The Evolution and Excellence of the Famous Micron Centerless Grinder

In the world of precision machining, centerless grinding has carved out a significant niche, particularly with the advent of the famous Micron centerless grinder. Known for its unparalleled precision and efficiency, this type of grinder has transformed how industries approach cylindrical grinding tasks. This article delves into the evolution, features, applications, and the technological significance of the Micron centerless grinder.

A Brief History of Centerless Grinding

Centerless grinding originated in the early 20th century as manufacturing processes began to demand more precision and efficiency. Traditional cylindrical grinding techniques required the workpiece to be supported between centers, which presented several limitations, including vibrational disturbances and setup complexities. Centerless grinding emerged as a solution, allowing for quicker production times and higher accuracy by using a support wheel to stabilize the workpiece.

Over the years, various innovations and advancements have led to the development of sophisticated centerless grinding machines. Among these, the Micron centerless grinder stands out for its precision engineering and reliability. Micron Technology, a pioneer in grinding solutions, has consistently pushed the boundaries of what is possible in the field, earning its equipment a reputation globally.

Features of Micron Centerless Grinders

One of the primary strengths of Micron centerless grinders is their ability to achieve extremely tight tolerances. These machines are designed to accommodate a range of materials and can grind components to tolerances as tight as ±0.0001 inches. This level of precision is essential for industries that require components to fit together seamlessly, such as in aerospace, automotive, and medical device manufacturing.

Micron grinders incorporate advanced features such as adjustable infeed and through-feed mechanisms, which allow operators to customize the grinding process to meet specific production requirements. The ability to easily adjust these settings contributes to higher efficiency and adaptability in production. Furthermore, the machines are designed for ease of use, with intuitive controls that can minimize operator training time.

Another hallmark of Micron centerless grinders is their robust construction and durability. Built to withstand rigorous industrial environments, these grinders are equipped with high-quality components that ensure longevity and stability during operation. This durability not only lowers maintenance costs but also enhances productivity by reducing downtime.

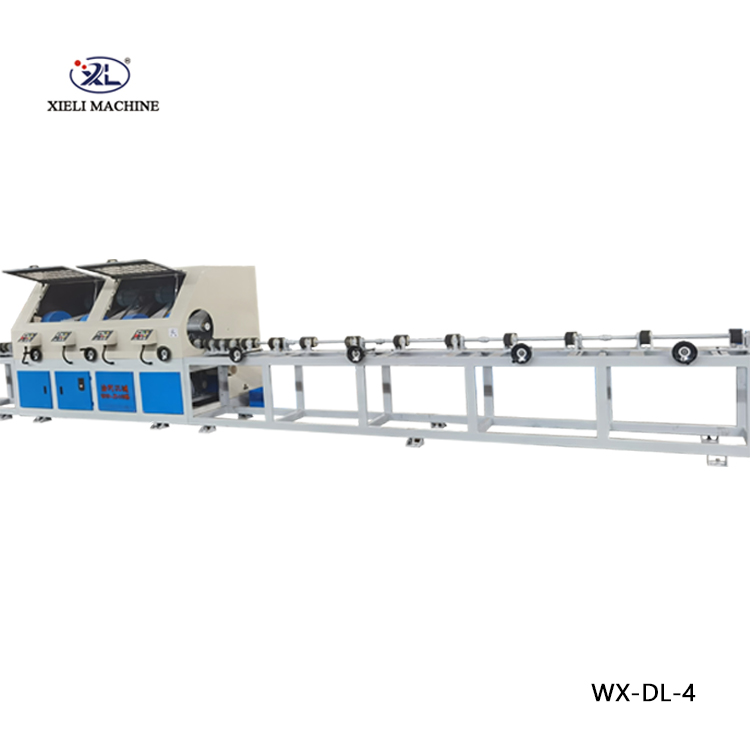

famous micron centerless grinder

Applications Across Industries

The versatility of Micron centerless grinders has made them indispensable across various sectors. In the automotive industry, for instance, they play a crucial role in producing precision components like shafts, rollers, and bushings. The ability to maintain precise tolerances ensures that parts function optimally within complex assemblies.

In the medical field, where component reliability is paramount, Micron grinders are utilized to manufacture critical components such as surgical instruments, implants, and diagnostic equipment. The precision offered by these machines ensures compliance with stringent industry standards and regulations.

Moreover, the aerospace industry relies heavily on Micron centerless grinders for producing high-performance engine components and critical fasteners. The exceptional accuracy and finished surface quality offered by these machines are essential for meeting the rigorous standards of aerospace applications.

Technological Significance

The advent of modern technology has also influenced the development of Micron centerless grinders. Integrating CNC (Computer Numerical Control) technology has allowed for increased automation and process control, leading to improved efficiency and reduced human error. Furthermore, real-time monitoring and feedback systems enable operators to fine-tune their processes, ensuring optimal performance throughout the machining cycle.

Additionally, advances in software have made it possible to simulate grinding processes digitally, allowing for better planning and reduced scrap rates. These technological enhancements not only contribute to cost savings for manufacturers but also enhance overall product quality.

Conclusion

The famous Micron centerless grinder embodies the pinnacle of precision grinding technology. Its exceptional features, versatility across industries, and the incorporation of cutting-edge technology make it a vital tool in modern manufacturing. As industries continue to evolve with increasing demands for accuracy and efficiency, the role of high-quality grinding machines like the Micron centerless grinder will undoubtedly remain central to the advancements in precision engineering. Through its dedication to excellence, Micron Technology continues to lead the way in providing solutions that meet the challenges of today and tomorrow.

-

High-Quality Centerless Grinder Wheels Discounts & China SuppliersNewsMay.15,2025

-

Precision Automatic Metal Polishing Machine OEM & Discount OptionsNewsMay.15,2025

-

High-Precision Round Tube Polishing Machine Best Discount ChinaNewsMay.14,2025

-

Precision Centerless Belt Grinder for Sale OEM & Discount OptionsNewsMay.14,2025

-

Precision Mikrosa Centerless Grinders OEM & Discount ModelsNewsMay.13,2025

-

High-Efficiency Automatic Tube Polishing Machine OEM & Discount DealsNewsMay.13,2025