The Role of OEM Metal Tube Polishing Machines in Modern Manufacturing

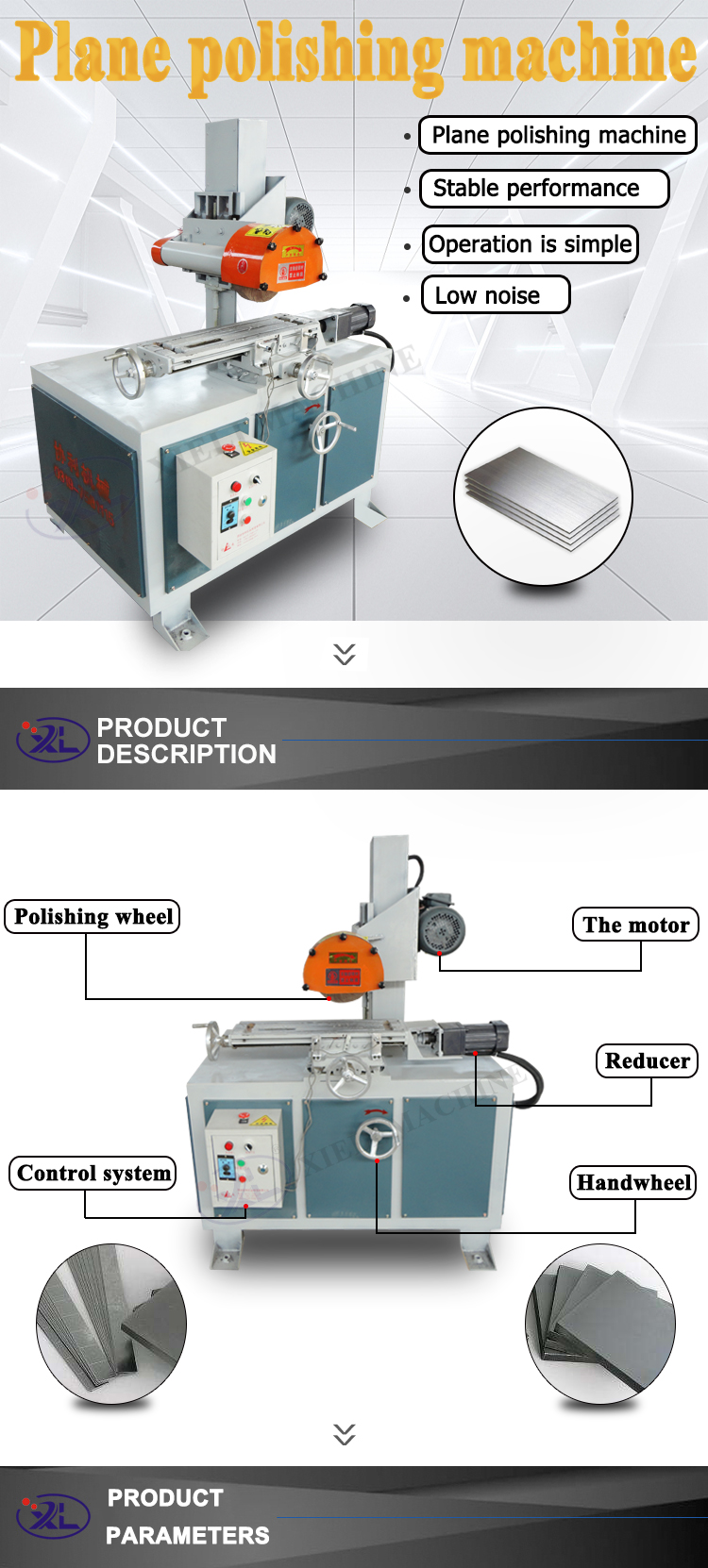

In the realm of metalworking and manufacturing, the finishing process is crucial for ensuring that products meet the required aesthetic and functional standards. One of the key players in this process is the OEM (Original Equipment Manufacturer) metal tube polishing machine. These machines are designed specifically to enhance the surface quality of metal tubes, providing a polished finish that is essential for various applications across different industries.

The Role of OEM Metal Tube Polishing Machines in Modern Manufacturing

One of the main advantages of using OEM machines is their customization. Manufacturers can work closely with OEM providers to design machines that cater to their specific needs. This includes adjustments for tube dimensions, material types, and desired finish quality. Such customization ensures optimal performance, leading to higher productivity and reduced operational costs.

oem metal tube polishing machine

Energy efficiency is another critical aspect of modern OEM metal tube polishing machines. With a growing emphasis on sustainability, manufacturers are increasingly seeking solutions that minimize energy consumption and waste. Many contemporary polishing machines are engineered with energy-saving features that not only reduce operational costs but also align with environmental regulations and standards.

Moreover, the reliability of OEM metal tube polishing machines contributes significantly to their appeal. High-quality machines are built to endure rigorous manufacturing processes and are equipped with advanced monitoring and control systems. This ensures consistent performance, reducing downtime and maintenance costs, which are vital for maintaining production schedules.

In conclusion, OEM metal tube polishing machines play a pivotal role in the metalworking industry. By enhancing the aesthetic and functional properties of metal tubes, these machines contribute to the overall quality of the final products. Their adaptability, energy efficiency, and reliability make them indispensable tools for manufacturers aiming to thrive in today’s competitive market. As technology continues to advance, the importance of investing in high-quality polishing equipment will only grow, leading to even greater innovations in metal finishing processes.