The Evolution of Bend Tube Polishing Machines A Look Inside the Factory

In the world of manufacturing, achieving a flawless finish on metal products is often just as important as the functionality of the items themselves. This is particularly true in industries where aesthetics and durability play a critical role, such as in automotive, aerospace, and construction sectors. One essential component in achieving a perfect finish is the bend tube polishing machine, a powerhouse of technology specifically designed for processing and polishing bent tubes to achieve a high-quality surface finish.

Understanding Bend Tube Polishing Machines

Bend tube polishing machines are designed to polish tubes that have been bent or curved in various shapes. Unlike standard polishing machines, which may work on flat surfaces or straight items, these machines incorporate advanced technologies to cater to the complexities that come with bends in tubes. The primary function of these machines includes removing oxidation, scratches, and other imperfections, ultimately transforming a rough metal surface into a shiny, mirror-like finish.

The Manufacturing Process

Inside a bend tube polishing machine factory, the production process is a well-orchestrated symphony of technology and craftsmanship. The design of these machines typically begins with the latest computer-aided design (CAD) software, where engineers create precise models of the machines based on customer requirements and industry standards.

Once the designs are finalized, the manufacturing process starts. High-quality materials such as stainless steel, aluminum, and specialized alloys are sourced and cut to size. The machines are then constructed with a focus on durability and efficiency. Many factories utilize automation technologies, such as robotic arms, to streamline assembly and ensure consistency across products.

Technological Innovations in Polishing Machines

Over the years, bend tube polishing machines have undergone significant technological advancements. Modern machines now feature digital controls that allow operators to fine-tune the polishing process with incredible precision. For instance, features like variable speed settings and programmable polishing sequences enable operators to adjust parameters based on the specific type of material and the desired finish.

bend tube polishing machine factory

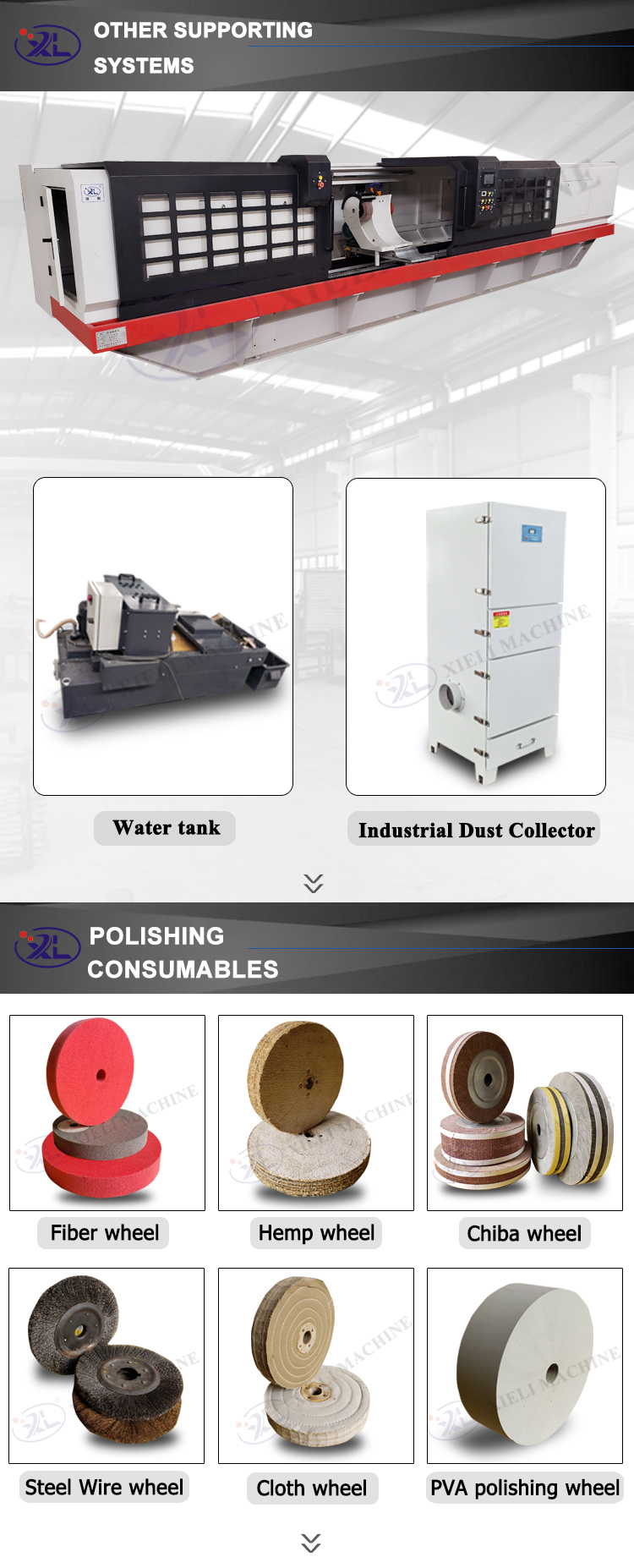

Additionally, advancements in abrasive technology have resulted in more efficient polishing outcomes. The use of advanced polishing compounds and tools designed specifically for working with bent tubes allows for not only a more refined finish but also a reduction in the time and labor costs associated with the polishing process.

Quality Control and Testing

Quality assurance is a critical step in the manufacturing of bend tube polishing machines. Each machine undergoes rigorous testing to ensure it meets the highest standards of performance and reliability. This testing includes evaluating the polishing effectiveness, durability, and precision. Factory teams often carry out trial runs and inspections, refining the machines until they are deemed ready for market.

The Importance of Customization

One of the standout features of modern bend tube polishing machine factories is their willingness to customize machines for specific customer needs. Industries vary widely in their requirements, from the size and shape of tubes to the exact finish desired. By offering tailored solutions, manufacturers not only enhance customer satisfaction but also position themselves as leaders in innovative engineering.

Sustainability in Manufacturing

The attention to sustainability practices in the manufacturing of bend tube polishing machines cannot be overlooked. Many factories are integrating eco-friendly materials and energy-efficient technologies, striving to reduce their carbon footprint. Furthermore, the evolution of water-based lubricants and biodegradable compounds for polishing contributes to a greener manufacturing process.

Conclusion

As industries continue to evolve, so too do the machines that support them. Bend tube polishing machines have emerged as an indispensable tool in producing high-quality metal products. The advanced manufacturing processes, technological innovations, and a commitment to quality and sustainability ensure that these machines meet the demands of modern industries. In a world where perfection is not just expected but demanded, bend tube polishing machine factories stand at the forefront, producing the tools that make it all possible.

-

Precision Centerless OD Grinder with Surface Attachment China OEMNewsJun.06,2025

-

Cincinnati Milacron Centerless Grinder High-Precision & DurableNewsJun.06,2025

-

Premium China OEM Internal Centerless Grinding Machine Discount PricingNewsJun.06,2025

-

Discounted Viking Centerless Grinder Sale OEM & China PrecisionNewsJun.06,2025

-

Precision Cincinnati Centerless Grinder - OEM, China, Discount OptionsNewsJun.06,2025

-

Paragon Centerless Grinder High Precision & Discount ModelsNewsJun.05,2025