CE Certification for Steel Pipe Internal Grinding Machines

In the field of manufacturing and industrial equipment, ensuring machinery meets safety and quality standards is paramount. One essential aspect of this is the CE certification, especially for specialized machinery like steel pipe internal grinding machines. This article explores the significance of CE certification for these machines, their operational mechanisms, and the benefits they offer to manufacturers.

CE certification, which stands for Conformité Européenne, is a mark that indicates conformity with health, safety, and environmental protection standards within the European Economic Area (EEA). For steel pipe internal grinding machines, achieving CE certification is crucial as it demonstrates that the equipment complies with European Union regulations, thereby ensuring safe operation and reducing the risk of accidents in industrial settings.

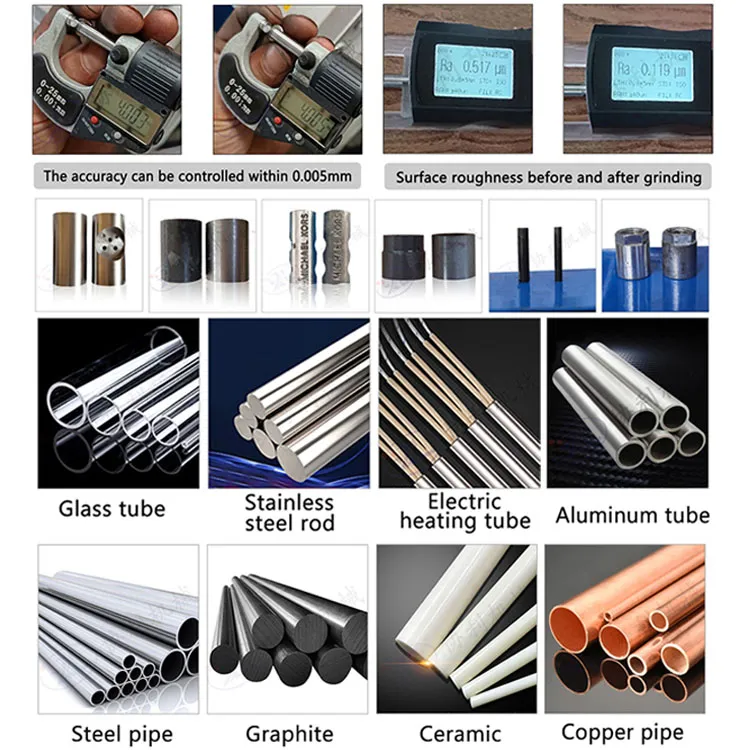

Steel pipe internal grinding machines are designed to enhance the inner surface finish of steel pipes while ensuring precise tolerances. These machines typically utilize advanced grinding technologies and can be equipped with numerical control (NC) systems that allow for high levels of automation and customization. The internal grinding process serves various industries, including construction, automotive, and aerospace, where precision and durability are indispensable.

To achieve CE certification, manufacturers must undergo a comprehensive assessment process. This process involves rigorous testing of the machinery against several directives related to machinery safety, electromagnetic compatibility, and noise emissions, among other criteria. Manufacturers must provide extensive documentation, including design and manufacturing processes, risk assessments, and test results. By adhering to these guidelines, manufacturers demonstrate their commitment to producing high-quality machines that prioritize user safety.

ce certification steel pipe internal grinding machine

The benefits of utilizing CE-certified steel pipe internal grinding machines are multifaceted. First and foremost, these machines ensure the safety of operators and maintenance personnel. By meeting stringent safety standards, the risks of accidents caused by machinery malfunction are significantly minimized. This not only protects employees but also enhances productivity by reducing downtime associated with machine failures.

Additionally, CE certification can enhance a manufacturer’s reputation. Customers seek reliable and safe machinery for their operations, and having CE certification serves as a quality assurance mark. It instills confidence in buyers, fostering trust and encouraging them to invest in such machines. This can ultimately lead to increased sales and a competitive edge in the market.

Moreover, CE certification can open doors to international markets. Many countries require CE certification for imported machinery. Therefore, obtaining this certification can facilitate entry into the European market and beyond, allowing manufacturers to expand their reach and grow their business.

Furthermore, using a CE-certified steel pipe internal grinding machine can result in improved operational efficiency. These machines are often designed with the latest technology, ensuring higher precision and better finish quality. This not only improves product quality but also reduces material wastage, resulting in cost savings for manufacturers.

In conclusion, CE certification is a vital aspect of steel pipe internal grinding machines, reflecting adherence to rigorous safety and quality standards. For manufacturers, achieving this certification not only protects operators but also enhances marketability and scalability in the global market. As industries continue to demand higher precision and safety, the importance of CE-certified machinery will only grow, making it essential for manufacturers to prioritize compliance in their production processes. Embracing these standards not only supports business growth but also contributes to a safer and more efficient industrial landscape.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025