Understanding CE Certification for Centerless Grinding Machine Parts

In the world of manufacturing and precision engineering, centerless grinding plays a crucial role in producing high-quality components. Centerless grinding is a method that allows for the efficient machining of cylindrical parts without the need for an additional center support. This technique has gained popularity across various industries, including automotive, aerospace, and medical, due to its ability to maintain tight tolerances and improve productivity. However, as with any industrial equipment, safety, performance, and compliance with regulations are paramount. This is where CE certification comes into play.

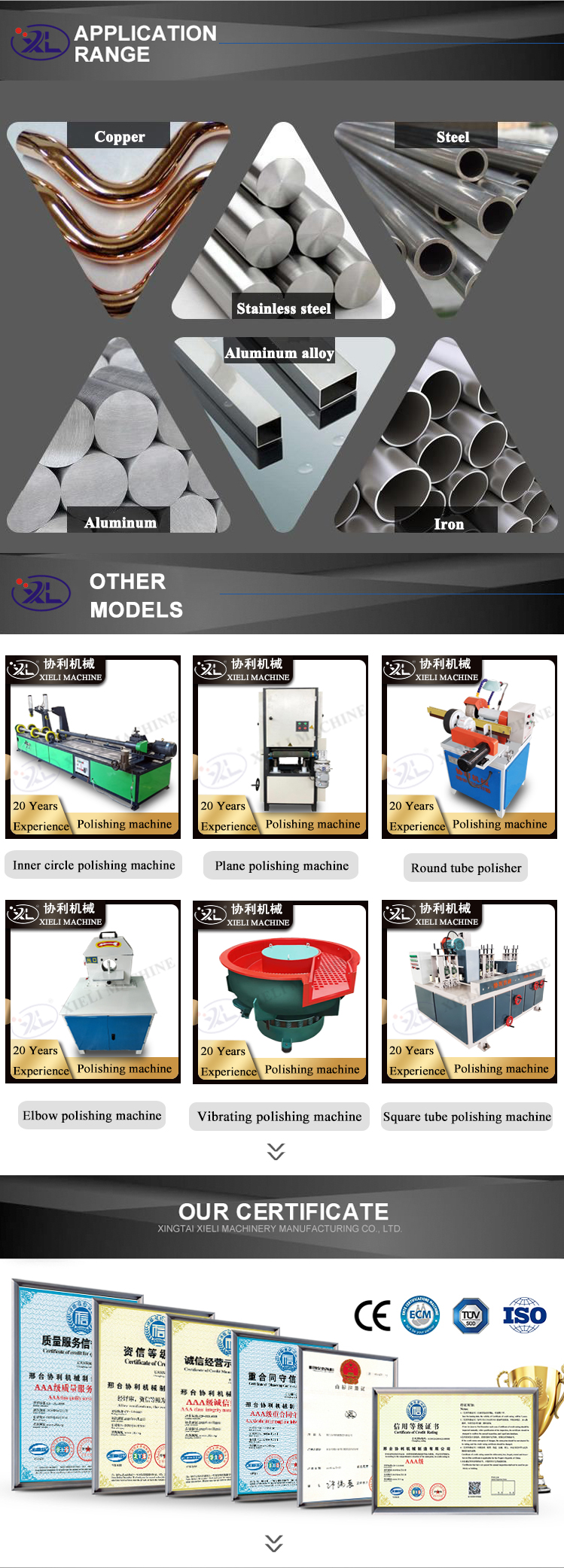

CE marking indicates that a product meets the essential health, safety, and environmental requirements set by the European Union (EU). For centerless grinding machine parts, achieving CE certification involves rigorous testing and adherence to established standards. Manufacturers must ensure that their products meet the directives pertaining to machine safety, electromagnetic compatibility, and other specific regulations that apply to grinding machinery.

One of the primary directives relevant to centerless grinding machines is the Machinery Directive (2006/42/EC). This directive outlines the safety requirements that manufacturers must comply with to minimize risks associated with the use of machinery. For example, guarding mechanisms, emergency stop functions, and user manuals are crucial components of a machine's design that must meet these regulations. The aim is to ensure that equipment is not only efficient but also safe for operators.

The process of obtaining CE certification for centerless grinding machine parts typically begins with a thorough product assessment. Manufacturers must conduct a risk analysis to identify potential hazards associated with the machine and its components. This involves evaluating mechanical risks, electrical hazards, and ergonomic concerns. Once risks are identified, manufacturers can implement protective measures and design features that mitigate these hazards.

ce certification centerless grinding machine parts

Testing and validation are also key steps in the certification process. This may involve third-party testing by accredited organizations that specialize in machinery safety. They evaluate the machine parts under various operating conditions to ensure compliance with EU directives. Once the product passes the required tests, manufacturers can affix the CE mark, indicating their commitment to safety and quality.

The implications of CE certification extend beyond compliance; it also serves as a marketing advantage. Customers in regulated markets often prioritize purchasing equipment that meets CE standards, as it reflects a commitment to safety, quality, and environmental responsibility. Manufacturers with CE-certified centerless grinding machine parts can gain credibility and differentiate themselves in a competitive industry.

Furthermore, CE certification facilitates access to the European market. In many cases, non-compliant products are not permitted for sale within EU countries, limiting potential business opportunities. Therefore, investing in CE certification not only enhances product safety and reliability but also opens doors to new markets and customer bases.

In conclusion, CE certification for centerless grinding machine parts is an essential aspect of modern manufacturing. It ensures adherence to safety and quality standards while providing manufacturers with a competitive edge in the global marketplace. By prioritizing compliance, manufacturers can build trust with customers and contribute to a safer working environment in the evolving landscape of industrial machinery.