Centerless Bar Grinding Machine Suppliers

In the world of manufacturing, precision and efficiency are paramount, especially when it comes to machining operations. One of the essential processes in the production of metal components is grinding, and centerless grinding stands out as a highly effective means of achieving precise dimensions and surface finishes. Centerless bar grinding machines play a critical role in this process, providing an unparalleled level of output and accuracy.

What is Centerless Grinding?

Centerless grinding is a method of removing material from a workpiece using a grinding wheel and a regulating wheel. Unlike traditional grinding methods, where the workpiece is held between centers, centerless grinding allows for the workpiece to be fed through the grinding wheels without any physical clamping. This unique setup provides several advantages, including continuous operation and the ability to grind parts with complex profiles and tight tolerances.

Benefits of Centerless Grinding

1. High Efficiency Centerless grinding machines are designed for high-speed operation. They can handle a greater number of workpieces without interruptions, thus significantly increasing productivity.

2. Precision These machines are capable of producing parts with very tight tolerances and perfect surface finishes, making them ideal for industries where precision is critical, such as aerospace, automotive, and medical devices.

3. Versatility Centerless grinding machines can grind various shapes and sizes of components, accommodating different materials, from metals to plastics. This versatility makes them suitable for a wide range of applications.

4. Reduced Setup Time The setup time for centerless grinding is typically shorter compared to traditional methods, which often require more complex fixturing. This adaptability can be a significant advantage for manufacturers looking to reduce lead times.

Choosing the Right Supplier

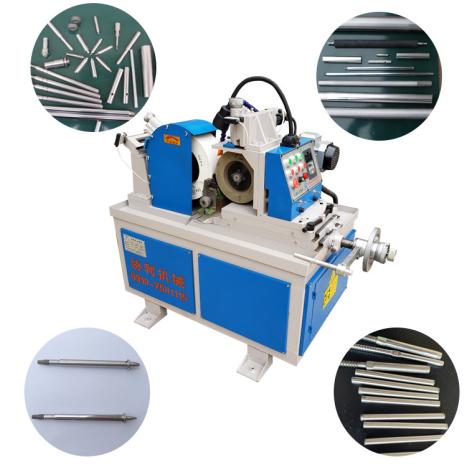

centerless bar grinding machine suppliers

When sourcing centerless bar grinding machines, it is vital to choose a supplier that possesses a strong reputation and extensive industry experience. A reliable supplier can offer not only high-quality machines but also valuable support in terms of installation, maintenance, and operator training.

1. Quality and Precision Look for suppliers that offer machines built with high-quality components. Machines with robust construction and high precision ensure consistent performance and durability.

2. Customization Options Since different manufacturers have varying needs, a good supplier will provide customizable options to tailor the machine specifications to the specific applications of the buyer.

3. Support Services A reputable supplier will offer comprehensive after-sales support, including maintenance services and the availability of spare parts. This support is crucial for minimizing downtime and ensuring long-term reliability.

4. Industry Experience Suppliers with a wealth of experience in the machining industry often have a deeper understanding of the specific needs and challenges faced by manufacturers. This expertise can aid in choosing the right machine and optimizing its use.

5. Customer Reviews and Case Studies Prioritize suppliers that can provide testimonials from satisfied customers or case studies demonstrating their machines' effectiveness across various applications. These insights are invaluable in making an informed decision.

Conclusion

Centerless bar grinding machines are an indispensable asset in modern manufacturing, providing unmatched efficiency and precision. As industries evolve and the demand for high-quality components increases, the role of these machines is set to grow even further. Therefore, engaging with reliable suppliers that offer quality machinery, customization options, and excellent support services is crucial for manufacturers aiming to enhance their production capabilities and maintain a competitive edge in the market.

By prioritizing quality and aligning with a reputable supplier, businesses can ensure that they invest in the tools required for success, paving the way for innovation and growth in an ever-changing industrial landscape.

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025

-

Sanworld Steel Tube Polishing Machine - OEM Precision & DurabilityNewsMay.18,2025

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025