines are trusted in the industry, and the reliability associated with these brands justifies the higher investment.

2. Technology and Features Modern centerless grinders come equipped with various advanced technologies, such as CNC (Computer Numerical Control) capabilities, which allow for more complex operations and precision. Machines with additional features, such as automatic loading systems, enhanced monitoring, and in-machine gauging, also tend to be more expensive.

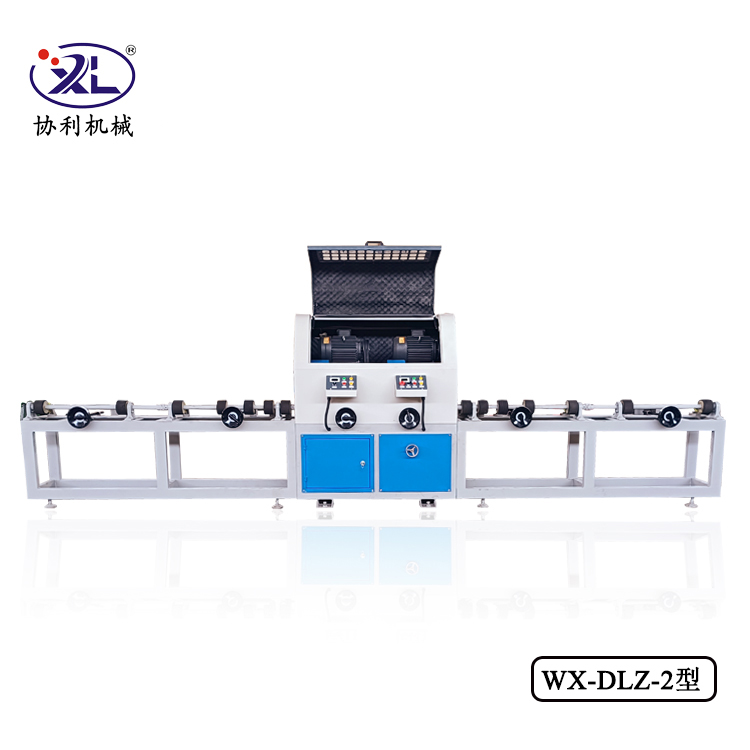

famous centerless grinder price

3. Specifications The size and specifications of the grinder can greatly affect its price. Larger machines with higher grinding capacities and those designed to handle specific materials or complex geometries will generally be priced higher.

4. Application Needs The intended application can also influence the price. For example, grinders used in high-production environments or critical applications such as aerospace components often require higher precision and durability, leading to increased costs.

5. After-Sales Support and Maintenance The availability and quality of after-sales support can impact the total cost of ownership. Brands that offer comprehensive service packages, warranty options, and readily available spare parts may cost more upfront but can provide long-term savings.

Buying New vs. Used

While purchasing a new machine offers the latest technology and warranty support, many manufacturers also consider buying used centerless grinders to save money. The prices for used machines can be significantly lower, ranging from 30% to 70% of the original new price, depending on the condition, model year, and features of the grinder.

However, buyers should be cautious and conduct thorough inspections and assessments before purchasing used equipment. Considerations should include the machine’s maintenance history, any existing wear, and compatibility with current production needs.

Conclusion

When it comes to investing in a centerless grinder, understanding the price landscape is crucial. With costs varying widely based on brand, technology, specifications, and application needs, potential buyers should carefully evaluate their options and align their purchases with their operational requirements. Whether opting for a new or used machine, thorough research and consideration can lead to a wise investment that enhances production efficiency and maintains high-quality standards. Ultimately, the right centerless grinder can serve as a significant asset, driving productivity and profitability in any manufacturing operation.