Understanding Wholesale Filmatic for Centerless Grinder Machines

In the world of manufacturing, precision and efficiency are paramount. One significant machine that plays a crucial role in producing refined components is the centerless grinder. This machine is designed to grind cylindrical parts without the need for a dedicated fixture, making it an ideal solution for mass production environments. At the heart of centerless grinding operations are cutting tools and consumables that influence performance and quality, one of which is referred to as wholesale filmatic.

What is Wholesale Filament?

Wholesale filmatic refers to a specific type of grinding wheel and abrasive cloth used in centerless grinders. These products are often available in bulk from suppliers who specialize in grinding tools and machinery components. Filmatic generally describes the manufacturing process or the materials used to create these abrasives, ensuring they deliver superior performance under high-speed and high-pressure conditions.

The procurement of these components at wholesale prices presents a significant advantage for manufacturers. It enables businesses to reduce the per-unit cost of materials while ensuring that they maintain high quality, which is crucial for meeting industry standards and client specifications.

The Importance of Quality Filatic in Centerless Grinding

Centerless grinding relies heavily on the right abrasive materials. The filmatic grinding wheels provide unique advantages

1. Consistent Finish Wholesale filmatic products are engineered to deliver a consistent surface finish throughout the grinding process. This consistency is essential in manufacturing components that must fit together precisely.

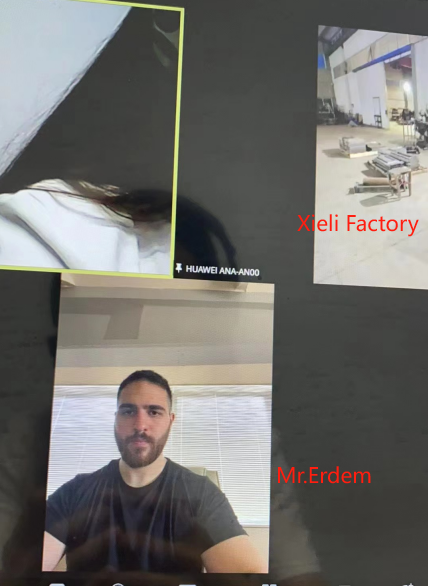

wholesale filmatic for centerless grinder machine

2. Enhanced Durability These grinding wheels are designed to endure the high stress and heat generated during the grinding process. Their durability reduces the frequency of wheel changes, contributing to increased operational efficiency and lower production costs.

3. Versatility Wholesale filmatic products can be tailored to suit various materials, including metals, plastics, and other composites. This versatility allows manufacturers to use the same type of grinding tool across different production lines, simplifying inventory management.

4. Improved Material Removal Rates The advanced abrasives found in wholesale filmatic products typically offer superior material removal rates compared to conventional grinding wheels. This efficiency can significantly speed up production, allowing manufacturers to reduce lead times and meet customer demands more effectively.

Choosing the Right Supplier

When selecting a supplier for wholesale filmatic products, manufacturers should consider several factors

- Reputation A reputable supplier with positive customer feedback ensures quality and reliability in products. - Product Range Suppliers that offer a wide range of abrasive products, including custom solutions, can cater to specific grinding needs effectively. - Pricing Structure Understanding the pricing structure, including any discounts for bulk purchases, can help with budgeting and cost management. - Delivery Times Timely delivery is crucial for maintaining production schedules. Establishing a supplier relationship that guarantees quick and reliable shipping can lead to smoother operations.

Conclusion

In conclusion, wholesale filmatic products for centerless grinder machines are integral to modern manufacturing processes. They provide enhanced performance, durability, and efficiency, contributing to the overall productivity of operations. As manufacturers strive for excellence in their production practices, investing in high-quality wholesale filmatic materials becomes not just a strategic decision but a necessary step towards achieving their manufacturing goals. By partnering with reputable suppliers, manufacturers can ensure they have access to the best abrasives, ultimately enabling them to produce top-notch components that meet the ever-evolving demands of the market.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025