The Best Internal Centerless Grinding Machine A Comprehensive Overview

In the realm of precision manufacturing, the internal centerless grinding process has emerged as a cornerstone for achieving optimal dimensional accuracy and surface finish. Among the various machinery options available, selecting the best internal centerless grinding machine is crucial for any manufacturing plant that aims to enhance productivity and maintain quality standards. In this article, we will explore the key features, benefits, and considerations in choosing the finest internal centerless grinding machine.

Understanding Internal Centerless Grinding

Internal centerless grinding is a method used to grind the interior surfaces of cylindrical components, such as tubes, rings, and hollow shafts. The key advantage of this technique lies in its ability to produce high-precision internal geometries without the need for complex setups or fixtures. The machine operates on the principle of rotating the workpiece between two grinding wheels the grinding wheel and the regulating wheel. This configuration enables consistent and uniform grinding results.

Features of an Optimal Internal Centerless Grinding Machine

1. Precision Engineering The best internal centerless grinding machines are designed with high-precision components, including rigid frames, advanced spindle bearings, and precision optical measuring systems. This ensures minimal vibration and enhanced stability during operation.

2. Versatility Top-tier machines often feature adjustable grinding angles and variable speeds, allowing operators to accommodate a wide range of workpiece sizes and materials. The ability to grind multiple diameters within a single setup is crucial for maximizing productivity.

3. User-Friendly Controls Modern internal centerless grinders come equipped with intuitive digital control panels. These interfaces allow operators to program grinding operations easily and monitor machine performance in real-time, enhancing overall efficiency.

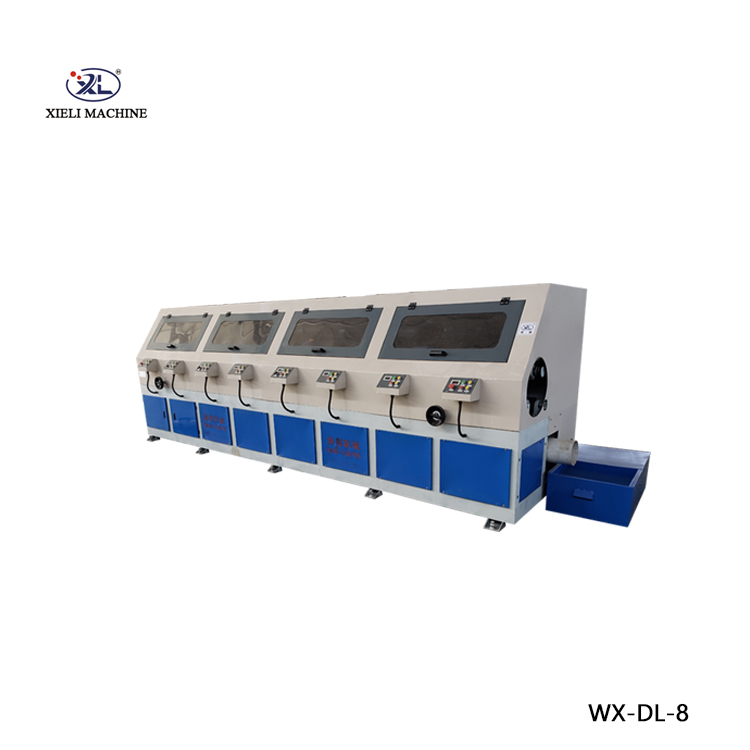

best internal centerless grinding machine

4. State-of-the-Art Cooling Systems Effective cooling mechanisms are vital in centerless grinding to prevent overheating and maintain part integrity. Advanced machines incorporate coolant systems that deliver optimal temperature management, ensuring a quality finish on machined parts.

5. Robust Construction The durability of an internal centerless grinding machine is paramount. Machines constructed from high-quality materials with excellent resistance to wear and tear will provide a better return on investment over time.

Benefits of Using the Best Internal Centerless Grinding Machine

Investing in a premium internal centerless grinding machine translates into numerous advantages for manufacturers. These include

- Enhanced Productivity With faster cycle times and reduced setup periods, companies can increase production rates significantly. - Superior Finish Quality Precision grinding results in finer surface finishes and tighter tolerances, leading to less post-processing and higher customer satisfaction. - Cost Efficiency Though the initial investment may be higher, the operational benefits and reduced wastage contribute to long-term cost savings.

Conclusion

The choice of the best internal centerless grinding machine is a strategic decision that can significantly impact a manufacturing organization's efficiency and product quality. By focusing on precision, versatility, user-friendly controls, effective cooling, and robust construction, manufacturers can ensure they are equipped with a machine that meets their production needs. As the industry continues to evolve, staying informed about advancements in grinding technology will empower manufacturers to make informed choices, driving their success in a competitive landscape.