Centerless Grinding An Essential Tool for Precision Engineering

In the world of manufacturing and precision engineering, the importance of effective grinding techniques cannot be overstated. Among these techniques, centerless grinding coupled with surface grinding provides a powerful solution for achieving tight tolerances and superior surface finishes. Consequently, many manufacturers seek out specialized suppliers who can offer high-quality centerless and surface grinding capabilities.

Understanding Centerless Grinding

Centerless grinding is a unique machining process primarily used for shaping cylindrical parts without the use of centers to hold the workpiece in place. This technique operates by using two wheels a grinding wheel and a regulating wheel. The workpiece is positioned between these two wheels, which rotate at different speeds. The grinding wheel removes material from the workpiece, while the regulating wheel controls the rotational speed and the position of the workpiece.

The biggest advantage of centerless grinding lies in its ability to grind multiple parts effectively in a continuous process. This consistency is essential in applications requiring high precision, such as in the production of automotive components, aerospace parts, and medical devices, where tolerances can be incredibly tight.

Surface Grinding A Complementary Process

Surface grinding, on the other hand, is used to create a smooth finish on flat surfaces. It employs a rotating grinding wheel that comes into contact with the workpiece to remove material and achieve the desired flatness and surface finish. This process is vital in industries where flatness is required for proper assembly and function, such as in mold-making and fixture construction.

When combined, centerless grinding and surface grinding can address various manufacturing requirements

. For instance, a provider may use centerless grinding to achieve the desired diameter and cylindrical shape of a part before employing surface grinding to enhance its flatness and surface finish. Utilizing both processes allows manufacturers to optimize production efficiency and meet stringent quality standards.Choosing the Right Suppliers

When looking for suppliers of both centerless and surface grinding, manufacturers should consider several factors

centerless grinder with a surface grinder suppliers

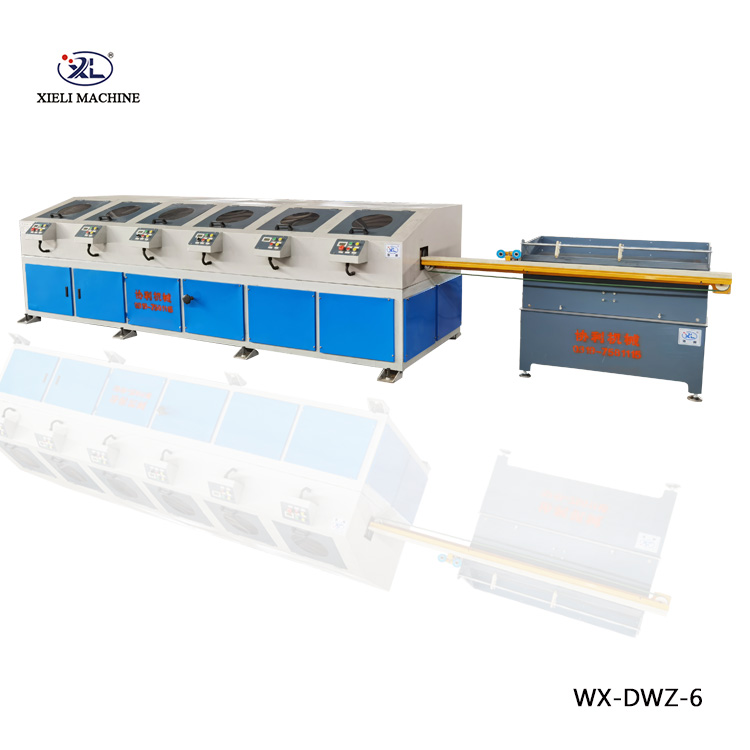

1. Technology and Equipment Ensure that suppliers utilize advanced machinery capable of handling the specific requirements of your projects. Modern CNC (Computer Numerical Control) machines can significantly enhance precision and repeatability.

2. Expertise and Experience The supplier's experience in the industry and familiarity with various materials can play a crucial role in achieving the desired results. Skilled operators are essential for navigating the complexities of different grinding processes.

3. Quality Assurance Look for suppliers who implement rigorous quality control measures to maintain consistent product quality. Certifications such as ISO 9001 reflect a commitment to quality management.

4. Customization Capabilities Every project is unique. Suppliers that can customize their services according to specific requirements often provide greater value. Whether it's adjusting tolerances or accommodating diverse material types, flexibility is key.

5. Lead Times and Capacity Understanding a supplier's production capacity and lead times can help ensure your project timeline is met. Reliable suppliers should deliver on time, without compromising quality.

The Industry Landscape

The demand for centerless and surface grinding services is steadily growing as industries move towards higher precision manufacturing. Automation and advancements in abrasive technology are leading to enhanced capabilities and efficiencies. As competition intensifies, manufacturers are increasingly focusing on finding suppliers who can offer comprehensive grinding solutions while maintaining high standards.

Conclusion

Centerless grinding, when integrated with surface grinding, presents an efficient approach to producing high-quality components in modern manufacturing. By selecting the right suppliers, manufacturers can ensure that they leverage these grinding technologies effectively, ultimately leading to improved product performance and customer satisfaction. As industries evolve, the significance of precision grinding will undoubtedly continue to rise, reinforcing its place as a cornerstone of advanced manufacturing processes.

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025

-

Sanworld Steel Tube Polishing Machine - OEM Precision & DurabilityNewsMay.18,2025

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025