The Art and Science of Remanufacturing Cincinnati Centerless Grinders

In the highly competitive landscape of manufacturing, precision and efficiency dictate the success of any operation. Among the critical tools that ensure these standards are met is the centerless grinder. Cincinnati centerless grinders, renowned for their accuracy and reliability, have become staples in manufacturing processes across various industries. However, like all machinery, they experience wear and tear over time. This is where the process of remanufacturing comes into play, breathing new life into these essential machines while enhancing their performance and extending their lifespan.

Understanding Remanufacturing

Remanufacturing is a comprehensive process that goes beyond mere repair. It involves disassembling the entire machine, cleaning and inspecting all components, and then replacing or refurbishing parts as needed. This meticulous attention to detail ensures that the remanufactured machine meets or even exceeds its original specifications. For Cincinnati centerless grinders, this means achieving the same level of precision and operational efficiency that customers expect from new equipment.

One of the primary benefits of remanufacturing Cincinnati centerless grinders is the cost-effectiveness. New machines can be prohibitively expensive, and for many businesses, investing in a remanufactured unit allows them to access high-quality machinery at a fraction of the cost. Furthermore, remanufactured grinders often feature upgraded components and technology, providing enhanced performance that may not have been available in older models.

The Remanufacturing Process

The remanufacturing process for Cincinnati centerless grinders typically begins with a thorough assessment. Skilled technicians evaluate the machine to determine which components need attention. This may include the grinding wheels, motors, bearings, and hydraulic systems, among others. Once the assessment is complete, the disassembly begins. Every part is cataloged and cleaned, with worn or damaged components identified for replacement.

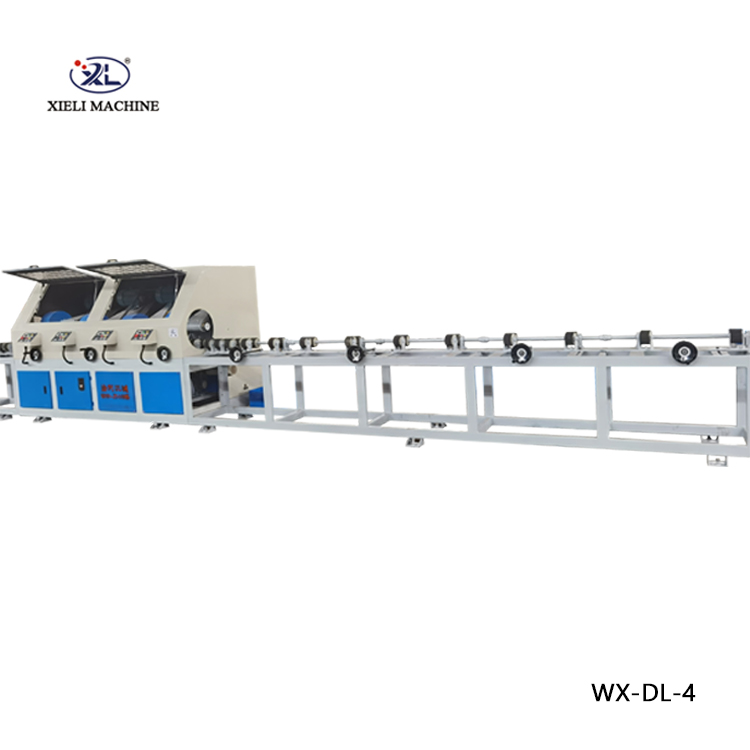

cincinnati centerless grinder remanufacturing product

After the disassembly and cleaning, technicians focus on the rebuilding phase. This is where new parts are installed, and any necessary upgrades are implemented. For instance, incorporating advanced control systems can significantly improve the machine's efficiency and ease of use. The grinding wheels are replaced and aligned to ensure optimal performance, while all electrical systems are inspected and updated as necessary.

Once the remanufactured grinder is fully assembled, it undergoes rigorous testing. This step is crucial in ensuring that the machine performs to the highest standards. Precision measurements and operational tests are conducted to confirm that the grinder meets the necessary tolerances. Only after passing these tests is the remanufactured grinder ready for its new lease on life in a manufacturing environment.

Sustainability and Environmental Impact

In today's world, sustainability is more important than ever. Remanufacturing not only extends the life of existing machines but also reduces waste and minimizes the environmental impact associated with manufacturing new equipment. By choosing remanufactured Cincinnati centerless grinders, companies can significantly reduce their carbon footprint while still obtaining high-performance machinery.

Moreover, remanufacturing contributes to a circular economy by keeping valuable materials in use for as long as possible. This reduces the need for raw material extraction and lowers energy consumption associated with the manufacturing of new machines. In essence, remanufacturing is not just a smart business decision; it's also a step towards a more sustainable future.

Conclusion

In conclusion, the remanufacturing of Cincinnati centerless grinders is a critical service that provides manufacturers with cost-effective, high-quality machinery while promoting sustainability. The process of remanufacturing not only rejuvenates older equipment but also enhances its performance and reliability. As industries continue to evolve, embracing remanufactured solutions will be key to maintaining competitiveness and efficiency in the marketplace. Whether for a small workshop or a large manufacturing facility, remanufactured Cincinnati centerless grinders stand out as a smart investment for the future.

-

High-Precision CNC Centerless Grinding Machine OEM & Discount OptionsNewsMay.12,2025

-

Pipe Belt Grinding Machine High-Precision OEM & Industrial SolutionsNewsMay.12,2025

-

Filmatic Parts for Centerless Grinder Machines OEM & Precision SolutionsNewsMay.12,2025

-

High-Efficiency Automatic Stainless Steel Polishing Machine OEM & WholesaleNewsMay.11,2025

-

Top Pipe Polishing Machine Manufacturers Automated & Stainless Steel SolutionsNewsMay.11,2025

-

Mikrosa CNC Centerless Grinder High Precision, OEM & Discount ModelsNewsMay.10,2025