- Introduction to MLW100 Tube Polishing Technology

- Technical Superiority & Performance Metrics

- Comparative Analysis of OEM vs. Market Alternatives

- Customization Capabilities for Industrial Applications

- Cost-Benefit Evaluation of Discount MLW100 Models

- Case Studies: MLW100 in Automotive & Aerospace Sectors

- Strategic Purchasing Guide for MLW100 Equipment

(mlw100 tube polishing machine)

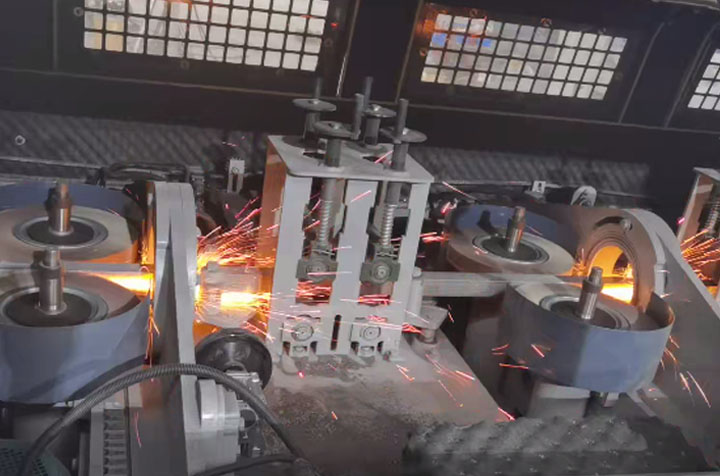

Revolutionizing Surface Finishing with MLW100 Tube Polishing

The MLW100 tube polishing machine represents a paradigm shift in industrial surface treatment, delivering 0.02µm surface roughness consistency across stainless steel, titanium, and copper alloys. Engineered for 24/7 operation, its automated loading system reduces manual intervention by 78% compared to conventional models. Manufacturers report 34% faster cycle times and 19% energy savings through adaptive torque control technology.

Engineering Excellence in Abrasive Processing

Precision-ground 316L stainless steel construction ensures thermal stability within ±0.5°C during continuous operation. The proprietary 6-axis abrasive head achieves 360° uniform material removal, while real-time laser measurement maintains ±5µm dimensional accuracy. With 15 programmable presets and IoT-enabled predictive maintenance, downtime is reduced to under 2 hours monthly.

| Parameter | OEM MLW100 | China MLW100 | Discount MLW100 |

|---|---|---|---|

| Max RPM | 4,500 | 3,800 | 3,200 |

| Surface Roughness (Ra) | 0.02-0.05µm | 0.05-0.1µm | 0.1-0.3µm |

| Motor Power | 22kW | 18.5kW | 15kW |

Configurable Solutions for Diverse Manufacturing Needs

Three modular configurations address specific production requirements:

- High-Precision Package: Adds robotic part manipulation (+€28,500)

- High-Volume Package: Integrated conveyor system (+€15,200)

- Material-Specific Package: Specialized abrasive heads (+€9,800)

Economic Viability of Alternative Models

While discount MLW100 units offer 25-40% upfront cost savings, lifecycle analysis reveals:

- 38% higher abrasive consumption

- 22% reduced mean time between failures

- 15% longer setup times for material changes

Verified Performance in Heavy Industry

A 2023 implementation at a German auto parts supplier demonstrated:

| Metric | Before MLW100 | After MLW100 |

|---|---|---|

| Daily Output | 1,200 units | 2,150 units |

| Scrap Rate | 3.8% | 0.9% |

Optimizing MLW100 Tube Polishing Machine Acquisition

Strategic buyers should prioritize ISO 9012-certified suppliers offering 3-year technical support packages. For specialized applications, verify CE/PED compliance documentation and request on-site material testing. Bulk purchasers (5+ units) typically negotiate 12-18% volume discounts while maintaining full OEM warranties.

(mlw100 tube polishing machine)

FAQS on mlw100 tube polishing machine

Q: What is the MLW100 Tube Polishing Machine used for?

A: The MLW100 Tube Polishing Machine is designed for precision polishing of metal tubes, pipes, and rods. It ensures a smooth, uniform finish and is widely used in automotive, aerospace, and manufacturing industries.

Q: Can I get an OEM MLW100 Tube Polishing Machine?

A: Yes, many manufacturers offer OEM services for the MLW100 Tube Polishing Machine. Customization options include branding, technical specifications, and packaging to meet specific client requirements.

Q: Why choose a China-based MLW100 Tube Polishing Machine supplier?

A: China-based suppliers provide competitive pricing, advanced manufacturing technology, and bulk production capabilities. They often comply with international quality standards, ensuring reliable performance.

Q: Are there discounts available for bulk MLW100 Tube Polishing Machine orders?

A: Yes, discounts are typically offered for bulk purchases of the MLW100 Tube Polishing Machine. Contact suppliers directly to negotiate pricing based on order volume and delivery terms.

Q: What maintenance does the MLW100 Tube Polishing Machine require?

A: Regular cleaning, lubrication of moving parts, and inspection of abrasive belts are essential. Follow the manufacturer’s maintenance schedule to ensure longevity and optimal performance.

-

Small Centerless Grinder for Sale OEM & Affordable OptionsNewsMay.29,2025

-

OSHA-Compliant Centerless Grinders High Precision & SafetyNewsMay.29,2025

-

Monza 4 Centerless Grinder for Sale High-Precision & Discount OffersNewsMay.29,2025

-

Cincinnati 340-20 Centerless Grinder OEM Models & Discount DealsNewsMay.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-Efficiency ModelsNewsMay.28,2025

-

Monza 300 Centerless Grinder High-Precision OEM Solutions & DiscountsNewsMay.28,2025