The Rise of Bar Polishing Machines Revolutionizing Metal Finishing

In the world of manufacturing and metalworking, precision and quality are paramount. Among the various processes that ensure the best results in product quality, bar polishing stands out as a critical operation. This is where the bar polishing machine comes into play, a technological marvel that has transformed the way metal bars are finished. With the rise of automation and innovative technologies, bar polishing machine companies are shaping the future of metal processing.

Understanding Bar Polishing

Bar polishing refers to the process of refining the surface of metal bars to achieve a smooth, high-luster finish. This procedure is essential for various industries, including automotive, aerospace, construction, and more, where both aesthetics and performance are crucial. The polishing process can eliminate imperfections, improve corrosion resistance, and enhance the overall appearance of metal products.

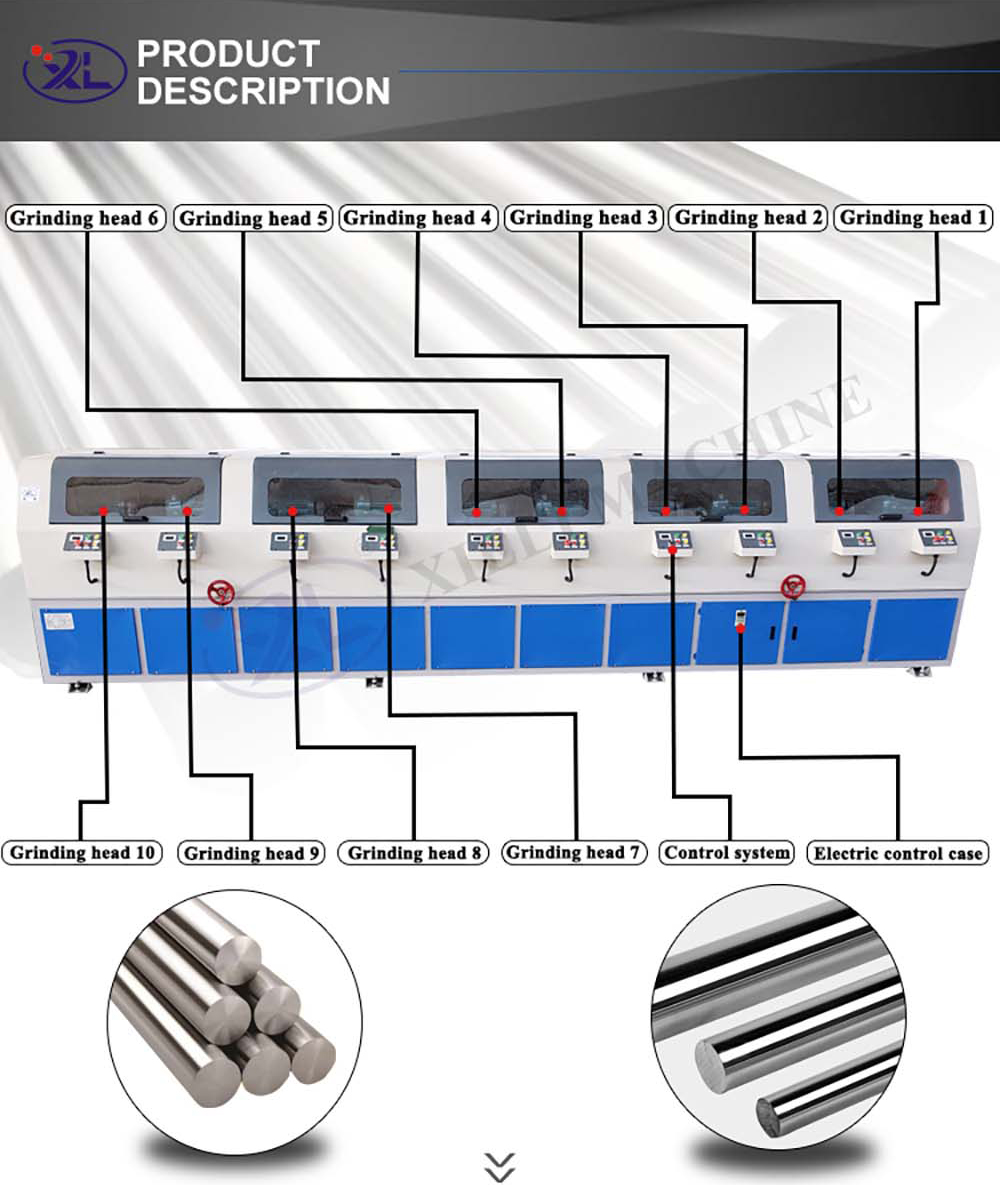

Bar polishing machines are designed to handle various sizes and types of bars, making them versatile tools for manufacturers. These machines can employ several polishing techniques, including mechanical polishing, chemical polishing, and electro-polishing, each offering distinct advantages depending on the material and desired finish.

The Role of Bar Polishing Machine Companies

Bar polishing machine companies play a pivotal role in the manufacturing sector by providing advanced polishing equipment tailored to the needs of their clients. The development and production of these machines require a deep understanding of metallurgy, engineering, and automation. As industries strive for greater efficiency and quality, these companies are at the forefront of technological advancements.

1. Innovation and Technology During the last decade, bar polishing machine companies have embraced automation and smart technologies to improve the efficiency of their machines. The integration of CNC (computer numerical control) technology allows for precise control over the polishing process, ensuring consistent results across batches. Additionally, advancements in materials and design have led to machines that are not only more efficient but also more durable, reducing downtime and maintenance costs.

bar polishing machine company

2. Customization Different industries have varied requirements when it comes to polishing finishes. Leading companies offer customization options tailored to specific needs, such as speed, finishing type, and automation level. This adaptability makes bar polishing machines indispensable tools in any manufacturing line, capable of handling everything from low-volume artisan production to high-volume industrial applications.

3. Sustainability As environmental concerns grow, bar polishing machine companies are also focusing on sustainability. Modern machines are designed to minimize waste and energy consumption. Many companies are now creating eco-friendly polishing solutions that reduce hazardous waste products, promote recycling of materials, and utilize green technologies in their operations.

4. Technical Support and Training The complexity of bar polishing machines often requires specialized knowledge for operation. Reputable companies not only sell machines but also provide extensive training and technical support. This ensures that manufacturers can fully utilize the capabilities of their machines and maintain optimal performance, thus maximizing their investment.

The Future of Bar Polishing Machines

As industries continue to evolve, the demand for high-quality metal finishes is expected to rise. The future of bar polishing machines looks promising, featuring continued innovations in automation, artificial intelligence, and advanced materials. We may soon see machines capable of detecting surface irregularities in real-time and adjusting polishing parameters on the fly, further enhancing precision.

Moreover, with the push towards Industry 4.0, the integration of IoT (Internet of Things) technology will allow for greater connectivity between machines and systems, providing manufacturers with valuable data analytics to optimize their polishing processes.

Conclusion

Bar polishing machine companies are driving significant advancements in the metalworking industry, bringing innovation, efficiency, and sustainability to the forefront. As manufacturing needs continue to evolve, these companies remain essential partners, ensuring that the quality and precision of metal products meet ever-increasing industry standards. The future of bar polishing is bright, and with the continued dedication of these companies, metal finishing will undoubtedly reach new heights of excellence.

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025

-

Monza 4 Centerless Grinder for Sale High Precision & Discount DealsNewsMay.16,2025

-

Fives Centerless Grinder Precision OEM Solutions & Discount PricingNewsMay.16,2025

-

High-Quality Centerless Grinder Wheels Discounts & China SuppliersNewsMay.15,2025