Understanding Centerless Grinder Prices and Suppliers

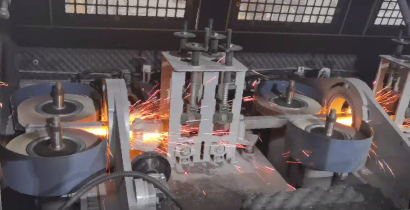

Centerless grinding is a precision machining process that has gained substantial popularity in various manufacturing sectors. It is highly efficient and ideal for producing cylindrical parts that require tight tolerances. Such machines are critical in industries ranging from automotive to aerospace. However, when it comes to purchasing a centerless grinder, one of the primary concerns for manufacturers is understanding the price and selecting the right supplier.

Factors Affecting Centerless Grinder Prices

1. Type of Centerless Grinder There are different types of centerless grinders, including external, internal, and combination types. Each type serves a specific function and varies significantly in terms of complexity and capabilities. For instance, a more advanced model with capabilities for multi-axis grinding will usually cost more than a basic version.

2. Specifications and Features The features of a centerless grinder, such as its capacity, wheel size, and automation level, greatly influence the price. Machines equipped with advanced CNC capabilities can cost significantly more than manual or semi-automated models due to their complexity and the precision they offer.

3. Brand Reputation Well-established brands that have a track record of reliability and quality may charge a premium for their products. However, investing in a reputable brand often translates into better service support, longer lifespan, and higher resale value.

4. Build Quality The materials and engineering behind the machine will directly impact its durability and performance. Machines made from high-quality components may come at a higher initial cost but often prove more economical in the long run due to lower maintenance and higher productivity.

5. Market Trends The demand and supply dynamics also influence pricing. In times of high demand, prices may spike, while during economic downturns, discounts or lower prices may be available to clear out inventory.

6. Optional Accessories and Upgrades Many suppliers offer optional features such as enhanced dust collection systems, upgraded software for monitoring, and additional tooling. These supplements often lead to a higher total cost.

centerless grinder price supplier

Choosing the Right Supplier

Now that we understand the factors that affect pricing, selecting a reliable supplier is critical to ensuring you get value for your investment. Here are some tips for choosing a centerless grinder supplier

1. Research Conduct thorough research on potential suppliers. Look at customer reviews, case studies, and testimonials to gauge their reputation in the market.

2. After-Sales Service Quality after-sales service can save you significant time and money. Check if the supplier offers comprehensive training for operating the machine, maintenance services, and easy access to replacement parts.

3. Customization Options If your project has specific needs, finding a supplier that offers customization options can be beneficial. This ensures that your machine is tailored to your unique requirements.

4. Warranty and Return Policy A robust warranty gives peace of mind about the investment. Always review the supplier’s warranty terms and return policy to understand your rights concerning repairs or replacements.

5. Direct Engagement Engaging directly with suppliers can provide insights into the price structure and help you negotiate better. Personal interaction also gives you a sense of their commitment to customer service.

Conclusion

In summary, purchasing a centerless grinder involves a multi-faceted consideration of price and supplier quality. By carefully evaluating the type of grinder you need, understanding the factors that influence pricing, and selecting a reputable supplier, you can make an informed decision that aligns with your production goals. Investing time in research and connecting with multiple suppliers can lead to finding a centerless grinder that not only fits your budget but also meets your machining requirements effectively.

-

Lidkoping Centerless Grinder - OEM Solutions & Discount PricingNewsMay.20,2025

-

High-Performance OEM Pipe Polishing Machines for Sale China DiscountNewsMay.20,2025

-

Premium SS Pipe Polishing Machines Best Price & Discount DealsNewsMay.19,2025

-

Handheld Pipe Polishing Machine OEM & Portable Design China SupplierNewsMay.19,2025

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025