The Handheld Tube Polishing Machine Revolutionizing Metal Finishing

In the world of metal fabrication, achieving a high-quality finish is paramount. Manufacturers and artisans are always on the lookout for efficient solutions that can streamline operations while delivering superior results. One such solution that has gained traction in recent years is the handheld tube polishing machine. This remarkable device has transformed how metal surfaces are polished, particularly in tubing applications, offering both portability and precision.

What is a Handheld Tube Polishing Machine?

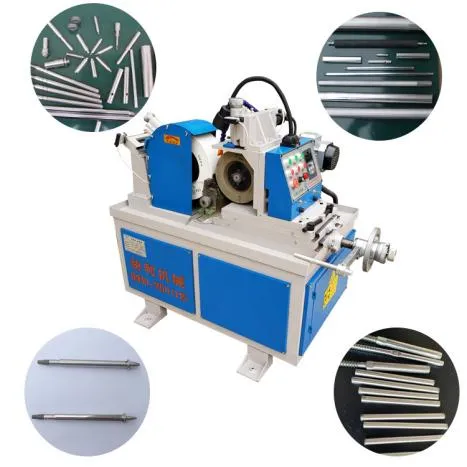

A handheld tube polishing machine is a compact, portable tool designed specifically for polishing metal tubes. It is equipped with various attachments and polishing pads, allowing users to tackle different sizes and shapes of metal tubes. The machine operates using an electric motor, which drives the polishing pad at high speeds, effectively removing imperfections and enhancing the surface finish of the metal.

Key Features

1. Portability One of the standout features of handheld tube polishing machines is their portability. Unlike traditional polishing machines that are often bulky and require dedicated space in a workshop, these handheld devices can easily be transported to different job sites. This feature is particularly beneficial for contractors and professionals who need to polish components in various locations.

2. Ease of Use Most handheld polishing machines are designed with user-friendliness in mind. They often come with ergonomic handles, reducing fatigue during extended use. The machines are relatively lightweight, allowing users to maneuver them with ease, even in tight spaces. This accessibility makes them a favorite among both seasoned professionals and novices in the field.

3. Versatility Handheld tube polishing machines are versatile and can be used on a variety of metal types, including stainless steel, aluminum, and brass. Different polishing pads and compounds can be employed to achieve the desired finish, from a brushed matte look to a mirror-like shine.

hand held tube polishing machine

4. Efficiency Traditional polishing methods can be time-consuming and labor-intensive. Handheld polishing machines significantly reduce the time required to achieve a high-quality finish. With the right technique, operators can polish large quantities of tubing in a fraction of the time it would take using manual methods.

Applications Across Industries

The applications for handheld tube polishing machines span multiple industries. In the automotive sector, these machines are widely used to polish exhaust systems and other metal components, ensuring that they meet both aesthetic and regulatory standards. In the food and beverage industry, maintaining a smooth surface on stainless steel tubing is crucial for hygiene and safety; handheld polishing machines thus play a vital role in equipment maintenance.

Furthermore, the construction industry uses these machines to achieve professional finishes on architectural elements and structural components. The ability to polish both welded and non-welded areas makes these machines indispensable for achieving the desired quality in metalwork.

Conclusion

The handheld tube polishing machine is a powerful tool in the metalworking arsenal, offering efficiency, portability, and versatility. As industries continue to evolve, the demand for high-quality finishes will persist. This machine not only meets that need but also enhances productivity, making it a worthwhile investment for any metal fabrication workshop or contractor.

In essence, whether you’re a craftsman, a manufacturer, or an industrial contractor, the handheld tube polishing machine is an innovative solution that promises to elevate your metal finishing game. As technology continues to advance, these machines will likely become even more refined, pushing the boundaries of what’s possible in metal polishing and finishing. Embracing this equipment could very well be the key to achieving your quality metrics while saving time and labor in your operations.

-

Discount Automatic & Handheld Tube Polishing Machines UK Trusted SupplierNewsMay.07,2025

-

GC500 Centerless Grinder for Sale OEM Precision & Discount Models in ChinaNewsMay.07,2025

-

High-Precision Square/Rectangle Tube Polishing Machine OEM & Discount OptionsNewsMay.07,2025

-

OEM Industrial Metal Polishing Machine High-Efficiency & DurableNewsMay.07,2025

-

Precision Centerless Grinder Machines High Efficiency & Discount DealsNewsMay.07,2025

-

Affordable SS Pipe Polishing Machines Best Prices & QualityNewsMay.07,2025