The Pricing Landscape of Pipe Polishing Machines

In the industrial sector, the demand for high-quality pipe polishing machines has seen significant growth. These machines are crucial for achieving a flawless finish on pipes used in various applications, from plumbing to automotive parts. As the industry evolves, understanding the price dynamics and the key players in the market is essential for businesses looking to invest in these machines.

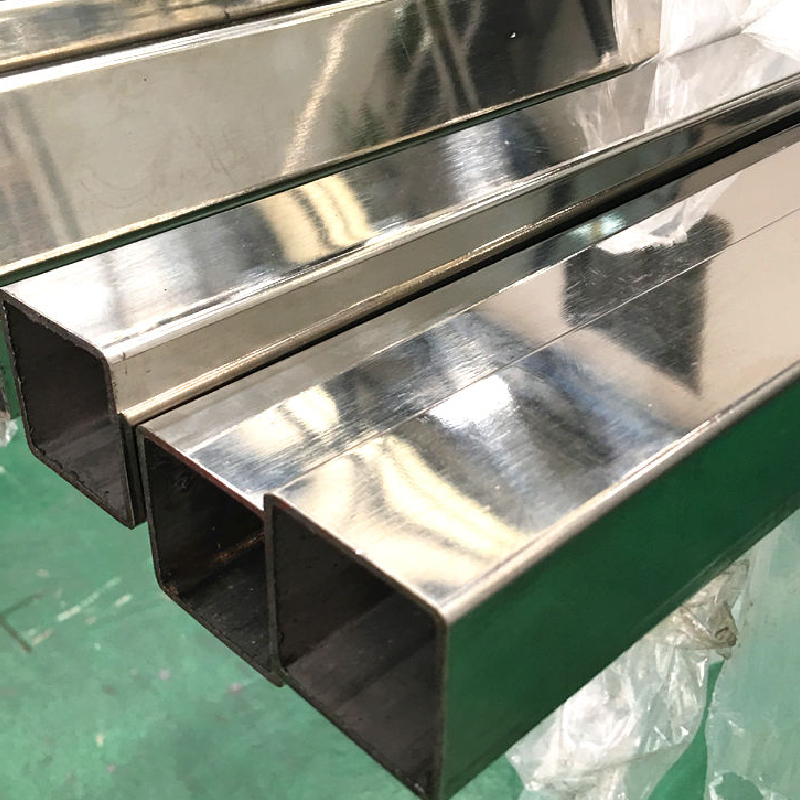

Understanding Pipe Polishing Machines

Pipe polishing machines are engineered to remove imperfections, weld seams, and oxidation from the surface of pipes, producing a smooth and shiny finish. These machines can be classified into several types, including manual, semi-automatic, and fully automated machines. The choice of a particular type depends on the scale of production, the specific requirements of the industry, and budget considerations.

As businesses look to optimize their manufacturing processes, investing in a pipe polishing machine becomes a strategic decision. The right machine can enhance product quality, reduce manual labor, and improve overall efficiency.

Factors Influencing Prices

The price of pipe polishing machines varies significantly based on several factors

1. Type and Features Manual machines tend to be less expensive than automated models. Features such as advanced control systems, high-speed operation, and additional safety mechanisms also impact pricing.

2. Material and Build Quality Machines constructed from high-grade materials, designed for durability and longevity, generally cost more upfront. However, they may offer better value over time due to lower maintenance costs and increased reliability.

3. Brand Reputation Established companies with a track record of quality and service often charge premium prices. However, these brands may provide superior support and a longer warranty, which can justify the investment.

pipe polishing machine price companies

4. Production Capacity Machines designed for high-volume production usually come with a higher price tag. Buyers should assess their production needs to make an informed decision.

5. Technological Advancements Innovations in automation and AI integration can increase the initial investment but lead to significant savings and efficiencies in the long run.

Leading Companies in the Market

Several companies are recognized for manufacturing high-quality pipe polishing machines. They range from small specialized firms to large multinational corporations. Some of the key players include

- Bjöck & Co. Known for its robust machines that cater to various industries, from automotive to construction. - Metabo A leader in power tools, their pipe polishing machines are widely used for their reliability and performance. - Baileigh Industrial They offer a range of machines designed for both small workshops and large manufacturing facilities, focusing on quality and user-friendliness. - KraussMaffei This company is well-known for its high-precision equipment and innovative technology in the polishing sector.

Market Trends and Future Outlook

The market for pipe polishing machines is influenced by several trends, including the increasing demand for aesthetically appealing products and stringent quality standards across industries. The rise of automation in manufacturing processes has also led to greater interest in technologically advanced machines that can enhance production efficiency.

Moreover, the growing manufacturing capabilities in developing countries present opportunities for companies looking to expand their market reach. With advancements in production techniques and materials, manufacturers are likely to innovate further, leading to more cost-effective and efficient solutions for pipe polishing.

Conclusion

Investing in a pipe polishing machine is a crucial step for industries that prioritize quality and efficiency. While the initial cost can vary widely, understanding the factors that influence pricing allows businesses to make informed decisions. As the market continues to evolve, keeping an eye on trends and emerging technologies will be vital for sustaining competitiveness in an increasingly demanding industrial landscape. Whether for small workshops or large manufacturers, the right pipe polishing machine can lead to significant long-term benefits.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025