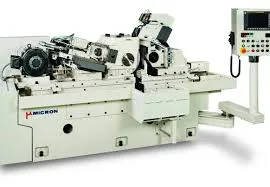

Custom Cylindrical Polishing Machines Innovations and Applications

In the realm of manufacturing and surface finishing, custom cylindrical polishing machines have emerged as crucial equipment for achieving high-quality finishes on cylindrical parts. These machines are designed to enhance productivity, consistency, and precision across various industries, including automotive, aerospace, medical, and general manufacturing.

One of the most significant advantages of custom cylindrical polishing machines is their ability to cater to specific applications. Unlike standard models, custom machines can be designed to meet the unique requirements of different materials, sizes, and shapes of cylindrical components. This level of customization ensures that manufacturers can achieve the desired surface quality, be it gloss, smoothness, or texture, while also optimizing the process for speed and efficiency.

The role of technology in modern custom cylindrical polishing machines cannot be overstated. Many of these machines now incorporate advanced features such as programmable controls, robotic automation, and sophisticated monitoring systems. Programmable controls allow operators to set precise polishing parameters, such as speed, pressure, and abrasive materials, which helps in achieving consistent results across large production runs. Robotic automation further enhances this consistency by removing the potential for human error and increasing throughput rates.

custom cylindrical polishing machine

Another noteworthy trend in custom cylindrical polishing technology is the integration of eco-friendly practices. As industries face increasing pressure to reduce their environmental impact, many manufacturers are developing machines that use less energy and generate less waste. For example, modern polishing machines may employ more efficient pumps and motors, as well as systems designed to recycle polishing compounds and coolants. This not only aligns with sustainable practices but also contributes to cost savings and improved operational efficiency.

The applications of custom cylindrical polishing machines are vast and varied. In the automotive sector, these machines are used to polish components such as shafts, cylinders, and tubes, which require precise surface finishes for optimal performance. In the aerospace industry, where safety and reliability are paramount, polished parts are essential for reducing friction and wear in critical components. The medical field also benefits from custom polishing solutions, ensuring that surgical instruments and implants meet stringent hygiene and quality standards.

Investing in a custom cylindrical polishing machine can also lead to substantial long-term advantages for manufacturers. Over time, the ability to achieve superior surface finishes can result in decreased wear and tear on machinery, leading to lower maintenance costs and extended equipment lifespan. Additionally, products with higher-quality finishes often command better prices in the market, making the investment worthwhile.

In conclusion, custom cylindrical polishing machines represent a vital component of modern manufacturing, characterized by innovation, precision, and adaptability. As industries continue to evolve and demand higher quality standards, the role of these specialized machines will undoubtedly become more significant. By embracing technological advancements and prioritizing customization, manufacturers can enhance their operational efficiency while meeting the diverse needs of their customers.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025