Understanding Centerless Grinding Machines by Jainnherr

Centerless grinding is a precision machining process that has gained remarkable importance across various industries, specifically for its efficiency and the high-quality finishes it provides. One of the notable contributors to this field is Jainnherr, a company specializing in centerless grinding machines that have become essential tools for manufacturers around the world.

What is Centerless Grinding?

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods, where the workpiece is held between two centers, centerless grinding holds the workpiece in place with a combination of a grinding wheel and a regulating wheel. This method allows for continuous production and the ability to grind multiple pieces in a single operation, making it an efficient choice for high-volume manufacturing.

Jainnherr's Innovative Products

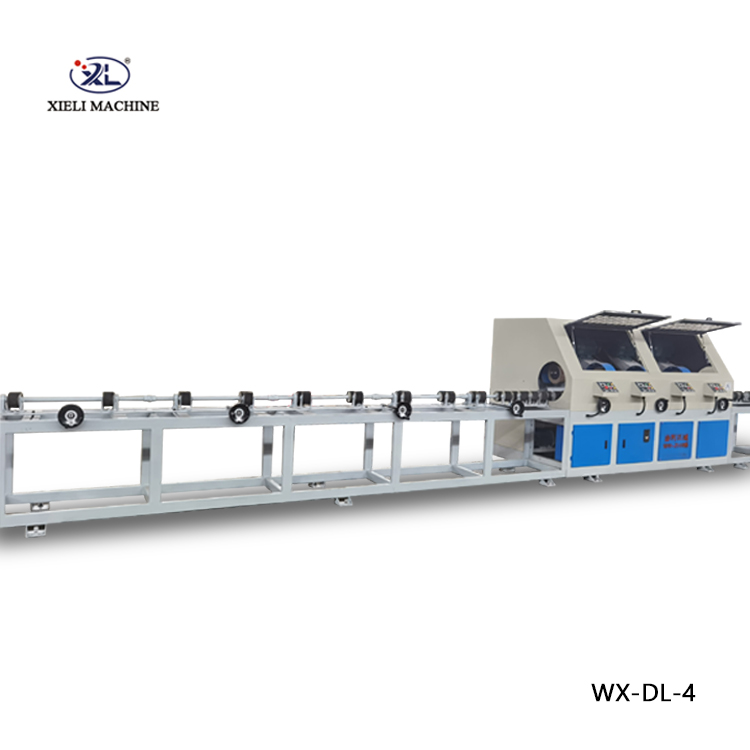

Jainnherr offers a range of centerless grinding machines designed to meet diverse manufacturing needs. Their machines are known for their robust construction, precision engineering, and advanced technology. The company's product line includes models that cater to both small-scale operations and large industrial applications.

One of the key features of Jainnherr’s centerless grinding machines is their adaptability. These machines can grind a variety of materials, including metals, plastics, and composites, making them versatile for different industries such as automotive, aerospace, and medical devices. This capability is crucial, as different applications often require specific tolerances and finishes that Jainnherr machines can provide.

jainnher centerless grinding machine products

Advantages of Jainnherr’s Centerless Grinding Machines

1. Efficiency Jainnherr machines are engineered for high-speed operations, which not only reduces cycle time but also increases productivity. The continuous feed system allows for an uninterrupted workflow, making it an optimal choice for large-scale production.

2. Precision Precision is paramount in machining. Jainnherr's grinding machines are equipped with advanced control systems that ensure tight tolerances and consistent output. This reliability is vital for industries where precision components are critical.

3. User-Friendly Designs Another significant advantage of Jainnherr’s products is their user-friendly interface. Operators can quickly become proficient with the machines, reducing training time and enabling faster implementation in production lines.

4. Maintenance and Support Jainnherr is committed to customer satisfaction, offering robust support and maintenance services. Regular maintenance keeps the machines running smoothly, minimizing downtime and enhancing the lifespan of the equipment.

Conclusion

In the realm of modern manufacturing, Jainnherr's centerless grinding machines stand out as a symbol of innovation and efficiency. Their machines not only streamline production processes but also ensure the highest quality standards are maintained. As industries continue to evolve, the demand for precision engineering solutions like those offered by Jainnherr will only grow. For manufacturers seeking reliable, efficient, and adaptable grinding solutions, Jainnherr's centerless grinding machines embody a choice that aligns with technological advancements and market needs. Whether for high-volume production or specialized applications, Jainnherr remains a leader in providing the tools necessary for success in the competitive landscape of machining.

-

Discount High-Precision Surface Polishing Machine Durable & EfficientNewsApr.29,2025

-

High-Precision SS Square Tube Polishing Machine China SupplierNewsApr.29,2025

-

Stainless Steel Square Pipe Polishing Machine OEM & High-EfficiencyNewsApr.28,2025

-

Centerless Grinder Troubleshooting Fast Fix for OEM, China & Discount ModelsNewsApr.28,2025

-

Centerless Grinder Automation Solutions OEM & Precision Systems ChinaNewsApr.28,2025

-

Scarlo Centerless Grinder OEM High-Precision China Models & DiscountsNewsApr.28,2025