Polishing Machines for Stainless Steel Pipes A Key Export Product

In the world of manufacturing and metalworking, the demand for high-quality stainless steel pipes is continually rising. These pipes are essential in various industries, including construction, automotive, food processing, and chemical manufacturing. However, the production of stainless steel pipes is not just about cutting and shaping the metal; surface finishing plays a crucial role in enhancing their durability, aesthetic appeal, and resistance to corrosion. This is where polishing machines for stainless steel pipes become vital, especially for exporters looking to meet global standards.

The Importance of Polishing

Polishing is a critical step in the production of stainless steel pipes. It involves the smoothing of the surface to eliminate imperfections, improve appearance, and enhance the protective properties of the material. A well-polished stainless steel surface minimizes the risk of corrosion and contamination, making it ideal for industries that require strict hygiene standards, such as food and pharmaceuticals. Furthermore, polished surfaces are more aesthetically appealing, attracting customers who prioritize both function and form.

The Role of Exporters

Exporters of polishing machines focused on stainless steel pipes are bridging the gap between advanced technology and the global market. These machines are not only essential for manufacturing plants looking to optimize their production processes but also for businesses that aim to export high-quality products. The demand for polished stainless steel pipes varies from region to region, with some markets requiring more refined finishes than others. As such, having access to state-of-the-art polishing machines allows exporters to cater to diverse needs and specifications.

Types of Polishing Machines

polishing machine for stainless steel pipe exporter

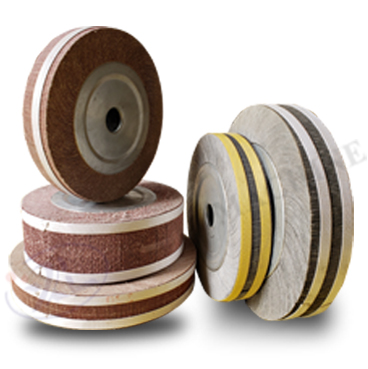

There are various types of polishing machines used for stainless steel pipes, each designed to meet specific requirements. Manual polishing machines provide flexibility and control, making them suitable for small-scale operations or for use on specialized products. Automated polishing machines, on the other hand, enhance efficiency and consistency, making them ideal for large-scale manufacturers. These machines use different techniques, including belt polishing, brush polishing, and electropolishing, to achieve the desired surface finish.

Innovations in Polishing Technology

Recent advancements in polishing technology have greatly improved the efficiency and effectiveness of these machines. For example, the introduction of CNC (Computer Numerical Control) technology allows for precise control over the polishing process, ensuring uniform finishes across batches of pipes. Additionally, innovations such as eco-friendly polishing solutions are becoming more popular as companies strive to reduce their environmental impact while maintaining high production standards.

Challenges and Opportunities for Exporters

Despite the promising market for polishing machines, exporters face several challenges. Competition is fierce, with numerous manufacturers vying for a share of the global market. Additionally, differing regulations and standards across countries can complicate exporting efforts. However, these challenges also present opportunities. By understanding regional markets and investing in high-quality, efficient machines, exporters can establish a strong competitive advantage.

Conclusion

In conclusion, the polishing machine for stainless steel pipe exporters plays an instrumental role in enhancing the quality and appeal of stainless steel products worldwide. As industries continue to evolve and demand increases, the organizations that invest in advanced polishing technologies will be better positioned to succeed in a competitive marketplace. Focusing on quality, efficiency, and environmental sustainability will be key to meeting global demands and achieving long-term success in this essential manufacturing sector.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025